المبنى 49، حديقة فومين الصناعية، قرية بينغهو، منطقة لونغغانغ

مغلق يوم الأحد

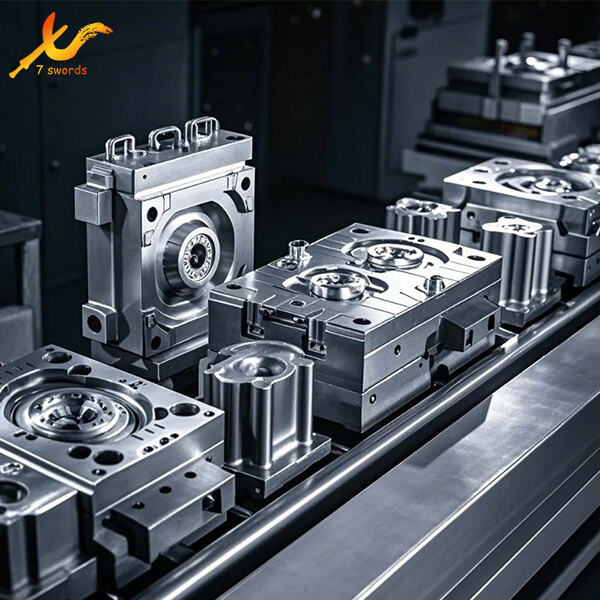

القوالب المعدنية هي أدوات مفيدة جدًا توفر لنا الدقة في صنع المنتجات. تُستخدم لتصنيع العناصر التي تكون موحدة الحجم والشكل. وهذا مهم جدًا لأنه يعني أن المنتجات تكون موحدة. النص التالي سيخبرك عن مزايا القوالب المعدنية تليها نظرة حول كيفية استخدامها في العمليات التصنيعية لمساعدتنا في تقديم منتجات ذات جودة عالية لمختلف الصناعات.

القوالب المعدنية هي أدوات تصنيع بدقة عالية حرفياً، والتي من خلال معالجة أجزاء معدنية، يمكنها إنتاج أشياء ضمن نطاق حجم قريب جداً. القالب المعدني يضمن أن كل منتج يكون متطابقًا. ومعنى ذلك أنه إذا قمت بشراء منتج تم صنعه باستخدام قالب معدني، فإنه سيبدو ويشعربالمثل تمامًا مثل أي من المنتجات الأخرى المصنعة من نفس القالب. تُصنع القوالب باستخدام المعدن، وهو مادة شديدة الصلابة. يمكن للقالب المعدني إنتاج أنواع مختلفة من المنتجات، من أصغر برغي وأزرار إلى أجزاء كبيرة من السيارة وحتى الأثاث الكبير الآخر.

من الضروري possessing القوالب المعدنية المناسبة للحقن البلاستيكي لإنشاء أي منتجات جيدة. فهي تساعد في التأكد من أن كل منتج يطابق في المظهر والملمس، وهو عامل مهم لأي شركة تحتاج إلى تقديم نفس المنتجات لعملائها. عندما يشتري العميل منتجًا ويعجب به، يريد التأكد من أن التالي الذي سيشتريه سيكون بنفس الجودة.

لدى العديد من الأنواع المختلفة من الشركات قوالب معدنية. على سبيل المثال، فإنها تساعد الصناعة في تصنيع أجزاء للمحركات ومكونات مختلفة من السيارات. تُستخدم في الإلكترونيات، حيث تصنع القوالب المعدنية أجزاءً لمجالس الكمبيوتر والأجهزة. كما أنها تساعد في إنتاج المعدات الطبية التي تنقذ الحياة لقطاع الرعاية الصحية.

يمكنك اختيار أنواع مختلفة من المعادن لصنع هذه القوالب، مثل الصلب، الألمنيوم والنحاس. كل معدن يأتي بخصائص فريدة تجعله مناسبًا لتطبيقات مختلفة. على سبيل المثال، الصلب هو قوي جدًا ويُعتبر مثاليًا عند إنشاء قالب سيتم استخدامه لتشكيل منتجات أثقل. الألمنيوم يمكن أن يكون أخف وزنًا (إذا كان الوزن عاملًا مهمًا) والنحاس، بالطبع، واحد من أفضل موصلات الحرارة والكهرباء.

مع تقديم العديد من الطرق والتكنولوجيات الجديدة، أصبحت القوالب المعدنية أسهل وأكثر كفاءة من حيث التكلفة في الأوقات الأخيرة. في السنوات الأخيرة، تمكنت الشركات المصنعة من إنتاج قوالب ذات ميزات وأشكال مثيرة كانت صعبة الصنع سابقًا بسبب التقدم التكنولوجي. هذا فتح الباب لإنشاء منتجات واعية بناءً على ما يعتز به العملاء.

تشمل الطرق الشائعة التي تُستخدم مع القوالب المعدنية الطوابع، التشكيل والصب. كل طريقة لها مزاياها الخاصة وتُستخدم بناءً على نوع المنتج. على سبيل المثال، الطابع فعال في إنتاج أجزاء صغيرة دقيقة يجب أن تتداخل مع بعضها البعض بينما يتفوق الصب في الأجزاء الأكبر والأكثر تعقيدًا والتي لا تحتاج إلى الكثير من التفاصيل.

جميع الحقوق محفوظة © شركة شنتشن بيرفكت برسيزيون برودكتس المحدودة — سياسة الخصوصية—المدونة