Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

One of the most effective methods in construction buildings and bridges that are strong and safe is structural metal fabrication. It means getting metal to make other components that hold everything together. Work of this nature is undertaken by a company called Swords Precision. They specialize in manufacturing metal items such as beams, frame, and other necessary pieces that are needed for these strong constructions. These parts are needed for supporting the buildings and bridges we see every day without any problems.

Then what is the structural metal fabrication? It requires metal, to cut and bend the metal pieces as needed. Swords Precision employs a range of metals including steel, aluminum and titanium. These metals are selected for their unique characteristics, such as strength and durability. For instance, steel is super strong but aluminum is lighter and doesn't rust. Swords Precision employs these metals so that the parts constructed out of it are durable and capable to handle heavy loads.

To create a solid structure, every individual element must be built properly. And this is where technology comes in to play, Swords Precision employs special machines that are computer-controlled and ensure every component is manufactured exactly according to the specifications. The technique is known as precision fabrication. It helps to ensure that with five building or bridge parts fit very well, which is essential for it! When everything ultimately comes together this goes toward ensuring that everyone, who occupies the entire system is safe.

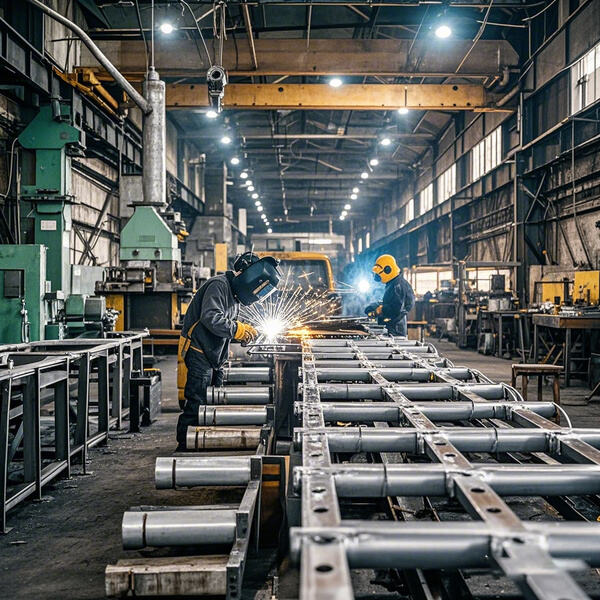

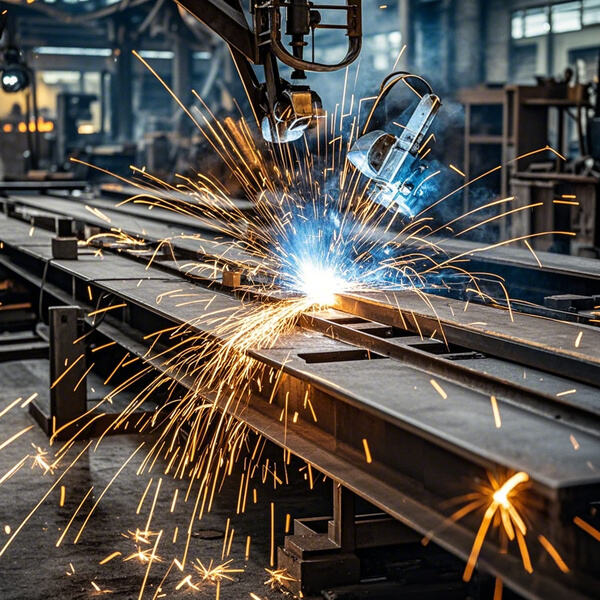

For their production, Swords Precision employs various methods to ensure that the finished metal parts are of high strength and stable structure. They are used to weld together bits of metal, for example. Welders melt two pieces of metal joining them together at their edges. This technique is crucial because it keeps the structure intact. They also use some heat treatment processes to treat the metal so it will be hardened and not rust easily. These techniques are crucial in maintaining the life-cycle of buildings and bridges without repair services.

You know by now that technology is always evolving and the latest innovations allow for quicker and more efficient structural metal fabrication. The machines operated in fine, precision measurements through computer programming and enabled Swords Precision to manufacture parts both quickly and accurately. With patience and practice, these machines can save time and cut metal with extreme accuracy. That entails making extra parts in shorter periods of time for the advantage of individuals all over – everybody wins.

One was this big metal sculpture that he made for a public park. Built of steel, this sculpture consisted intricate details that were crafted using the top-of-the-line laser cutting technology. This process will allow extremely precise designs that would be difficult to achieve using traditional methods. The sculpture was ornamental for the park and a demonstration of the metalworking abilities of company.

One of the more unique projects that was completed by Swords Precision over the years included building a metal-framed greenhouse. The challenge was to have a greenhouse that could support the heavy snow loads in winter but would still let lots of light in for the plants inside. Utilizing their structural metal fabrication techniques, Swords Precision crafted a design to accommodate these vital specifications. Through this project, It highlighted how conveniently metal can be moulded and used creatively for different purposes.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog