المبنى 49، حديقة فومين الصناعية، قرية بينغهو، منطقة لونغغانغ

مغلق يوم الأحد

سيوفز بريسيزيون هي شركة جديدة تطور مجموعة واسعة من المنتجات. تطبق عملية تسميها الطباعة الصناعية ثلاثية الأبعاد. أي أنها لديها طابعة ثلاثية الأبعاد تقوم ببناء الأشياء طبقة واحدة تلو الأخرى. مقارنةً مع العمليات التقليدية الأكثر شيوعًا، حيث يتم قطع أو ضغط الجسم من قطعة كبيرة من المادة. آلة صنع الجسم هي الطباعة ثلاثية الأبعاد، وهي عملية مثيرة للاهتمام لأنها تبني المنتج طبقة تلو الأخرى.

هناك العديد من المزايا لطباعة ثلاثية الأبعاد صناعية تتيح للعديد من الصناعات التطور منذ البداية!؟ يوجد هنا فائدة كبيرة - فهي تمكن الشركات من تصميم نماذج ذات تفاصيل دقيقة للغاية، والتي سيكون من الصعب تحقيقها، إن لم يكن مستحيلاً، باستخدام العمليات القديمة. وهذا يعني أنهم يمكن أن يكونوا أكثر ابتكارًا وإنشاء عروض متميزة.

الشخصنة هي ميزة أخرى حاسمة. التميز من خلال منتجات 1:1 (الطباعة ثلاثية الأبعاد) تمكن الشركات من تصنيع العناصر التي تلبي احتياجات الفرد. كما أنها تسمح لهم بإنتاج منتجات مخصصة تناسب المتطلبات المحددة للمستخدم، مما يجعل المنتجات أكثر وظيفية. على سبيل المثال، إطار دراجة مخصص يمكن أن يناسب الشخص بشكل جيد، مما يجعل القيادة أكثر راحة.

ربما واحدة من أكبر الفوائد المتعلقة بالطباعة ثلاثية الأبعاد هي أنها تقلل من النفايات. العديد من تقنيات التصنيع التقليدية تزيل كمية أكبر من المواد اللازمة، مما يؤدي إلى مستوى عالٍ من النفايات. ومع ذلك، باستخدام الطباعة ثلاثية الأبعاد، يمكن للشركات إنتاج ما يحتاجون إليه فقط. ليس هذا فقط يوفر المال، ولكنه يساعد أيضًا في حماية البيئة عن طريق تقليل النفايات.

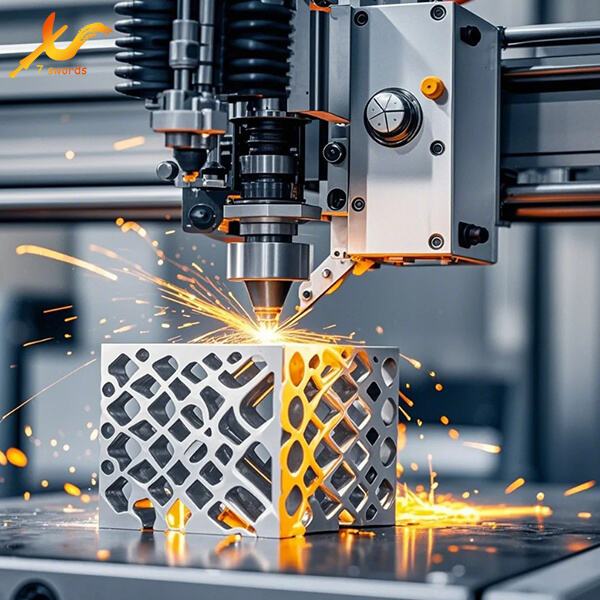

تستخدم شركة Swords Precision نوعًا من طباعة ثلاثية الأبعاد يُعرف باسم تشكيل الليزر الانتقائي. في هذه العملية، يقوم الليزر بذوبان مسحوق معدني ناعم ودمجه معًا لتشكيل جسم صلب. وهذا يسمح لهذه الطريقة بإنشاء أجزاء دقيقة ومعقدة بدرجة عالية من الدقة. تحتاج إلى هذه الدقة عند إنشاء قطع يجب أن تتناسب مع بعضها البعض بشكل جيد.

التطبيق الثالث لطباعة ثلاثية الأبعاد الصناعية هو في المجال الطبي. تتيح الطباعة ثلاثية الأبعاد للأطباء تصنيع زرائع مثالية التوافق للمرضى. وهذا يعني أنه بدلاً من استخدام الزرعات ذات الأحجام القياسية الواحد أو الاثنين التي قد لا تناسب على الإطلاق، يمكنهم تصنيع الزرعة خصيصًا لكل فرد. كما تُستخدم الطباعة ثلاثية الأبعاد أيضًا في إنشاء الأطراف الصناعية لأولئك الذين فقدوا عضوًا. يمكن تعديل مثل هذه الأطراف الصناعية لتتناسب بشكل أفضل مع الأفراد وأن تكون أكثر راحة.

يقلل من الهدر لأن الطباعة الصناعية ثلاثية الأبعاد تصنع فقط ما هو ضروري، مما ي消م على القضاء على الهدر وإنتاج المواد الزائدة. لا يوفر هذا للشركات الآلاف من التكاليف التشغيلية فحسب، بل يسمح لها أيضًا بالعمل بطريقة أكثر استدامة. وهذا يمكّن الشركات من توفير تكاليف المواد، ويمكنها تخصيص هذه الموارد لتحسين منتجاتها لمصلحة عملائها.

جميع الحقوق محفوظة © شركة شنتشن بيرفكت برسيزيون برودكتس المحدودة — سياسة الخصوصية—المدونة