Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Have you thought about making the gears of your bicycle or your favorite toy? It’s pretty interesting! Those key components are produced by gear companies such as Swords Precision. They produce different types of gears that support a variety of works in different industries.

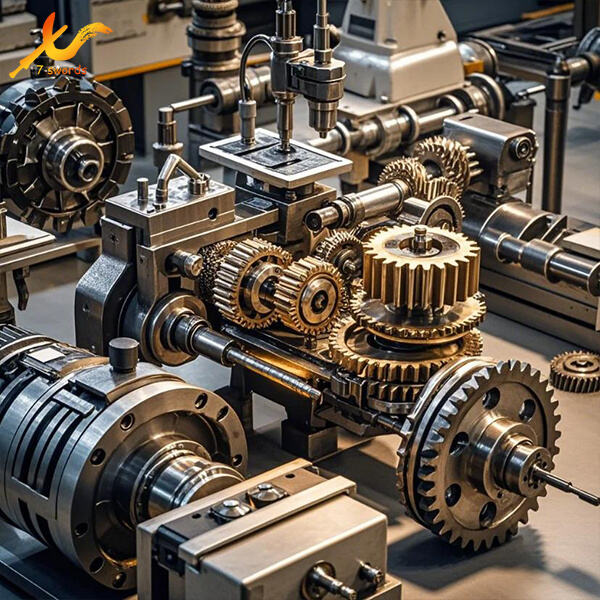

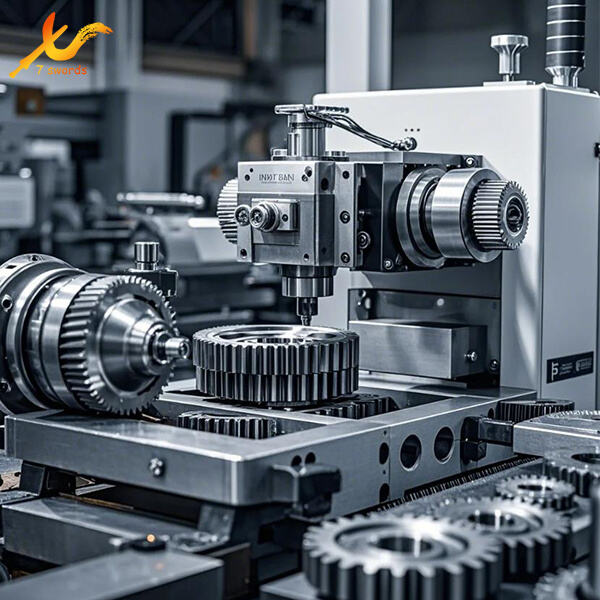

Swords Precision has some sort of touch to make efficient and durable gear. One of these techniques is referred to as hobbing. This technique involves using a tool known as a hob. The hobbing process is critical as it is the process whereby a hob actually cuts the teeth of the gear. Yet another way of describing this that they use is called broaching. In broaching, a different kind of tool (which is called a broach) needs to be used to manufacture the gear teeth singly. Also, this phase is extremely crucial as it provides a boundless method to generate the exact gear each time.

This allows gear companies like Swords Precision to produce even higher performance gears and faster than ever before. These require some specialized computer programs, specifically computer-aided design (CAD) and also computer-aided manufacturing (CAM). Gear makers can design the gears using CAD in the computer to ensure every detail is correct. Finally, CAM can rapidly convert the designs into physical gears. These programs assist gear makers to produce highly accurate gears and reduce manufacturing time. That translates into making more gears and bringing solutions to a larger set of customers quickly.

That gear companies such as Swords Precision remain indispensable in revolutionizing the production of things across various industries is a compelling reminder of that fact. They not only make better, more efficient gears, but they also improve the products of other businesses. Take, for instance, airplane and car manufacturers that require precision gears designed exactly to their specifications. Swords Precision manufactures bespoke gears specifically for these businesses. Such partnerships contributes to the overall improvement of the quality of product which these companies are providing for their users.

The rise in demand for businesses requiring gears means that organisations such as Swords Precision have been busier than ever recently. With increasing demands of improving the products by companies, it needs well fitted gears belonging to their point of contact. This has fueled the increasing need of gear companies that can deliver premium-quality & high-efficiency durable gears. These companies also still serve an important manufacturing role, as they do indeed grow.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog