Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

When you’re sourcing custom plastic parts, precision and reliability aren’t negotiable. At PFT, we’ve spent decades perfecting the art of advanced plastic injection molding for industries ranging from automotive to medical devices. Our secret? Cutting-edge technology, obsessive quality control, and deep expertise in engineering-grade materials like ABS, Nylon, and PP.

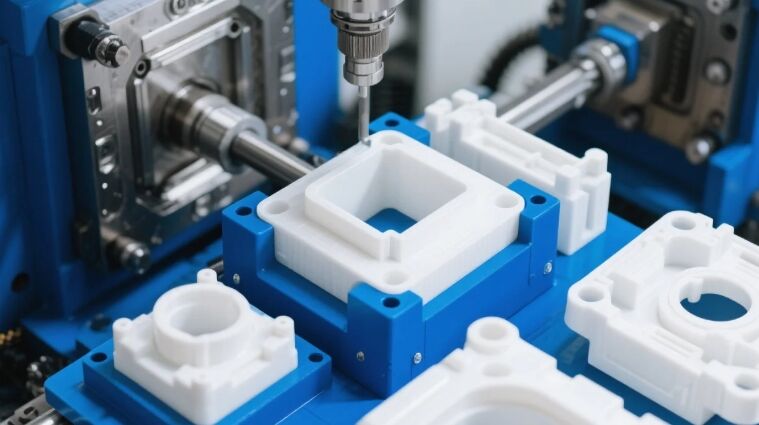

State-of-the-Art Equipment

We run fully automated, all-electric injection presses (up to 4,000-ton clamping force) for micron-level accuracy. Unlike older hydraulic systems, our machines reduce energy use by 60% while achieving ±0.01mm tolerances—critical for aerospace or medical components. Hybrid molding capabilities let us handle everything from ultrathin walls (<0.5mm) to complex geometries without flash or sink marks.

Material Mastery: ABS, Nylon, PP & Beyond

Fun fact: PP’s bend endurance allows hinge designs surviving 500k+ cycles—think snap-fit containers or living hinges.

Zero-Defect Quality System

Every batch undergoes:

Sustainable Manufacturing

Our closed-loop recycling reprocesses 99% of sprue waste into new feedstock. For eco-conscious clients, we offer bio-based Nylon and recycled PP options without compromising ductility .

Case in point: A recent project for EV battery housings used glass-filled Nylon 66 to cut weight by 30% vs. aluminum—passing 15G crash tests.

Q: Can you handle low-volume prototyping?

Absolutely! Our quick-turn tooling division delivers 50–5,000 units in 2–3 weeks using modular molds.

Q: How do you ensure consistency across batches?

We document every parameter—from screw rpm to cooling time—in a digital twin system. Change one variable? The AI predicts outcomes before production.

Beyond specs, we focus on collaboration. Our engineers review your CAD files upfront, suggesting design-for-manufacturing tweaks to slash costs by 20% on average. Plus, with in-house tooling maintenance, mold downtime drops by 40%

Ready to elevate your project? [Contact our team] for a free material selection guide and DFM analysis.

Processing |

CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding |

|||

Materials |

Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

|||

Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | ||||

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | ||||

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | ||||

Titanium: Grade F1-F5 | ||||

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | ||||

Surface Treatment |

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

|||

Tolerance |

±0.002 ~ ±0.005mm |

|||

Surface Roughness |

Min Ra 0.1~3.2

|

|||

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog