Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Aluminum CNC parts is a kind of device that is used very often in the production of various goods. Understanding what this machine does and how it helps factories is very much essential because they are actually the key that significantly improves the process of manufacturing.

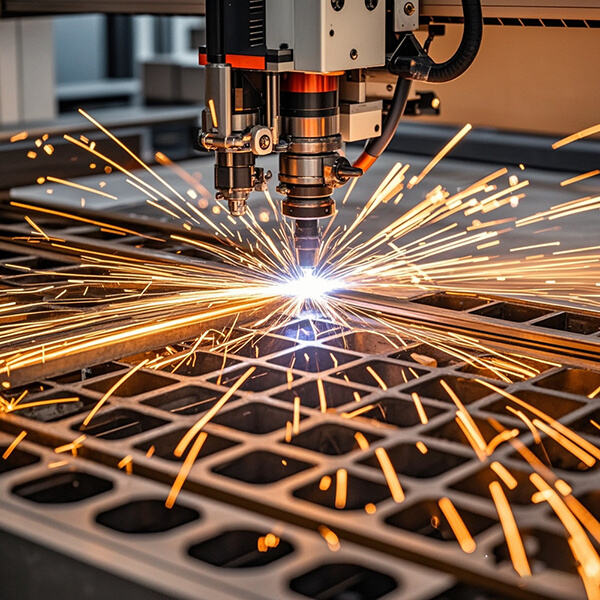

CNC plasma cutting is a process that utilizes a tool that produces extreme amounts of heat to cut through metal sheets. The tool generates what is referred to as an electric arc, a hot and bright bolt of electricity. This is the arc that heats up the metal, and it gives them a very high temperature. After that, a powerful jet of plasma gas blows the melted metal. This generates a nice and linear cut in the metal. This machine has a number of advantages for factories, including the facilitation of cutting and speeding the cutting process.

CNC machine components is mostly known for its ability to create very precise cuts into metal, which is largely why this form of technology has enremaed within the fabrication industry. This implies that it can slice through metal plates top quality. This is extremely crucial for factories as it ensures that the quality of the products produced are up to par. If the cuts are accurate, the final products will be able to fit well together and function as intended. In addition, the CNC plasma cutting machine can also be easily operated by a computer. In essence, it cuts its data again and again without faltering. This is useful in ensuring each and every piece gets it perfect.

CNC plasma cutting technology is one of the most versatile as it can process various types of metals. For instance, a laser robot can cut through aluminum, stainless and carbon steel with ease. Its ability to cut different metals allows it to be used in factories to produce a wide array of products for various needs. It is also capable of cutting through larger Gauge metal fabric so that it can produce stronger, durable and longer lasting products.

The professional CNC plasma cutting machine is also not just the above characteristics, but that it can be programmed to use different metal sheets for a long time without stopping. This allows factories to function more efficiently, as it does not require constant human supervision. Because it can run on multiple products at once, that helps factories manufacture more things quickly. In other words, organizations can sell additional products and at the same time earn higher revenues. This advantage of speed and efficiency is simply a boon to any manufacturing company.

CNC plasma cutter is the type of machine which uses heat and gas for cutting metal sheets. It generates an electric arc that rapidly heats and melts the metal, while the plasma gas removes this molten portion to produce a high-precision cut. CNC plasma cutting machine is a computer controlled machine that makes the same cuts, over and over, without mistakes. Not only does this technology allow for a bigger variety of metal to be used as well as thicker, more robust products. This enables factories to manufacture larger volume products in less time and Swiftly.

About {Company} Swords Precision products are made using state of the art CNC plasma cutting technology. We think this technology is the best way to serve our customers by building great products. We know that accuracy and efficiency in manufacture is critical. This is the reason we use CNC plasma cutting technology. It's our belief that this is the future of manufacturing, and in turn, enables us to deliver the best products to our customers.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog