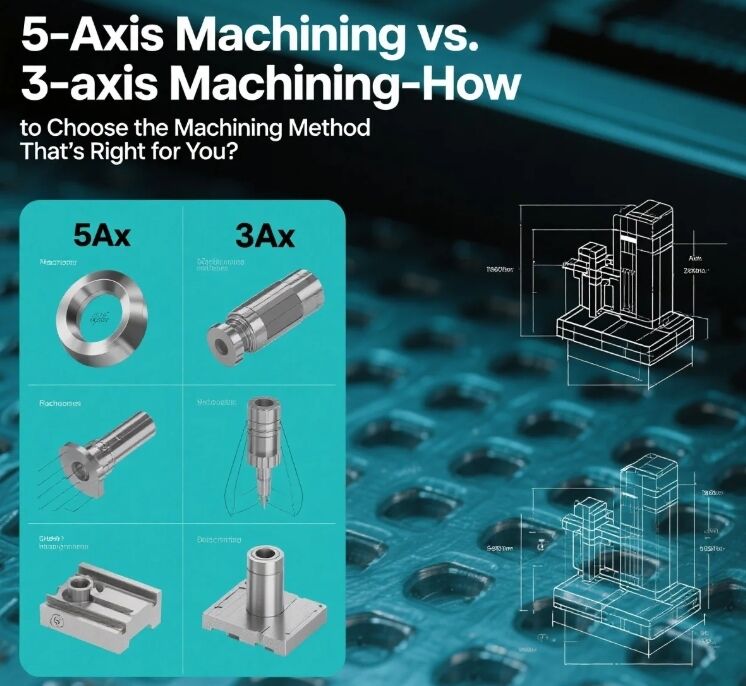

Чи знаходилися коли-небудь у ситуації, коли постачальник запитує: «Чи потрібна вам обробка на 3-осевому чи 5-осевому станку?» Розрив у ціні великий, але різниця здається неочевидною. Давайте розберемо це простими словами, щоб ви більше ніколи не переплатили.

1. Головна різниця: Все справа про рух

3-вісні машини працюють як розрізання тофу кухонним ножем — інструмент рухається тільки в трьох лінійних напрямках (X, Y, Z). Ідеально підходить для простих блоків або пластин, але обертати деталь вручну для багатосторонніх завдань? Скажіть привіт додатковому часу та помилкам у вирівнюванні.

5-вісні машини є схожими на роботизовані руки — вони додають два обертових віси (A/B/C) до інструмента або заготовки. Уявіть собі, як наклоняєте тофу під будь-яким кутом і розрізаєте криві без зусиль. Одна установка обробляє складні форми, косокутні отвори, лопатки турбін або вітрилки.

2. 5-вісний vs. 3-вісний: П'ятиперкова перевірна список

A . Складність деталі

1.Оберіть 3-вісний, якщо:

- Проста геометрія (кути, плоскі пластини)

- ≤3 обробних поверхні (не потрібен нахил)

- Обмежений бюджет (3-вісний вартує на 30-50% дешевше за годину)

2.Переходьте до 5-осевого режиму, коли:

- Складні криві, вироби з підкресленнями або органічними формами (наприклад, медичні імплантати)

- Багатогранна обробка у одній установці (немає помилок при перепозиції)

- Дорогі матеріали (5-осова система зменшує витрати титану/Інкоцеля)

2. Час vs. Бюджет

3-вісний вимагає перевороту деталей та зміни інструментів для складних завдань — додає 30%+ часу. Але для простих деталей? 3-вісний перемогає (дешевше запускати кілька машин).

3. Перевірка вартості

- Ціна апарату : 5-вісний = 2-3х вартість 3-вісного + дорожчий сервіс.

- Годинна ставка : 5-вісний заряджатиме більше, але загальна вартість може зменшитися для складних деталей (економить працю/час).

- Порада експерта : Виділяйте 5-вісній обробці для малих партій; купуйте 3-вісний, якщо масово виробляєте прості деталі.

4. Потреби точності

тolerances 3-вісної спадають при багатьох налаштуваннях (±0.1мм). 5-вісна підтримує ±0.02мм за один раз. Аерокосмічна галузь чи мікромолди? 5-вісна незамінна.

5. Вміння має значення

3-вісний: Легко програмувати (можна навчити новачка за кілька днів).

5-вісний: Потрібне сучасне програмне забезпечення CAM та інженери — малі майстерні часто не мають необхідної експертизи.

3. Уникайте цих витратних помилок

- Не перестараннюйте : Прості деталі на 5-вісній = спалювання грошей.

- Пропустіть покупку 5-осевої, якщо : Низький обсяг замовлень — орендуйте час роботи верстату.

- Перевірте обидва : Проектуйте з 3-осовими та 5-осовими магазинами. Порівняйте якість/вартість перш ніж переходи до повного виробництва.

Таблиця швидких рішень

|

Сценарій |

Рішення |

|

Прості деталі + обмежений бюджет |

машинообробка з 3 осями |

|

Складні криві + висока точність |

обробка на 5-осевих станках |

|

Складність малих партій |

Виконати 5-осеву операцію за межами |

|

Масове виробництво простих деталей |

Власні 3-вісні машини |

Останній порада : Завжди уточнюйте малюнки з вашим постачальником та перевіряйте їх обладнання. Ржава 5-вісна машина або недосвідчений оператор можуть зруйнувати навіть найкращий дизайн!

(Усе ще замішаний? Надішліть нам малюнок вашої деталі — ми проаналізуємо його безкоштовно!)