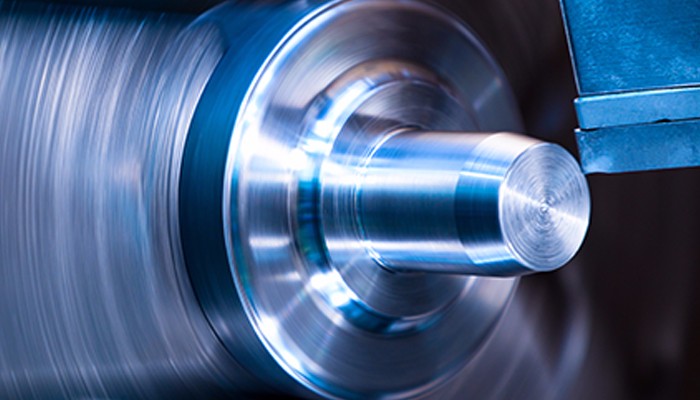

Computer Numerical Control (CNC) turning is a highly skilled, precision engineering process. It is an intricate and detailed method of creating custom parts and components using a turning lathe. which is used to make rotational parts by cutting away unwanted material.

CNC milling mainly includes plane milling and contour milling. Due to their versatility, CNC milling machines produce several items, including:

1. Prototypes

2. Spacers

3. Fittings

4. Shafts

5. Bushings

And more

CNC Turning process can be divided into rough turning, semi-precision turning, fine turning. The rough turning will use large cutting depth and large feed to improve the turning efficiency without reducing the cutting speed, so the machining precision can only reach to IT10, the surface roughness is Ra 20~10 micron, the semi-precision turning process and the fine turning will adopt the high speed and small feed and cutting depth, so the machining precision can reach IT8 to IT5, the surface roughness is Ra 1.6 to Ra 0.4 .

Accuracy: For many companies, the precision of CNC turning is one of its most competitive advantages. By incorporating CAD or CAM files into the process, machines can follow strict measurements and eliminate the waste of natural human errors.

Flexibility: CNC turning centers is their flexibility for your diverse applications, as they offer a range of size capabilities.

Repeatability: By producing product batches with unparalleled accuracy, CNC turning provides exceptional repeatability. That maximize its output and reduce its losses .

E-mail:dennis@7-swords.com