Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Well, titanium is a rare metal known for its strength and light weight. And it's even more powerful than a common metal such as steel, weighs much less! This specific combination of high density tensile and low unit weight momentum should be one of the deciding factor behind titanium for various applications. A nice thing about titanium is that it does not rust like most other metals. Thanks to all this cool stuff titanium can do, scientists and engineers really love working with it!

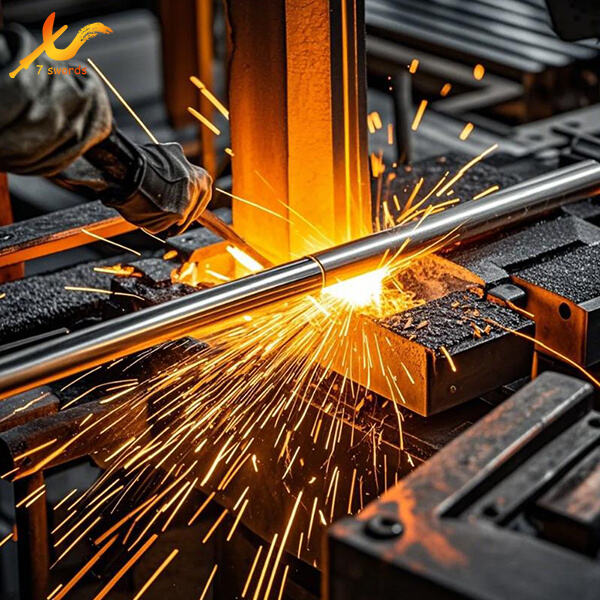

Titanium is typically made into stronger parts through forging. Forging means the metal is shaped using force, typically hammering it or a machine. It assists in bending the steel until it is specifically formed. Often referred to as “titanium forging”, this method of shaping the titanium is critical to generate strong and durable components.

What are the benefits of titanium as a forging? Titanium is a pretty tough metal to begin with. That toughness means it can withstand a lot of stress and pressure without deforming or breaking. Readily available, it is strong but lighter than air; thus vital in areas such as aerospace. It is important to save every pound in aerospace, so titanium is used for lightweight and more efficient airplanes and other vehicles.

Another major benefit of titanium forging is that, the parts made from it tend to be highly accurate. That means that the parts can be produced with extreme precision and uniformity — nearly an identical replica each time it is manufactured. It is pivotal in several applications where a minuscule error can end up being a significant inconvenience.

Control of the temperature of titanium metal is one important portion of titanium forging. This requires heating the titanium to a particular temperature which is called the forging temperature. While this temperature is capable of finding most metals, it is essential that this temp allows molding the metal without cracking and damage. A cooling metal process is also very important after shaping; it mitigates the risks of internal stress winding up in the metal and making the something brittle.

So, what would titanium forging be used for? This manifests itself most prominently and significantly in the aerospace space. This industry requires tough and low weight components, it is a must. Titanium is used in a lot of necessary components, including parts for engines and landing gear as well as structural supports. The components should be robust to resist the forces experienced during flight.

However, titanium forging applications are not limited to aerospace! In addition, titanium may be used in medical devices including hip replacements. The reason for this is that titanium has biocompatibility, meaning that it does not hurt and the human body can tolerate it. Also, because of titanium's lightweight properties, it is a preferred choice for medical devices that have to be functional yet comfortable in patients.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog