Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Swords Precision is a machine shop that builds large equipment to produce small parts. One particular operation they utilize is termed "Aerospace precision parts. It uses machines, heat and a lot of force to turn liquid metal into solids. Making parts that can be used in many different forms of machinery it smart and saves a lot of money. That is the most appealing thing about die casting, it can generate these components with both speed and accuracy. This means that even though the parts are small, craftsmanship and calibration goes into every piece.

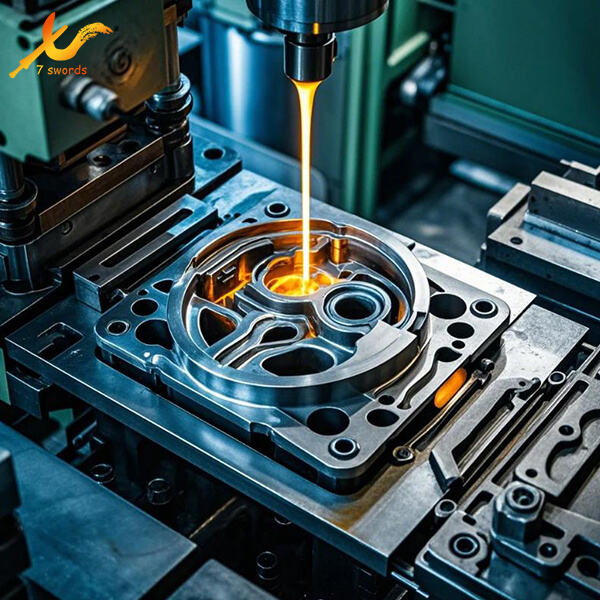

So how does die casting actually work? As a first step, you have to heat the liquid metal until it turns into a hot gooey substance. This step is critical; if the metal is not properly heated, it will not fill the mold. When the metal is melted, it is thrown to a special machine that helps us spoon the liquid into a mold. A mold is a custom design made specifically for the part that is to be produced. The hot liquid metal fills the mold, then cools, solidifying in the cavity. When it is no longer liquid, the machine opens and you can pull out the solid form. Sounds simple, right; but there are several steps that must be taken for everything to go as smoothly as possible. You want to make sure that every step is taken to ensure a desirable final product.

There are various ways to do Aluminum CNC parts, depending on what type of part needs to be casted. One way is what is referred to as hot chamber die casting. In this approach, the machine still contains a vessel filled with liquid metal, but Compare it to having a hot bowl of soup (while the mild taste just hits). Since the metal is already in the machine, parts can be made instantly without needing to refill the metal each time a new part is created. This allows for the process to be done quickly and smoothly.

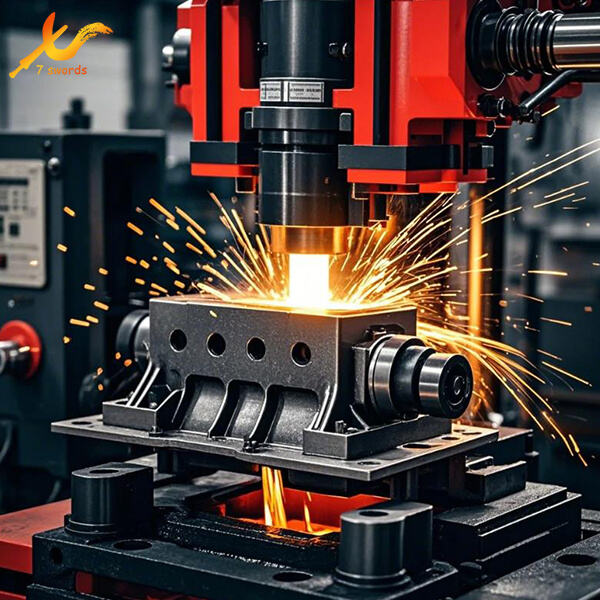

Another process is referred to as cold chamber die casting. The liquid metal is maintained outside the machine in this manner. When a part needs to be created, the metal is spooned into the machine. Better for metals that are not supposed to be heated too much. These methods have their own benefits, and Swords Precision knows what type of method should be used for each type of part to ensure it will turn out right.

Metal selection for die casting is highly critical. These metals are stronger and more suitable for components that are required to be something like those used in cars or airplanes. Lighter metals are ideal for components that should not be heavier than necessary (e.g., toys, electronic devices). Our experts at Swords Precision can help guide you to choose the best metal for your requirements. The metals include aluminum, magnesium and zinc, all of which are used in diverse applications to make stronger and lighter components.

Like many other technologies, die casting is not static but continually evolving. Swords Precision always staying up to date with the newest trends to provide you guys with the best parts available. Among them, the latest concepts involve employing robots for assistance in die casting. Robots can do things incredibly fast, making the process even more accurate! Production of such parts can be quicker and of better quality.

A spin-off of the trend is referred to as "green" die casting. It indicates machines are made to consume less energy and generate lower pollution. This is not just beneficial for the environment, with that they also saves cost to the organization. Swords Precision are constantly looking for ways to innovate and improve their processes. They want to do their part, and provide the best possible parts for as long-as-possible.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog