News

-

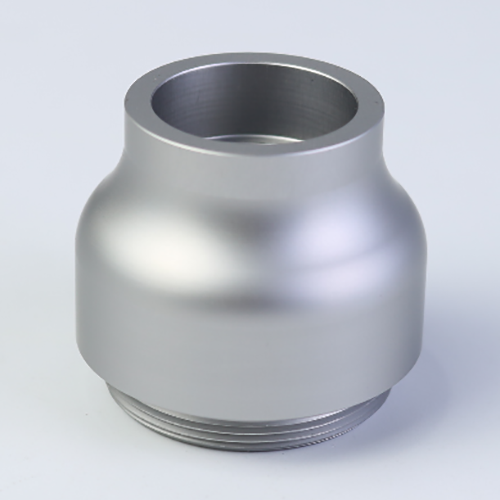

Precision Aluminum Components for Smart Manufacturing

As global manufacturing accelerates towards the stage of intelligence and high-end equipment manufacturing, the demand for precision components has also grown rapidly. A recently launched CNC-machined aluminum component, with advanced technology, sta...

Feb. 02. 2026 -

High-Precision CNC C45 Steel Black Parts

With the global manufacturing industry recovering and the acceleration of the trend of localizing and upgrading high-end equipment, the domestic precision processing supply chain is experiencing a new round of development opportunities. Against the b...

Feb. 01. 2026 -

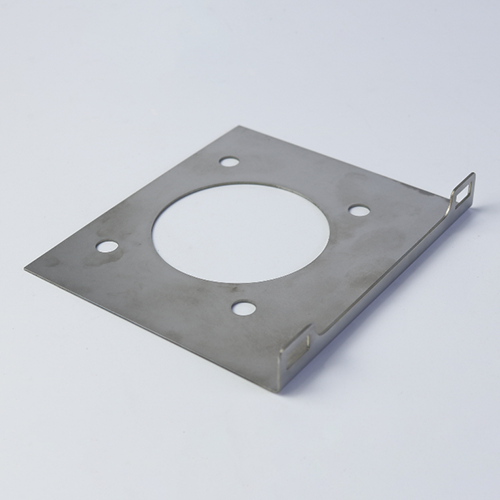

Ultra-Thin Stainless Steel for Advanced Manufacturing

As "new quality productive forces" has become the core driving force for industrial upgrading, the demand for precise, reliable, and rapidly iterative metal structural components in high-end equipment manufacturing, intelligent consumer electronics, ...

Jan. 23. 2026 -

Precision Aluminum Threaded Parts for New Energy

In the context of global efforts to promote the transition to green energy, the manufacturing of new energy vehicles and energy storage equipment has witnessed explosive growth. This wave has driven the demand for innovation in the upstream precision...

Jan. 22. 2026 -

Design Tips to Improve Accuracy of CNC Machining Parts

Learn proven CNC machining design tips to improve part accuracy, reduce tolerance issues, and lower manufacturing costs. A practical guide on how to design parts for CNC machining. Design Tips to Improve Accuracy of CNC Machining Parts Achieving hi...

Jan. 20. 2026 -

CNC Machining Parts Surface Finishing Guide: Anodizing, Black Oxide & More

A practical guide to CNC machining parts surface finishing, including anodizing, black oxide, and other treatments. Learn how to choose the right finish for durability, precision, and industrial performance. CNC Machining Parts Surface Finishing Gu...

Jan. 18. 2026 -

Low MOQ CNC Machining Parts: Why 1 Piece Production Matters for Prototyping

Discover why low MOQ CNC machining parts and one-off CNC machined parts are critical for fast prototyping. Learn how CNC prototype machining parts reduce cost, risk, and lead time for product development. Low MOQ CNC Machining Parts: Why 1-Piece Pr...

Jan. 16. 2026 -

How Much Do Custom CNC Machining Parts Cost in 2026?

Wondering about custom CNC machining parts cost in 2026? Learn CNC machining price per part, key cost factors, and how low volume CNC machining parts are priced. How Much Do Custom CNC Machining Parts Cost in 2026? As global manufacturing continues...

Jan. 14. 2026 -

Custom CNC Machining Parts for Automation Equipment — From Prototype to Production

Looking for reliable cnc machining parts for automation equipment? Learn why robotic CNC aluminum components are ideal, how to move from prototype to production, and what to ask an industrial cnc machined parts manufacturer. Includes DFM tips, toler...

Jan. 12. 2026 -

New CNC Turned Aluminum Parts for Advanced Manufacturing

In the context of the global manufacturing industry's continuous advancement towards high-end and intelligentization, high-quality CNC customized parts have become the core focus of international buyers. A recently launched CNC-machined aluminum part...

Jan. 08. 2026 -

High-Precision CNC Aluminum Parts for Fast Shifting Systems

In the context of the global manufacturing industry accelerating its transformation towards intelligence and precision, high-performance customized components are becoming an important foundation in the fields of machinery, automobiles, and sports eq...

Jan. 07. 2026 -

Precision CNC Milling of FR4 Parts for Electronics

Against the backdrop of the accelerated restructuring of the global electronics industry chain and the surging demand for high-performance insulating materials, an innovative precision CNC milling process for green FR4 epoxy resin boards is drawing i...

Jan. 05. 2026