المبنى 49، حديقة فومين الصناعية، قرية بينغهو، منطقة لونغغانغ

مغلق يوم الأحد

لا عجب أن المليارديرات مثل جيف بيزوس وإيلون ماسك يقولون غالبًا إنه这只是 مسألة وقت حتى يستعمر البشر كوكب المريخ. إنه أمر مثير للإعجاب حقًا! معظم هذه المنتجات مصممة باستخدام عملية تُسمى تشكيل بالحقن. إذا كنت تقرأ هذا، فمن المحتمل أن لديك شيئًا مصنوعًا بطريقة التشكيل بالحقن في يدك - فقط انظر إليه. يتم استخدام أجزائه بشكل أساسي في السيارات والإلكترونيات ومعدات الطبية التي تساعد الجميع، ولكن كلها قد تُصنع من خلال عملية تشكيل البلاستيك بالحقن كما نفعل في سواردز بريسيزيون. في هذا المقال سنستكشف كيف يعمل تشكيل القوالب وأهميته.

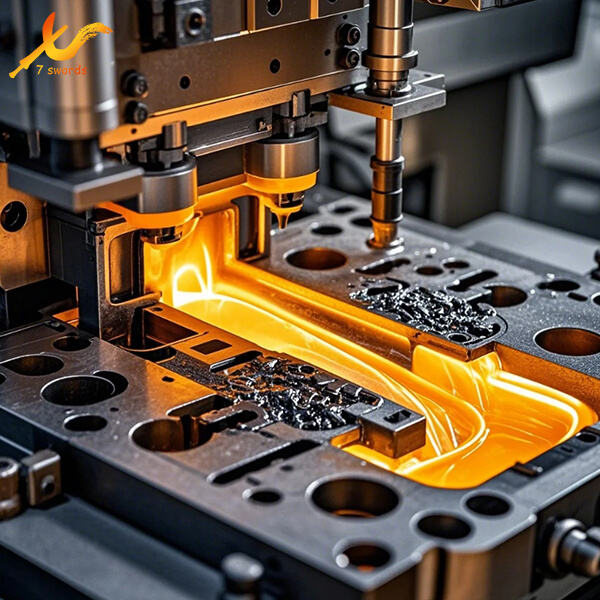

التشكيل بالحقن هو عملية يتم فيها وضع المواد المذابة في قوالب مما يسمح بإنشاء أجزاء مختلفة. القالب هو شكل محدد توضع فيه البلاستيك. إذن كيف يحدث كل هذا؟ لدينا قطع بلاستيكية صغيرة تُعرف بالحبيبات ونسكبها في حاوية كبيرة تُسمى الخزان. ثم نسخن الحبيبات، مما يجعلها ساخنة جدًا ويسبب لها الذوبان إلى سائل كثيف. عندما يذوب البلاستيك، ندخله إلى القالب. في النهاية، يبرد البلاستيك السائل ويتماسك على شكل القالب. يبدو الأمر بسيطًا ولكن ا相信ني يعمل بشكل رائع!

الجزء الأكثر تنظيماً في تشكيل الحقن هو القدرة على صنع عناصر ذات تنوع كبير في الشكل والحجم. باستخدام القوالب يمكننا تقريباً صنع أي شيء من أشكال بسيطة إلى تصاميم معقدة. على سبيل المثال، إذا أردنا تصنيع لعبة تشبه الديناصور. تتيح لنا عملية تشكيل الحقن إنتاج أجزاء متعددة الألوان والملمس أيضاً. وهذا هو السبب في أنك ترى العديد من الألعاب الزاهية في المتاجر، لأنها تُصنع باستخدام قوالب متنوعة ومواد بلاستيكية ملونة!

فوائد إضافية لعملية تشكيل الحقن هي إنتاج أجزاء دقيقة ومتسقة بشكل عالي التكرار. نحن نستخدم الحواسيب لدعم مرحلة تصميم القوالب. هذه الحواسيب تضمن إنشاء عدة قوالب لك، مما يضمن أن كل جزء يبدو بالضبط مثل سابقه. خاصة عندما يتعلق الأمر بالأجهزة الطبية، هذا أمر مهم جداً. على سبيل المثال، يجب أن يتم تصنيع الأدوات المساعدة للأطباء أو المرضى بنفس الطريقة من أجل السلامة والفعالية.

بما أن تشكيل بالحقن لا يتيح لنا فقط صنع أجزاء دقيقة، ولكن أيضًا يمنحنا التحكم فيما يتعلق بكمية البلاستيك التي نحقنها لكل قطعة، فهو الأسلوب المفضل لصنع مكونات السيارات. يوفر المال ويشجع على استخدام كمية أقل من البلاستيك. يمكننا أيضًا خلط مواد أخرى مع البلاستيك لتحسين قوته وصلابته. وهذا يوفر منتجًا نهائيًا أكثر استدامة وأطول عمرًا - وهو أمر حاسم في حالة اللعب والأدوات.

ومع ذلك، هناك العديد من المزايا لعملية تشكيل بالحقن. يمكنها إنتاج أجزاء ذات تعقيد عالٍ ودقة كبيرة وبتكلفة منخفضة وفي وقت قصير. مرة أخرى، إنها طريقة فعالة جدًا لأنها في الواقع تقلل من الهدر ولا تحتاج إلى كمية كبيرة من العمل الإضافي على الجزء. حسنًا، هناك بعض المزايا؛ لكن هناك أيضًا قضايا يجب مراعاتها. قد تكون تكلفة القوالب مرتفعة، ويجب تصميمها بدقة على سبيل المثال. يجب أن تكون القالب مثالية، أو قد لا يتدفق البلاستيك بشكل صحيح وستظهر الأخطاء في الأجزاء النهائية.

لإيجاز الأمر، تشكيل بالحقن هو عملية أساسية للغاية وتأثيرها واضح في معظم المنتجات التي نواجهها يوميًا. تستخدم Swords Precision تشكيل بالحقن لإنتاج أجزاء للمركبات والإلكترونيات والمعدات الطبية. يمكننا بهذه الطريقة تحقيق دقة أكبر ومعقدة في الأجزاء وتوفير المال وكذلك المواد.

جميع الحقوق محفوظة © شركة شنتشن بيرفكت برسيزيون برودكتس المحدودة — سياسة الخصوصية—المدونة