المبنى 49، حديقة فومين الصناعية، قرية بينغهو، منطقة لونغغانغ

مغلق يوم الأحد

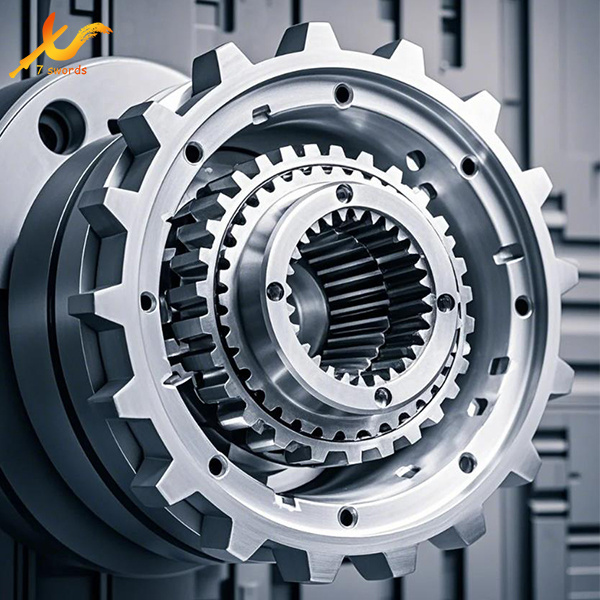

ماذا يحدث إذا سألتَ آلة؟ هناك آلات في كل مكان حولنا، وداخل الآلات ستكون هناك تروس تجعلها تعمل! التروس - الترس هو عنصر مهم يُستخدم في الآلات حيث يساعد الآلة على التشغيل وتغيير السرعة أيضًا. ومع ذلك، فإن صنع التروس عمل صعب يتطلب آلات خاصة ومهارات محددة.

تختص Swords Precision بتصنيع التروس باستخدام تقنية قطع خاصة. وبهذا نعني قطع التروس ببطء ودقة شديدة إلى أجزاء صغيرة جدًا. هذه الدقة العالية تسمح للترس بالانخماص مع بعضه البعض بشكل مثالي، مما يعني أن هذه الآلات يمكنها العمل بسلاسة دون أي توقف. التروس المصنوعة بدقة تدعم آلات تعمل بشكل أفضل وستظل قيد التشغيل لفترة طويلة.

تصميم العجلات على الحواسيب هو المرحلة الأولى نحو التصنيع. نحدد كيف يبدو شكل العجلة ونخطط لكيفية عملها. بمجرد اكتمال التصميم، نقوم بتنفيذه على جهاز يُسمى آلة تشكيل العجلات. يتم قطع القطعة المعدنية باستخدام هذا الجهاز لتشكيل العجلة كما هو موضح. يستخدم أداة تُسمى hob والتي تدور بسرعة عالية وتقطع الأسنان على العجلة. هذه الأسنان هي الأجزاء التي تتفاعل مع العجلات الأخرى.

آلة CNC واحدة من الآلات الأساسية التي لدينا في ورشتنا. CNC تعني التحكم الرقمي بالحاسوب. بهذا نعني أن برنامجًا حاسوبيًا يوجه الجهاز عما يجب فعله، مما يتيح لنا تصنيع العجلات بدقة كبيرة. تساعدنا هذه الآلات على تصنيع العجلات بتسامحات دقيقة للغاية، مما يضمن استمراريتها في العمل بشكل صحيح.

نستخدم أيضًا أداة تُعرف باسم Gear Shaper. ثاني أدواتها الميكانيكية المفيدة هي جهاز Gear Shaper الذي يمكّننا من إنشاء عجلات تروس ذات أشكال غير قياسية، مثل التروس الحلزونية. التروس الحلزونية تستخدم أسنانًا مائلة بدلاً من الأسنان المستقيمة. هذا الشكل غير الاعتيادي يعني أنها تتداخل بشكل جيد وتعمل بصمت - وهو أمر حاسم في بعض الآلات.

Swords Precision هي شركة تصنع التروس باستخدام آلات CNC الحديثة. باستخدام هذه الآلات الحديثة لإنتاج مفاهيم وتصاميم كانت ستكون صعبة للغاية أو شبه مستحيلة الصنع يدويًا. ليس هذا فقط يوفر الوقت، ولكن يمكننا أيضًا تصنيع التروس وفقًا لمتطلبات محددة لعملائنا.

مع تقنية CNC، يمكننا تصنيع التروس بشكل أسرع وأكثر اتساقًا. وبالتالي نحن قادرون على الاستجابة لاحتياجات عالية من الصناعات الحديثة. كما أننا قادرون على تصنيع كميات أقل من التروس عند الحاجة، مما يجعلنا مثاليين للأجهزة المخصصة والمفاهيم الجديدة التي قد يأتي بها عملاؤنا.

جميع الحقوق محفوظة © شركة شنتشن بيرفكت برسيزيون برودكتس المحدودة — سياسة الخصوصية—المدونة