Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Have you ever wondered how common things like plastic cups, children toys or components of your car are produced? Initiation of all this process has a noteworth=> Aerospace precision parts! That is a special method for making things whereby heated plastic is poured into a one-of-a-kind shape, aka, mould. The plastic then hardens to whatever shape we want once it has cooled down. So lets dive into this process in a bit more detail!

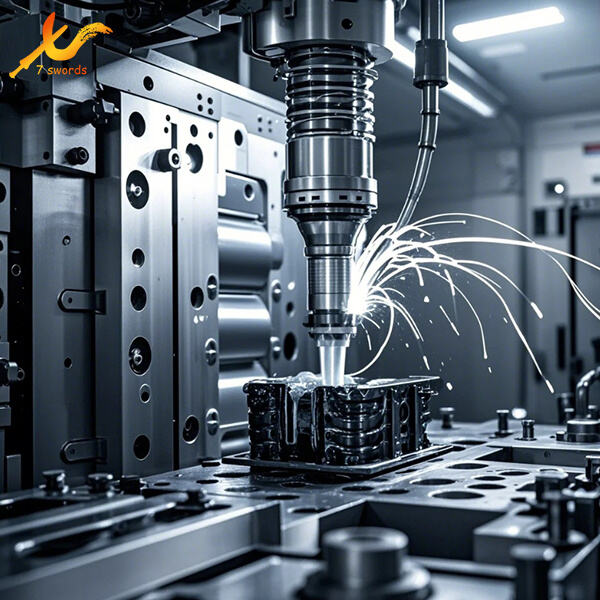

Designing and building the mould is usually the first step involved in producing a plastic item. A mould is a specialised metal container which serves to take the shape of melted plastic. Once the mould is prepared, small pieces of plastic known as pellets are loaded into a large machine called an injection molding machine. It then puts that mixture into a machine that heats it until the pellets turn to a viscous fluid. After melting the plastic, the machine forces it into the mould with great pressure. That allows the plastic to get into all corners of the mould. The heated plastic cools in the mould, then hardening to produce our desired final product within a matter of seconds.

Mould injection Molding is designed for manufacturing a large number of diverse products quickly and accurately. This enables manufacturers to create parts with very complex geometries. It is also because most of the work is done by machines that a lot of products can be manufactured simultaneously. This saves time and, in turn, lowers costs because it provides an inexpensive way to manufacture products when compared to other methods.

A variety of products can be manufactured using Aluminum CNC parts. It may also produce tiny elements such as buttons and clips, in addition to bigger components for the automobile, comprising bumpers along with dashboards. The method can be used to develop basic forms, such as cubes and spheres, but much more complex designs that require a high degree of precision. A huge advantage when it comes to mould injection molding is the variety of plastics that can be used. The temperature and pressure these things are able to work with can be altered in order to execute different materials — this process can produce when combined together final products that have distinct characteristics, including strength, flexibility or transparency.

There are multiple industries that utilize mould injection molding for their products. Automotive application–Used in making essential parts of the car like dashboard, door panel and also used for small pieces inside it. As an example, in the medical field it is used to produce syringes, inhalers and diagnostic items that are fundamental for health care. Mould injection molding also serves household equipment for creating supported parts such as refrigerator shelves, microwave components and dishwasher racks. This process is also used to manufacture things such as toys and packaging materials such as boxes, containers, etc.

Extensive range–Different sort of materials might be utilized in the mould injection procedure, which provides a broad variety of shapes, dimensions as well as special features.

Swords Precision is the best firm who offer injection moulding, high-quality products & quick turn around. Or if you would like to to learn how their expertise along this process can aid the success of your next project, reach out!

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog