المبنى 49، حديقة فومين الصناعية، قرية بينغهو، منطقة لونغغانغ

مغلق يوم الأحد

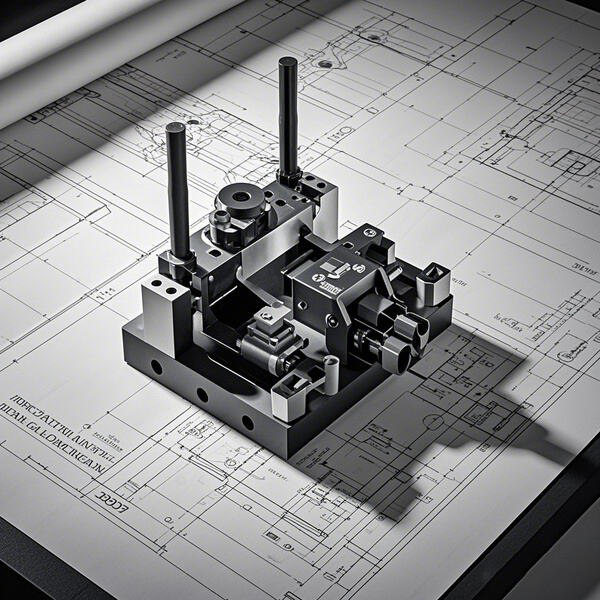

تقوم Swords Precision بإنشاء تصميم على أجهزة الكمبيوتر باستخدام برنامج CAD بمجرد تلقيهم طلب مشروع جديد. هنا يحتاجون إلى هذا البرنامج الخاص ليس فقط للتصميم ولكن أيضًا لاستعراض ما سيبدو عليه الكائن ثلاثي الأبعاد. يعتبر نموذج CAD عبارة عن صورة رقمية للعنصر الذي كانوا بصدد بنائه لهذه الدفعة الإنتاجية. إنه نموذج بالغ التفصيل، مما يتيح لهم مشاهدته من زوايا متعددة والتكبير لرؤية الميزات الصغيرة، حتى حجم كل شيء!

بمجرد أن يحصلوا على نموذجهم في نظام CAD، يمكن أن يكون من المفيد جدًا حساب أكثر طرق الإنتاج كفاءة للعنصر. يمكنهم رؤية كيفية تجميع جميع المكونات المختلفة ومعرفة الشكل النهائي الذي يجب أن يبدو عليه عند الانتهاء من التجميع. وهذا أمر أساسي لأنه يوفر الوقت ويقلل من التكاليف المرتبطة بعملية التجربة. لا حاجة لبناء نموذج حقيقي واختباره؛ يمكنهم إجراء جميع الاختبارات والتخطيطات على الكمبيوتر. هذا يعني أنهم يستطيعون إنجاز المزيد من العمل في وقت أقل وبجهد أقل!

تستخدم Swords Precision أيضًا أدوات تصميم CAD لتسريع عملية الإنتاج الخاصة بهم. تتيح هذه الأدوات لهم إجراء التصاميم بسرعة وبدقة، وهو ما لم يكن ممكنًا إذا تم تنفيذ جميع العناصر يدويًا. هذا يعتبر ميزة كبيرة لأنه يمكّنهم من إنجاز عملهم بشكل أسرع. في حال احتاجوا إلى إجراء أي تعديلات على التصميم، يمكنهم القيام بذلك بسهولة دون الحاجة للبدء من البداية.

لديهم أداة عملية جدًا تُعرف باسم معروف: التصميم المعلمي. أعتقد أن هذا أمر رائع لأنه يسمح لهم بتعديل التصميم في منطقة واحدة ورؤية فورية لكيفية تأثير هذا التغيير على النموذج بأكمله. لذلك، إذا أرادوا على سبيل المثال زيادة أو نقصان حفرة في جزء معين، يقوم البرنامج تلقائيًا بضبط جميع الأرقام المتعلقة بالقطع الأخرى التي يتم تركيبها. بدلاً من ذلك، يمكنهم تشغيل أدوات الإصلاح الآلية الخاصة بهم، مما يعني أنهم لن يحتاجوا إلى القيام بكل العمل الممل بأنفسهم، مما يوفر الكثير من الوقت.

يضعون أيضًا أهمية كبيرة على دقة نموذج CAD، لأنه سيساعدهم في تجنب الأخطاء أثناء مرحلة الإنتاج. يقوم برنامج خبير بدمج جميع القطع معًا للتحقق من توافقها الصحيح بحيث لا تواجه مفاجآت أثناء التجميع. سيوفرون الكثير من المال بعدم العودة وتصحيح الأخطاء التي كان يمكن تجنبها تمامًا منذ البداية، وكذلك الوقت.

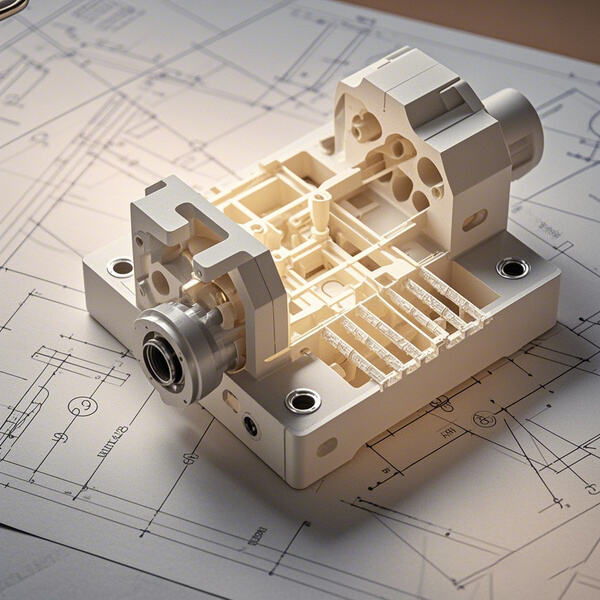

استخدام CAD في عملية التصنيع له فوائد عديدة. هذا بالتأكيد أكبر ميزة لأنه يوفر وقتك ومالك. لأنهم الآن يستطيعون إنشاء نماذج أولية لتصاميمهم بشكل أسرع وبمزيد من الدقة، تحتاج Swords Precision إلى عدد أقل من النماذج الأولية المادية. يقلل ذلك من المواد التي يحتاجون إلى شرائها ومن العمل اللازم، مما يوفر لهم ثروة في المدى الطويل.

بالإضافة إلى ذلك، يسمح تصميم CAD لهم بسهولة إنشاء تصاميم أكثر تعقيدًا وحتى تفاصيل دقيقة أكثر مما كان ممكنًا سابقًا. فهو يحتوي على برنامج قوي مناسب لإجراء حسابات معقدة وإنشاء عناصر التصميم، لذلك يمكنهم عمل أشياء كانت ستكون صعبة للغاية أو مستحيلة عند القيام بها يدويًا. الآن، هذا يعني أيضًا ابتكار وإبداع لا حدود لهما في مشاريعهم.

جميع الحقوق محفوظة © شركة شنتشن بيرفكت برسيزيون برودكتس المحدودة — سياسة الخصوصية—المدونة