Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

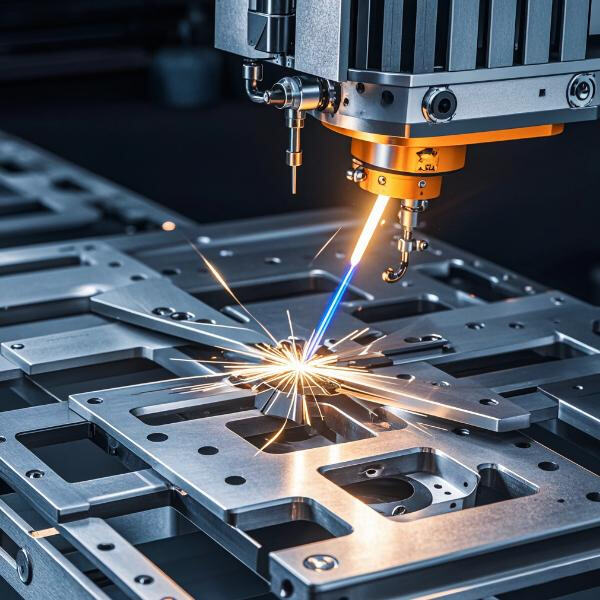

Aerospace precision parts is an awesome process that uses a high-powered laser beam to cut various materials. That is as if to use a wand to cut! One of the companies that implement this technology is Swords Precision, which manufactures some awesome items. In this article, we will explore laser cutting, its operating principles, and its role in transforming the product design process across industries.

For a very long time, laser cutting has been in the world. The first real laser came into being in 1960, actually! Meaning, scientists and engineers have been doing a lot of work on lasers over the years. Lasers developed into very powerful devices over the decades. Today, lasers can slice through metal, wood, plastic or fabric. It makes such design work simple because the laser beam is really precise. It creates beautiful shapes and patterns that are difficult to create using traditional cutting tools which benefits artists, designers.

Aluminum CNC parts is really good due to one big reason and that is accuracy. Using standard cutting tools, shapes and designs are difficult to achieve but the laser beam can cut shapes and create designs. Thanks to this accuracy, custom machine parts are created that fit very well, pretty jewelry creations with a special look, or even small model buildings in great detail.

Laser cutting also has the benefit of being quicker than other cutting techniques. With the ability to slice through materials at a pace and workers can manufacture more in less time. This is extremely crucial for companies which need to produce thousands of products in a relatively short time. Laser cutting allows companies to create high quality products faster and with less cost.

Lasers are powerful, and misused, they can be harmful. The flash of the laser beam can damage eyes if gazed into directly and closely approach can burn your skin. This is why ALWAYS adhering to safety guidelines when using a laser cutter is of utmost importance. Safety is an important part of what we do at Swords Precision. Supervise Employees on Usage — We ensure that all of our workers understand how to use the equipment safely and comply with safety guidelines.

We also survey customers what they actually need and that helps us to ensure our products are artistic as well as functional. In some cases, the customer knows what he is looking for and we will go to efforts in adopting those movements. That collaboration between designers and customers leads to the best products ever that people really enjoy.

Since laser cutting machines are quicker than previous cutting process, we cut out hundreds of items quickly and at lower prices. It is also more environmentally friendly because it produces less waste. Laser cutting is much more efficient with the material and helps minimize wastage, which in turn preserves our planet as traditional cutting methods often leave a lot of scraps behind after every cut.

OEM and ODM services are offered Laser cutting quantity is 1 piece We provide quotations within three hours Sample production requires 1 to 3 days Bulk delivery can take 7 to 14 days Our monthly production capacity exceeds 300 000 pieces

Our team of experienced engineers is always available, ready to respond Laser cutting to your inquiries. They have the expertise and knowledge to address all your concerns. Custom high precision partsTolerance: +/-0.01 mm, Special space: +/-0.005 mm.

We have ISO9001 certificate, ISO14001, ISO45001 Laser cutting ISO13485, aviation AS9100, Automobile IATF16949, we can produce mechanical parts, automobile parts, electronic parts, aerospace parts, medical device parts, communication equipment parts, new energy parts, construction and household products parts.

We offer a wide range of production Laser cutting, including 3-axis and 4-axis up to 6-axis. We offer a range of processing capabilities that include turning, milling, and drilling, grinding and EDM, 3D Printing. We work with many different materials like copper, brass and aluminum steel, stainless, plastics and composites.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog