المبنى 49، حديقة فومين الصناعية، قرية بينغهو، منطقة لونغغانغ

مغلق يوم الأحد

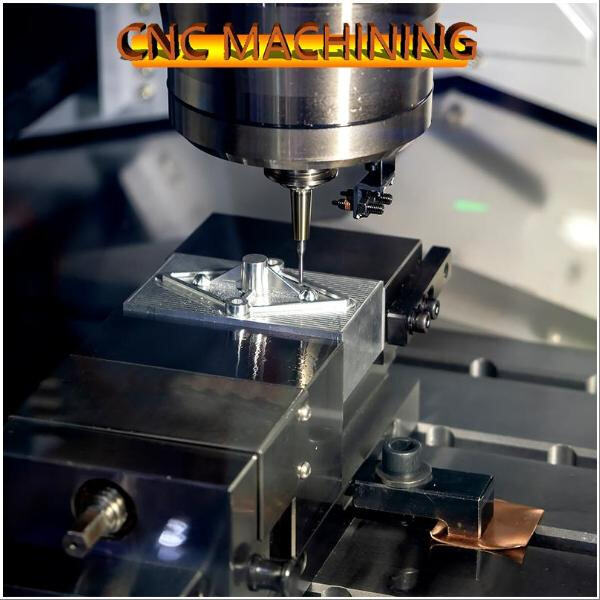

تشير عملية التصنيع باستخدام الحاسوب CNC إلى قطع الأجزاء من مختلف المواد، بما في ذلك المعدن والبلاستيك والخشب باستخدام آلات متحكم بها بواسطة الكمبيوتر. هذا هو مجال التخصص لشركة Swords Precision - حيث تنتج أجزاء دقيقة للغاية سواء كانت صغيرة أو كبيرة. يمكن وصف العملية على أنها قريبة من شكل من أشكال الفن، حيث يتم تحويل التصاميم الموجودة على الكمبيوتر إلى رمز محدد يتبعه الجهاز أثناء إنتاج المنتج المطلوب، سواء كان يحتوي على تفاصيل دقيقة أو مكونات ضخمة.

التصنيع بالتحكم المتحكم بالعدد هو مفتاح في مجال الطيران والفضاء والسيارات والرعاية الصحية. في مجال الطيران، تنتج أجزاء خفيفة وقوية جداً من أجل تحسين الطيران. في صناعة السيارات، تصنع مكونات محركات أساسية. في مجال الرعاية الصحية، تنتج التكنولوجيا أطقم اصطناعية مخصصة، ومعدات طبية، وغيرها الكثير من الأشياء التي تحسن حياة المرضى. هذه التكنولوجيا ستضمن الدقة والكفاءة في كل مكان

التصنيع بالإنترنت يتعلق بإنشاء شكل على الكمبيوتر أولاً، ثم السماح للإبداع بالدخول لإكمال التصميم. عندما ينتهي التصميم، يخرج الحاسوب رمزًا أجزاء تدوير CNC .. يقطع ويحفر ويمحور المعدن ليقوم بإزالة المادة بدقة لتحقيق الشكل الذي يحتاجه المرء هذا أشبه بقطع تمثال ولكن بدلاً من المنجل تقوم آلة بكل العمل بدقة وفعالية

هذه هي السمة Custom cnc parts , حيث يمكنهم إنشاء أشكال لا يمكن إنشاؤها يدويًا، أو التي يمكن أن تكون صعبة للغاية للإنشاء يدويًا. يمكنهم تصنيع العجلات ذات الأسنان المتشابكة - وهي ضرورية لتشغيل الآلات. و قطع بلاستيكية CNC يمكنهم أيضًا تصنيع زراعة الأسنان حسب الطلب لتتناسب بشكل مريح داخل فم الشخص، مما يفيد العديد من المرضى. لديهم طريقة دقيقة جدًا لقياس كل شيء للحصول على نتائج رائعة من الآلات. في الأساس، تقوم بإنشاء نموذج مستقل بحيث يتم إنتاج كل قطعة بدرجة عالية من الدقة.

الدقة العالية، والتي تتجاوز في معظم الحالات وسائل الإنتاج الأخرى، هي السبب في قيمة إنتاج أجزاء CNC بشكل كبير. في العديد من الصناعات، يمكن أن تؤدي مثل هذه الأخطاء الصغيرة إلى مشاكل كبيرة. التشغيل المستمر، 24/7، دون انقطاع لآلات CNC يمكّن من إنتاج كميات كبيرة من نفس العناصر. بالإضافة إلى ذلك، تكون كل القطع المصنعة موحدة، وبالتالي يتلقى العملاء منتجات متطابقة الجودة دائمًا.

لدينا شهادة ISO9001، ISO14001، ISO45001، الطبية ISO13485، تصنيع CNC AS9100، السيارات IATF16949، يمكننا إنتاج أجزاء ميكانيكية، أجزاء سيارات، أجزاء إلكترونية، أجزاء الطيران والفضاء، أجزاء أجهزة طبية، أجزاء معدات الاتصالات، أجزاء الطاقة الجديدة، وأجزاء البناء والمنتجات المنزلية.

يشمل إنتاجنا باستخدام CNC: ماكينات ذات 3 محاور، 4 محاور، 5 محاور وحتى ما يصل إلى 6 محاور. تشمل قدرات معالجتنا التدوير والتثقيب والطحن وEDM والطباعة ثلاثية الأبعاد وغيرها. نستخدم مجموعة متنوعة من المواد، بما في ذلك الألومنيوم والنحاس والألمونيوم والفولاذ المقاوم للصدأ، والمركبات، والبلاستيك لإنتاج الأجزاء لتلبية أي حاجة صناعية.

فريقنا من المهندسين ذوي الخبرة متاح دائمًا، مستعد لاستجابة CNC Machining لاستفساراتك. لديهم الخبرة والمعرفة اللازمة للتعامل مع جميع مخاوفك. أجزاء دقيقة مخصصة دقة: +\-0.01 مم، فضاء خاص: +\-0.005 مم.

نقدم خدمات OEM وODM الحد الأدنى لكمية الطلب هو وحدة واحدة يتم إرسال العروض خلال ثلاث ساعات يتطلب إنتاج العينة من 1 إلى 3 أيام يمكن أن يستغرق التسليم批量 من 7 إلى CNC Machining الإنتاج الشهري يتجاوز 300,000.

جميع الحقوق محفوظة © شركة شنتشن بيرفكت برسيزيون برودكتس المحدودة — سياسة الخصوصية—المدونة