Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

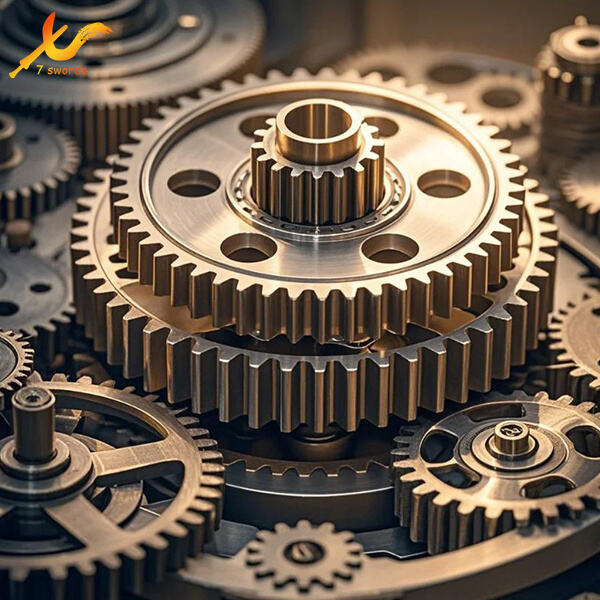

Aerospace precision parts are commonly found in mechanisms known as gear trains. A gear train is a team of gears that work together to transfer movement and energy from one part of a machine to another. It is similar to a chain of friends passing the ball. Every gear contributes towards keeping that ball rolling. Pinion gears are often the smallest gears in the train, but they perform a critical function. All seriousness, the gear train wouldn't work well without the use of pinion gears.

So how do pinion gears actually function? The teeth of pinion gears interlock with those on other wheels. They work together to transfer power from one gear to another at this point. Just like your teeth help you chew your food! Pinion gear teeth count — The pinion grasps onto as it passes power to other gears.

Another way that pinion gears serve to increase the speed of machines. Now, when you engineer two gears that have variable numbers of teeth as shown above, humourously, several things happen. A smaller gear will turn faster than a larger gear, so the larger gear on your bike is turning slower. This is also the reason why machines tend to perform much more efficiently when pinion gears are applied even though they are smaller in structure. Since the pinion gear rotates faster, it contributes to an overall higher speed of the whole machine!

There are some crucial considerations to make when choosing a pinion gear. One of the things that is important is the material of which the gear consists. Each material has their own pros and cons. Certain materials are extraordinarily strong, but also heavy, while some others will provide a less dense nature while sacrificing strength. So depending on what the machine is requiring we have to correctly choose the best material for it.

Well, and finally, one last thing to consider in the final gear is how many teeth does it have. More teeth also normally means the gear is capable of moving more power. On the other hand, more teeth makes for a heavier and more complex gear train. Striking a balance, that's the key!

Aluminum CNC parts, like any other component of a machine, require care and oil in order to function properly over the years. Gears can accumulate grime and dirt, making the gears worn out quickly. This creates issues of how the machine is used and, as a result, breaks it down altogether.

Pinion gears are found in various industries and applications. They, for instance, play a role in getting power from an engine transferred to the wheels in a car which permits it to move. They are used in wind turbines to transmit power between the spinning blades and the generator that generates electricity.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog