Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

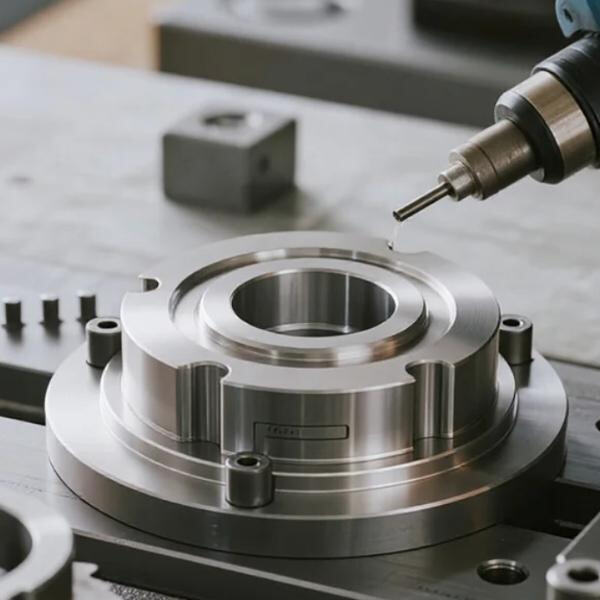

Swords Precision is a unique company that specializes in CNC machining of many parts. These CNC devices become in your respective places and ensure that you create the parts with all of the detail as if it were done by hand. Our hard-working employees utilize smart tools and newfangled technology to design & develop projects just the way they are meant to be.

It's kind of critical that when we design and produce a bespoke product for our customers, its accuracy matters greatly. But when you have CNC machines at your disposal, you can create the tiniest of features to extremely tight tolerances — down to 0.0003 inches in-app dimensions. This accuracy helps them to fit and assemble perfectly so that they work better and give the parts a longer and more smooth life without any complications.

One method that is employed frequently by our team is 5-axis machining. We have this as a separate operation because it property allows us to create very detailed parts all in one setup — better an more efficient approach. If we were to try and make such complex parts on a standard machine, it would very difficult indeed, but using 5-axis machining makes this much simpler.

The industries we serve with our CNC machining expertise are broad-based, including aerospace, automotive, defense and medical sectors among others. We make parts that not only meet, but often also surpass what our customers need or want, and we take pride in that. A dedication to quality that separates us from the rest of the pack.

Latest technology used in Swords Precision We continuously improve and update our equipment or software to make sure we can manufacture parts of the highest-grade. One of the tools we pay special attention to — as it is most important for us — is Computer-Aided Design (CAD) software. This software allows our builders to generate detailed plans and models which can then be sent directly to our CNC machines.

One other really big technology we are using is CAM (Computer-Aided Manufacturing) software. Our CNC software that controll all our CNC machines to make the manufacturing process smooth. With CAM software to program our machines precisely and quickly, we can manufacture components that are exactly what our clients need for their applications.

We maintain comprehensive documentation and tracking requirement as well. Because of this, when we manufactures parts they can be traced to the exact production lot that they came from and all machined components comes along within this product as well. This gives our customers confidence that they are getting top-off-the-line products for their money.

We provide Precision CNC Machining ODM services The minimum order amount is 1 piece We will provide quotes within 3 hours The production of samples takes 1 to 3 days while bulk delivery takes between 7 and 14 days Our monthly production capacity is greater than 300 000 pieces

We have ISO9001 certificate, ISO14001, Precision CNC Machining, medical ISO13485, aviation AS9100, Automobile IATF16949, we can produce mechanical parts, automobile parts, electronic parts, aerospace parts, medical device parts, communication equipment parts, new energy parts, construction and household products parts.

Our production equipment includes 3-axis (4-axis), 5-axis, up to 6-axis machines. We have a broad range of processing capabilities, including turning, milling, grinding, drilling as well as Precision CNC Machining, 3D Printing. We can work with a range of materials, including copper, aluminum, brass and stainless steel, plastics, composites and crafting components that meet any industrial need.

Our Precision CNC Machining engineering team is available 24/7, and ready to answer any questions you may have. They are highly skilled and have the experience to address your concerns. Custom parts with high precision tolerances: +/-0.01 mm, Special space: +/-0.005 mm.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog