Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Rapid prototype molding is a process enabling individuals to get small quantities of plastic components in really short time. The process has altered the manufacturing landscape and has enabled companies, such as Swords Precision, to conceptualise and manufacture new products quicker than ever. It is almost like a superpower for manufacturing.

However, these days with Aerospace precision parts companies such as Swords Precision can deliver a model within just 3 days! That’s a huge improvement! This allows them to test out a ton of different designs and iterate on them much faster than before. They can test an idea right away instead of waiting a long time to see if it works.

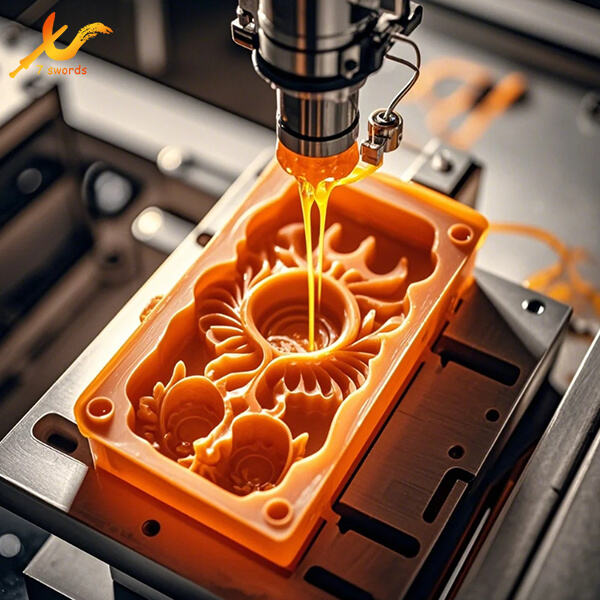

When the mold is finally constructed, another machine fills this template with liquid plastic. This plastic is extremely hot once poured inside, after which it cools down and hardens. When the plastic solidifies, the mold opens to access the part. This entire cycle can be repeated multiple times, so lots of parts can be quickly and cheaply produced. One of the best ways to create mass production with no time or money wastage!

In these and several other initial ways, Aluminum CNC parts is changing the face of modern-day manufacturing. This not only leads to the creation of new products, but does so much faster. That means they can answer to the customers almost instantly. The rapid rise in viral toys means that if one arises, companies can quickly generate others based on it.

Rapid prototype molding also allows organisations to experiment with multiple designs and implement modifications according to user feedback. As a result, the final product has a higher chance of being successful due to real customer feedback improving it along the way. Like having a testing squad to ensure everything is in place before the right to sell the product!

One more big benefit of rapid prototype molding is the possibility to produce short-run parts for a very low cost. This is especially valuable to businesses who may be required to produce a variety of unique components for a new item. They need not produce a ton of products all at once, but can just create what they require which minute.

Swords Precision can produce so many different parts to pieces that are made using rapid prototype molding. This allows them to experiment with different approaches and adjust their strategy in response to customer feedback and market conditions. This allows them to ensure that the product they are providing meets their customer needs.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog