المبنى 49، حديقة فومين الصناعية، قرية بينغهو، منطقة لونغغانغ

مغلق يوم الأحد

على أي حال، هل سبق أن تساءلت عن ما يدخل في صنع لعبة أو جهاز؟ إنه حقًا أمر مثير للاهتمام! كل هذه الأشياء الممتعة تبدأ كشيء يُسمى قالب. القوالب هي أدوات خاصة تصمم لإعطاء أشكال وأبعاد معينة للمواد، مثل البلاستيك أو المعدن. هذه العملية مهمة للغاية لأنها تضمن أن المنتجات التي نستخدمها يوميًا تعمل وتبدو بشكل مثالي. إحدى الشركات التي تتقن تصنيع هذه القوالب هي Swords Precision بالفعل!

في Swords Precision، نصمم ونبني قوالب مخصصة لجميع أنواع المنتجات الرائعة. يمكنهم إنشاء قوالب لأي شيء يمكنك تخيله! إذا استطعت تخيله، فهم يستطيعون تنفيذه. يتشاركون مع شركات مختلفة لإنشاء وتصنيع قوالب مخصصة لمنتجاتهم الخاصة. هذا يضمن أن تكون المنتجات التي تصنعها الشركات فريدة ومميزة - ولا تشبه ما قد تحصل عليه في المتاجر.

يأتي كل عميل بأفكار مختلفة، وكل منتج هو كيان منفصل. تعرف شركة Swords Precision هذا جيدًا. فهم أن عملاءهم قد يحتاجون إلى شيء بلون معين، مثل الأزرق الفاتح أو الأصفر المشمس. أما بالنسبة لآخرين، فيجب أن يكون حجم المنتج أو شكله معينًا ليتناسب مع خططهم. في أي حال، هم مستعدون لتوفير النماذج المثالية التي تلبي طلبك الخاص كما هو مطلوب. تُعتبر قوالبهم المخصصة المناسبة تمامًا، وهي مصممة من خلال تعاون دقيق مع العملاء. يضمن هذا التعاون أن كل شيء يتم تصنيعه وفقًا لتوقعات العملاء.

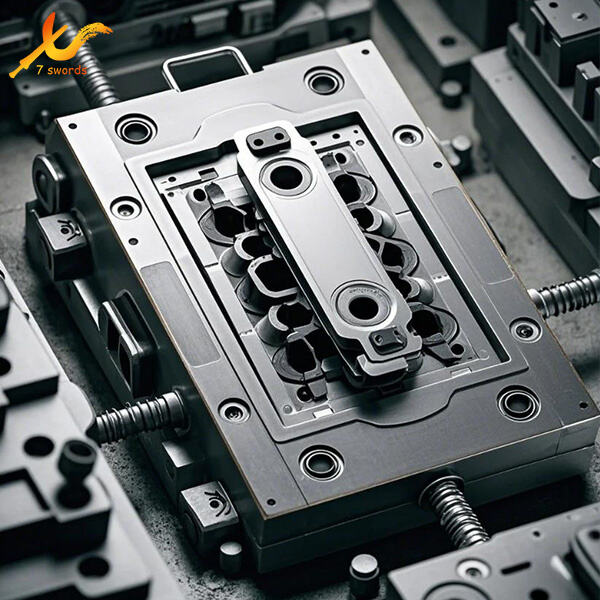

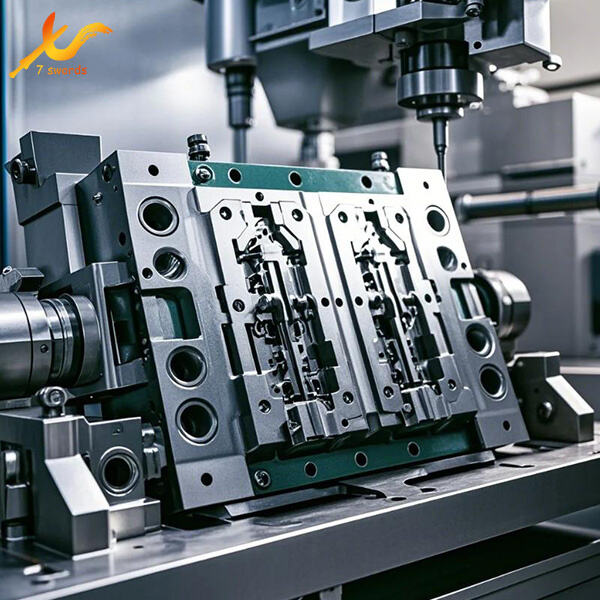

إنشاء قوالب مخصصة ليس إنجازاً يتحقق بين عشية وضحاها، ويحتاج إلى الكثير من المهارة والوقت والمعرفة. بعض أفضل المهندسين والمصممين في صناعة القوالب لدى Swords Precision يلعبون دوراً محورياً في تصميم وبناء هذه القوالب الخاصة. تبدأ العملية برسم القالب باستخدام برامج كمبيوتر متقدمة تتيح للفريق رؤية شكل القالب النهائي.

بعد إعداد التصميم، يتم تصنيع القالب لتلبية المتطلبات الخاصة بالمنتج. وبعد اكتمال القالب، يتم اختباره بصرامة لضمان الأداء الأمثل للقالب. إذا تم اكتشاف أي مشاكل، يعود المهندسون إلى نقطة البداية لمعالجتها. هذا过程 يساعد في ضمان أعلى جودة ممكنة للمنتج النهائي الذي يتم إنتاجه باستخدام القالب.

إحدى أفضل الأشياء في وجود قالب مخصص هو أنه يمكّنك من إتمام منتجك. يمكنك تعديل المنتج، تحسينه حتى تتأكد من أنه يشبه ما ترغب في تقديمه. في Swords Precision، يعملون عن كثب مع عملائهم لمساعدتهم على تحسين تصميم منتجاتهم. وهذا يسمح لهم بالتجربة مع مختلف الخيارات والأفكار التصميمية حتى يصلوا إلى الأنسب. هناك مجموعة واسعة من القوالب المخصصة المتاحة في السوق والتي تقدمها الشركات، مما يضمن أن تكون المنتجات التي يصنعها عملاؤهم منتجات فريدة تستهدف بشكل خاص الأشخاص الذين يريدون جذبهم إلى العملية.

يمكن أن يكون أكبر ميزة لاستخدام قالب مخصص لأجزاء السيليكون الخاصة بك هو أنه يضمن جودة مستقرة أثناء الإنتاج. يتم إنتاج المنتج بنفس المواصفات بفضل القالب. هذا يعني أن المنتجات متجانسة - الحجم أو الشكل أو اللون ليس عامل تميز ظاهر بين منتج وآخر. بالإضافة إلى ذلك، يشير ذلك إلى أن نفس مستوى الجودة يدخل في صنع كل منتج في كل مرة. هذه الطبيعة الثابتة هي أمر حاسم للشركات التي تسعى لتطوير قاعدة عملاء مخلصة. يثق العملاء بأنهم سيحصلون على نفس الجودة التي اشتروها في المرة السابقة.

جميع الحقوق محفوظة © شركة شنتشن بيرفكت برسيزيون برودكتس المحدودة — سياسة الخصوصية—المدونة