Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

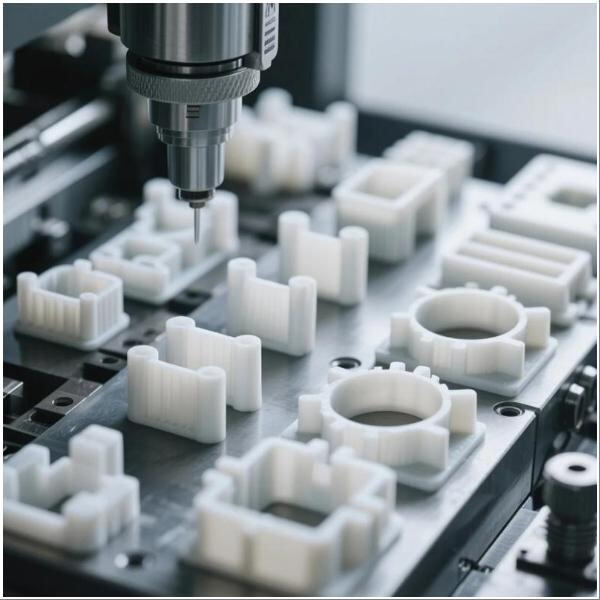

So what is injection molding in the real sense? So, it is a particular method for manufacturing products by forcing a material, usually some type of plastic, into a mold. Initial crude melting must take place in the material. That means it has to heat up a hell of a lot until the whole thing melts. A device then pushes the melted liquid material through a pinning system directly into a mold to create the final product. After you let the material cool and solidify, that right there is encapsulated in a mold, pull it out of the mould! That's it you now have a fully functioning product!

This is a fantastic process for designing products where consistency on each run is the main need. At Swords Precision, they leverage injection molding to manufacture everything from car parts and phone cases to critical medical equipment. Injection molding is what you want when you need that same thing that looks identical over and over!

Injection molding is great because it creates thousands of products quickly. The reason being multiple copies of the same design can be created simultaneously out of a single mold. Or, imagine the ability to create 100 car toys at the same time! Injection molding is capable of doing that. It also offers a lot of flexibility and adaptability. The interesting part is you can play with the materials, colors, and designs to create different products.

Now, some of you may believe that all injection molding does is create simple shapes — so untrue! This process can be used to make all sorts of complex and intricate parts. There are even multi-component molds that let you make moving or multicolored things in one go. This means that you can be really creative about what you create!

Tiny little things, like tiny gears that you might find in a watch to help keep time: injection molding can do that too. But you can also create much bigger things, such as body panels for a car that shield its interior. Incredible how it makes all kind of things, small and big! Its also possible to blend other materials together and form a completely new material that has different properties, features which can be extremely valuable.

Another thing to consider is the type of materials that you are using. Each material has a melting point which causes different materials to melt at different degrees. So, you need to select the appropriate material for your product so that it serves its purpose. It's also extremely important to verify that the material is being loaded correctly into the machine. In this way, we can ensure that the end product is uniform and up to our high standards.

Using the process of injection molding, we are able to make high quality repeatable products. It also means that car parts, medical equipment and other items are trustworthy (which is crucial for end-users). Also using injection molding allows us to create a more zero waste production as we can make only what is really necessary. It's good for our environment and it is a resource conservation.

We offer OEM and Injection Molding services Minimum order quantity is 1 piece Quotes are given within 3 hours Sample production takes 1 to three working days Delivery for bulk is 7-14 days Our monthly production exceeds 300 000

They have a wealth of experience and Injection Molding to address all your questions. Their extensive knowledge and expertise will help you solve your concerns. Custom high-precision partsTolerances: +/- 0.1 mm, Special Space: +/0.005 mm

We have ISO9001 certificate, ISO14001, ISO45001 Injection Molding ISO13485, aviation AS9100, Automobile IATF16949, we can produce mechanical parts, automobile parts, electronic parts, aerospace parts, medical device parts, communication equipment parts, new energy parts, construction and household products parts.

We have a range of Injection Molding equipment, ranging from 3-axis and 4-axis up to 6-axis. We offer a variety of processing capabilities that include turning, milling and drilling, grinding as well as EDM and 3D Printing. We deal with a wide range of materials such as aluminum, brass, copper steel, stainless steel, plastics, composites, crafting parts fitting to any industrial requirement.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog