Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Aluminum is a metal that can be formed in different shapes and sizes. This strong metal with very low density is ideal for thousands of products that we encounter every day. The skill and the practice needed to fashion aluminum into some of the functional articles we see in our surroundings. Getting aluminum into your desired shape is referred to as aluminum forging. That's what makes it an art — a whole lot of patience, delicate work, and extensive attention to the minor details.

Aluminum forging is beneficial in that it assists in the manufacture of long-lasting and durable aluminum products. Aluminium is a metallurgical system that becomes more resistant (even than newly formed) when heated and subsequently shaped to meet the desired specifications. That's a big deal, since we can now make aluminum into things that need to be super durable and withstand really high pressure. Airplane parts need to be incredibly tough so they can keep the components above safely, car parts must endure rigorously for durability and safety on the road, sports gear requires strength for regular wear and tear.

Aluminum forging is one of the most renowned type of products which is a best example of lightweight but solid strength. Aluminum fits a variety of applications, including aerospace components, automotive parts and even construction-related work. Aluminum forging also comes as a benefit since it is cheap. Due to the reduction of waste, less material used whilst forging acts as an advantage that can cut costs. As a result, it is possible for consumers to have aluminum forging products at a lower cost, making them within reach of more potential buyers.

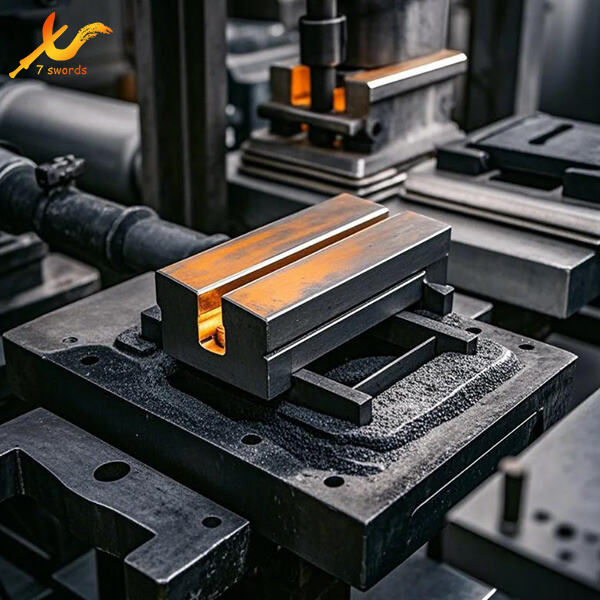

The process of forging aluminum necessitates to a great extent precision and engineering. What this really entails is that the metal needs to be heated to a precise level before it can be molded. A variety of tools and techniques are employed to mold the aluminum into its desired shape. They painstakingly engineer everything to guarantee that the end product is both devoid of defects and up to exacting standards. Not only that, but It also enables customization, which implies that every product may be created in accordance with the requirements of each customer. This is important because it allows for products to be made to precisely what the people want and need.

Aluminum is a very malleable metal, which allows it to be used in various applications. Forging enables us to experience the full possible capabilities of aluminum, allowing it to be shaped and formed into viable products for all of usa. Aluminum forging holds numerous roles in modern manufacturing — from parts in airplanes, to equipment used for sports. That the skill of forging aluminum enables many of those things we use in organised daily living.

The simply edged side of this packing case are folds when they have been heat handled, heat letting representatives to mix one more additional material including molding cold steel into discover. Years of experience and the inherent desire to keep things optimum quality has led us to engineering a tangential property with aluminum, stack them well in processing for precision.engineered products. We have professionals using the best tools and methods available to make products that are very effective, rugged and long lasting. Swords Precision has the know-how and experience to create what you need, whether you require specialised components for an aircraft or sports equipment that withstands the rigours of everyday use.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog