Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

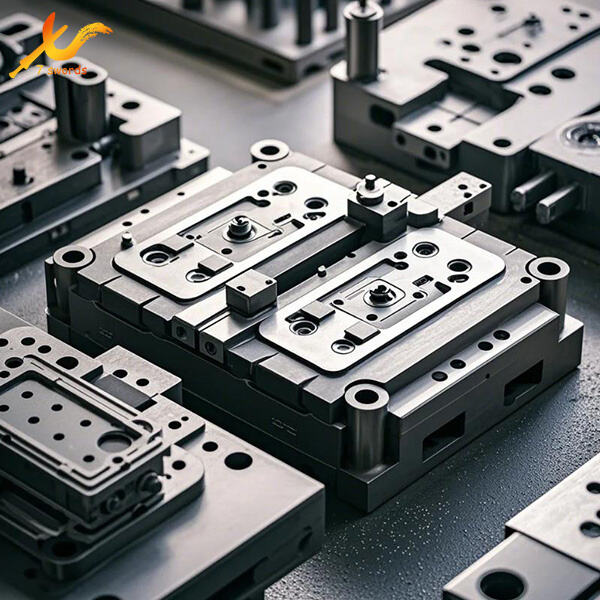

Injection moulds are specialised tools used to create plastic components for a wide range of products. They are also found in plastics such as those used to make toys, drinking cups and even auto parts. This is one of the reasons why injection moulds are famous, as they get these kind of parts in o lot easier and a much faster. Which means you can produce large quantities of products in a very short time frame using this method!

And how does this actually happen? Injection moulds require a specific type of machinery known as an injection molding machine. This machine has a crucial role to play. It gets plastic and heats them up till they become liquid. When the plastic melted, that machine forced it into a mold. A mould is a custom-made box that shapes the plastic. Once the plastic has been placed inside the mould it is allowed to cool. If it cools, then the thing has solidifies and it maintains a form of the mould. After it finally sets, the mould opens and out pops a ready-to-use plastic part. All of this takes place in a rapid sequence.

Select Correct Material: It is very crucial to always select the correct material when you are designing a mould. You have to ensure that the material can withstand high pressure during injection moulding.

Temperature Matters → Make sure that the mould is maintained at optimal temperature. If the mould is too hot, or too cold that would cause plastic to malfunction and therefore not leave the mould correctly.

Is there a proper setup of your machine: This should be the last point to think about, but do ensure that the injection molding machine itself is set up correctly. If the machine isn’t set correctly, it may not inject the plastic properly, resulting in parts that are not aesthetically pleasing or functional.

And the last one, but it is a game/game activity: it can emocionante! There are a lot of awesome things you can do with injection moulding, and also go wild with your creativity. You be amazed at what else you can create!

Injection moulding is much more than making toys and cups. It is similarly applied in several different fields. Injection moulding has few use in the medical field as well where syringes and catheters can be created, that are beneficial for mankind. The automotive industry utilises injection moulding process for making car components such as bumpers, dashboards and essential functioning parts for a car.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog