Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

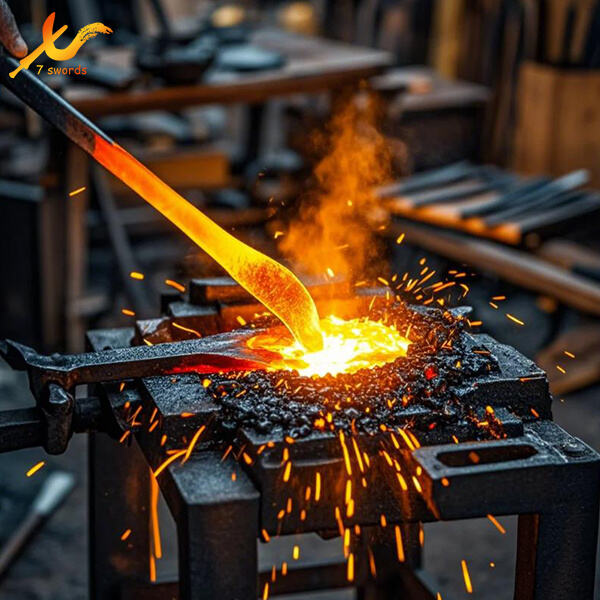

Hot forging resembles cooking a dinner to some degree. Heat is essential for cooking; it alters the state of food. Hot forging uses glowing red-hot metal, too. We hammer: heavy hammers and powerful presses reshaping the metal once hot. Similar to how a chef uses heat in cooking delicious recipes, we utilize heat and pressure to manufacture metal products that are functional and ever-lasting.

Using hot forging we manufacture all types of our products from swords, knives, to various type of tools at Swords Precision. These hot forged metal pieces are extremely strong. They are strong enough to withstand a lot of pressure and force without breaking. This is also the reason we prefer hot forged metal tools over any other material because these tools last long and work efficiently.

Hot forging is a conventional procedure used for thousands of years since antiquity. Hot forging has been an essential process in the metalworking industry since the days of blacksmiths working from small shops to today's use by thousands of metalworking factories. The skill and experience to perform this technique perfectly is a well-respected practice in the metalworking world.

This method of hot forging is the traditional way we at Swords Precision deal with this. We also employ seasoned craftsmen with decades of experience in this craft as part of our team. Over decades, they mastered the techniques and secrets of hot forging. This ancient method will, we believe, provide the highest quality metal products possible - and we also mean maximum strength/durability.

For many years hot forging has remained similar but with the advances in technology, hot forming has adapted and evolved accordingly. Historically blacksmiths shaped heated metal with hammers and anvils that they held in their hands. Nowadays we utilize hydraulic presses along with computer-controlled machines to hot forge our metal far more efficiently and accurately.

But despite all of these tools and technology, the same principles that drive hot forging continue to do so. Nonetheless, the process of making quality metal products still needs a lot of skill, precision and attention to detail. Here, at Swords Precision we make use of what are more traditional methods and modern technology to yield the best hot forged metal products on the market.

A combination of these three—temperature, pressure, and human skill—are extremely significant during the hot forging process here at Swords Precision. The temperature must be optimal to loosen up the metal for it to be without difficulty articulated. And if the temperature is low, then the metal will be hard and immiscible. If it is elevated, damage can occur.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog