المبنى 49، حديقة فومين الصناعية، قرية بينغهو، منطقة لونغغانغ

مغلق يوم الأحد

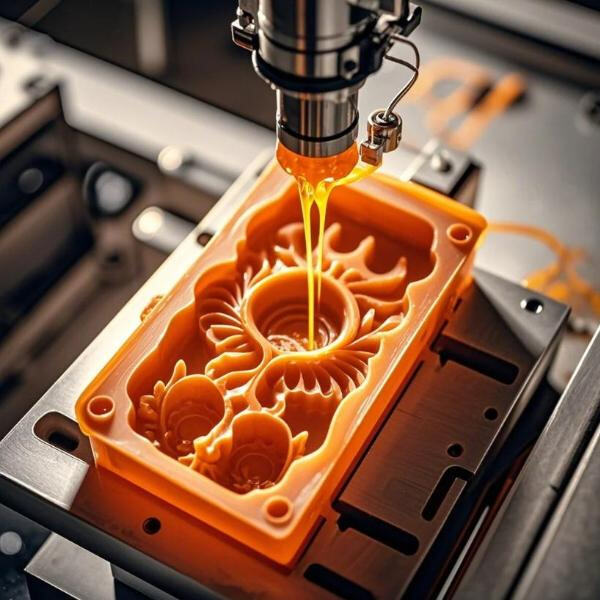

التشكيل بالحقن البلاستيكي هو أسلوب يستخدم لتصنيع منتجات بلاستيكية مختلفة. يستخدم البلاستيك المذاب، والذي يتم صبه في قالب لإعطاء أشكال مختلفة. في البداية، تُوضع حبيبات البلاستيك في برميل تم تسخينه. باستخدام الحرارة لذوبان البلاستيك إلى سائل كثيف. ثم يُحقن هذا البلاستيك السائل تحت ضغط عالٍ جدًا في القالب. القالب هو شكل مجوف يحدد الشكل النهائي للبلاستيك. يفتح القالب ويسمح بإزالة المنتج النهائي بعد أن يبرد البلاستيك ويتصلب. هذه العملية فعّالة للغاية حيث يمكن باستخدام طريقة التشكيل بالحقن إنتاج ملايين القطع البلاستيكية التي تكون متطابقة تمامًا أو نسخًا منها خلال فترة زمنية قصيرة جدًا.

هناك العديد من المزايا في إنتاج منتجاتك بكميات كبيرة باستخدام تشكيل البلاستيك بالحقن. يمكن أن يكون هذا مفيدًا بطريقة أو بأخرى، لكن أكبر تطبيق هو السرعة التي يمكن بها إنشاء الأشياء. فهو يتمتع بكفاءة أعلى حيث يمكن لهذا العملية الإنتاجية تصنيع العديد من الأجزاء دفعة واحدة. هذه السرعة، بدورها، تقلل أيضًا من الوقت والتكاليف بالنسبة للمصنعين. يُنتج تشكيل الحقن أجزاءً قوية ومتينة. بالإضافة إلى ذلك، يمكن إنتاجها بلون وتشطيب متنوعين، مما يوفر للمساحات التصميمية الكثير من الخيارات للعمل عليها. هذه المرونة تجعل من الممكن للشركات إنتاج منتجات تلبي خصائص وتفضيلات العملاء المختلفين، وهذا هو السبب في أن العديد من الصناعات المختلفة تفضل تشكيل الحقن.

تتطلب عملية تشكيل البلاستيك بالحقن تصميمًا يضمن أن العملية ستعمل كما هو مخطط لها. هناك المزيد من الأمور التي يجب أخذها في الاعتبار عند تصميم منتج بلاستيكي، مثل أبعاد القالب، تدفق البلاستيك ونوع التقلص بعد تبريد الفراغ. وكل هذه العوامل تؤثر على فعالية العملية. من المهم أيضًا أن يأخذ المصممون في الاعتبار مظهر العلامة التجارية للمنتج، والقابلية للاستخدام، والاستمرارية. يمكن أن يؤدي إدارة الوقت المناسبة للمنتج إلى تحسينات عبر جميع مراحل عملية التصنيع. هذا يساعد ليس فقط الشركات المصنعة ولكن أيضًا يقدم خدمة كبيرة للمستهلكين حيث تصبح أوقات الإنتاج أسرع مع أسعار أقل وجودة أفضل بشكل عام للمنتج.

الاختيار الصحيح لنوع البلاستيك وجميع الإضافات ذات الصلة، كما يُطلق عليها، والذي يجعل منتجات مolding عالية الجودة بدون مشاكل هو أمر مهم جدًا. هناك آلاف أنواع البلاستيك، ولكل نوع قوة وضعف خاص به. على سبيل المثال، يمتلك البولي كربونات مقاومة تأثير عالية جدًا، مما يعني أنه لا يتحطم بسهولة عند ضربه بقوة كبيرة. أما البولي بروبيلين، فيتميز بمقاومته الكيميائية العالية، وهو السبب في استخدامه في العديد من المجالات. بالطبع، اختيار الإضافات المناسبة يمكن أن يعزز من خصائص البلاستيك ويزيد من قوته أو مرونته، بالإضافة إلى مساعدته في تغيير اللون. هذا الاهتمام بالتفاصيل يسمح للمصنعين بتحقيق الخصائص النهائية التي يسعون إليها في المنتجات pronte.

تُعتبر عملية تشكيل البلاستيك بالحقن عملية فعالة ودقيقة للغاية، لكن يمكن أن تتشكل عيوب أثناء الإنتاج. المشاكل الشائعة تشمل التشوه (حيث لا تحتفظ القطعة بأبعادها الصحيحة)، وعلامات التهدّم على السطح، والبلاستيك الزائد الذي يُسمى فلاش، والحقن القصير (حيث لا يدخل كمية كافية من البلاستيك لملء القالب). لمنع حدوث هذه المشكلات، يجب على الصانعين توخي الحذر. وهذا يتضمن تبريد القالب بشكل صحيح حتى يتماسك البلاستيك بشكل صحيح، وضبط ضغط الحقن للتأكد من تدفقه الجيد، وضمان محاذاة القالب بدقة قبل حقن البلاستيك. الحفاظ على الفحص الدوري للمعدات الإنتاجية سيؤدي حتمًا إلى تقليل العيوب، وكذلك الحفاظ على نظافة القوالب.

فريق الهندسة المهني في مجال صب البلاستيك دائمًا في حركة، وينتظر للرد بسرعة على استفساراتك. إنهم ذوو مهارة عالية ويملكون الخبرة اللازمة للتعامل مع مخاوفك. أجزاء مخصصة بدقة عالية في التحملات: +/-0.01 مم، منطقة خاصة: +/-0.005 مم.

نحن نقدم خدمات صب البلاستيك OEM وODM. الكمية الدنيا للطلب هي وحدة واحدة. يتم تسليم الأسعار خلال ثلاث ساعات. أما عينات الإنتاج فتستغرق من 1 إلى 3 أيام، بينما تتراوح فترة التسليم بالجملة بين 7 إلى 14 يومًا. طاقتنا الإنتاجية الشهرية تتجاوز 300,000 قطعة.

تشمل معداتنا الإنتاجية معدات ذات 3 محاور، و4 محاور، و5 محاور تصل إلى 6 محاور. نحن نقدم مجموعة متنوعة من قدرات المعالجة التي تشمل الخراطة، والفرز، والتنشير، والطحن، وقطع EDM وصب البلاستيك. نحن نتعامل مع مجموعة واسعة من المواد تشمل النحاس، والبرونز، والألومنيوم، والصلب، والفولاذ المقاوم للصدأ، والمواد المركبة، والبلاستيك، ونصنع أجزاء تناسب أي متطلبات صناعية.

لدينا صب الحقن البلاستيكي الحاصل على شهادة ISO9001، وشهادة ISO14001، وشهادة ISO45001، وشهادة ISO13485 الخاصة بالأجهزة الطبية، وشهادة AS9100 الخاصة بالطيران، وشهادة IATF16949 الخاصة بصناعة السيارات. يمكننا إنتاج أجزاء ميكانيكية، وأجزاء لصناعة السيارات، وأجزاء إلكترونية، وأجزاء لصناعة الطائرات والفضاء، وأجزاء للأجهزة الطبية، وأجزاء لمعدات الاتصالات، وأجزاء للطاقة الجديدة، وأجزاء لمنتجات البناء والمنزلية.

جميع الحقوق محفوظة © شركة شنتشن بيرفكت برسيزيون برودكتس المحدودة — سياسة الخصوصية—المدونة