المبنى 49، حديقة فومين الصناعية، قرية بينغهو، منطقة لونغغانغ

مغلق يوم الأحد

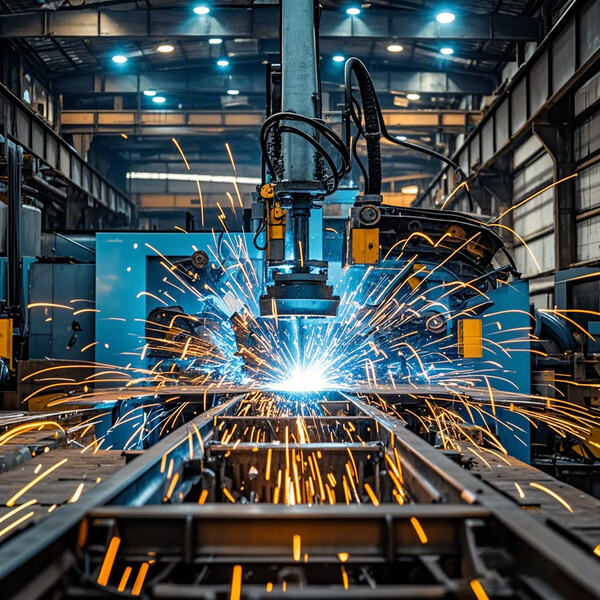

تصنيع المعادن هو شغفنا، دقة السيف. هذه هي عملية فريدة من نوعها حيث نقوم بتنقية المعدن الخام وتحويله إلى منتجات مفيدة يريدها الناس. يمكننا إنتاج مكونات الآلات، وتماثيل فنية جميلة، وأجزاء أساسية للسيارات والعديد من السلع الأخرى التي تسهل الحياة. التقطيع والثني واللحام هي بعض الخطوات الممتعة التي تشكل تصنيع المعادن. نحن نصقل ونحسن كل قطعة لإنشاء جزء خالد من الجمال له دور مهم — مما يجعله لاعبًا أساسيًا في العديد من الصناعات.

أجزاء دقيقة لصناعات الطيران والفضاء تستخدم عددًا من العمليات، بما في ذلك القص والثني واللحام، كما ناقشنا سابقًا. وكل واحدة من هذه الخطوات ضرورية لأنها تحوّل المعدن الخام إلى الشكل والحجم المناسبين لما نحتاجه. الخطوة الأولى، وهي القص، يمكن تنفيذها باستخدام أدوات مختلفة. على سبيل المثال، يمكن استخدام المناشير، وآلات القطع بالبلازما والليزر لتقسيم المعدن إلى قطع. يأتي الثني بعد القص وبعد الانتهاء منه. يتم إنجاز هذا الجزء باستخدام ماكينة ثني ذات سرير مستوٍ. الضغط الناتج عن آلة الثني يجبر المعدن على الانحناء إلى الشكل المرغوب فيه. وأخيرًا، اللحام هو الخطوة الأخيرة. تتضمن هذه العملية تطبيق الحرارة على أجزاء المعدن للذوبان وإعادة دمجه معًا. جميع هذه التقنيات تتطلب انتباهًا شديدًا ودقة لضمان أن النتيجة النهائية صحيحة ومناسبة لعملائنا.

الدقة واحدة من أكثر الجوانب أهمية في صناعة المعادن. لذلك، عندما نقوم بالقطع أو ثني أو لحام المواد، يجب أن يتم كل شيء بعناية شديدة. إذا تجاهلنا ذلك، قد لا يقوم المنتج النهائي بما هو مفترض أن يفعله. هذا المستوى من الدقة يتطلب من صانعي المعادن امتلاك حاسة دقيقة للتفاصيل. كما يتطلب معرفة وثيقة بالمواد المستخدمة. التأكد من أن قطع المعادن تناسب بشكل صحيح وتؤدي عملها كما يجب يستغرق الكثير من الجهد والوقت والمهارة لضمان أن كل شيء يتم بطريقة صحيحة. وإذا تم كل شيء بالشكل الصحيح، فإنه يصبح منتجاً قوياً وموثوقاً يؤدي وظيفته بشكل جيد.

تُستخدم عملية صناعة المعادن في مختلف القطاعات والحقول، مثل البناء، والسيارات (السيارة)، والبحري (القوارب)، والزراعة (التربية). في قطاع البناء، يمكن لصناعة المعادن إنتاج مكونات أساسية مثل هيكل المبنى بالكامل وأبواب الحديد وسواتر السلامة. إنتاج العديد من أجزاء السيارات مثل دعائم المحرك، وأجسام السيارات، وإطارات الأبواب في صناعة السيارات. ومن بين المجالات الأخرى، تُنتج صناعة المعادن في الزراعة خزانات الحبوب، والمستودعات، ومعدات التخزين الأخرى التي تدعم المزارعين. لهذا السبب تعتبر صناعة المعادن مجالًا مثيرًا للغاية؛ حيث لا حدود لإمكانياتها فيما يتعلق باستخداماتها.

على مر السنين، أدت العديد من التطورات التكنولوجية إلى تغيير كبير في مجال تصنيع المعادن. في الوقت الحاضر، يستخدم معظم مصنعي المعادن برنامجًا حاسوبيًا يُعرف بـ CAD أو تصميم المساعد الحاسوبي. يساعدنا هذا البرنامج في تطوير تصاميم معقدة جدًا ومت错ّقة سيكون من المستحيل تقريبًا إنشاؤها يدويًا. علاوة على ذلك، فإن عددًا متزايدًا من المنظمات أصبحت أكثر وعيًا بالقضايا البيئية وتبحث عن مواد وعمليات صديقة للبيئة تُستخدم في تصنيع المعادن. هذا السعي نحو الاستدامة يدفع الصناعة في اتجاه إيجابي. وبالتالي، فهي صناعة تتغير باستمرار مما يجعل العمل مع المعادن مثيرًا.

جميع الحقوق محفوظة © شركة شنتشن بيرفكت برسيزيون برودكتس المحدودة — سياسة الخصوصية—المدونة