المبنى 49، حديقة فومين الصناعية، قرية بينغهو، منطقة لونغغانغ

مغلق يوم الأحد

تتمتع Swords Precision بخبرة واسعة في إنتاج مجموعة متنوعة من الأشياء من الفولاذ والألومنيوم. يُطلق على عملية صنع العناصر من المعدن اسم "إنتاج المعادن الورقية". هذه عملية حيوية حيث نصنع فيها مكونات معدنية مختلفة. هناك عدد من الأمور التي يجب أن نأخذها في الاعتبار عند صب الأجسام المعدنية لضمان استقرارها وللحصول على مظهر جيد.

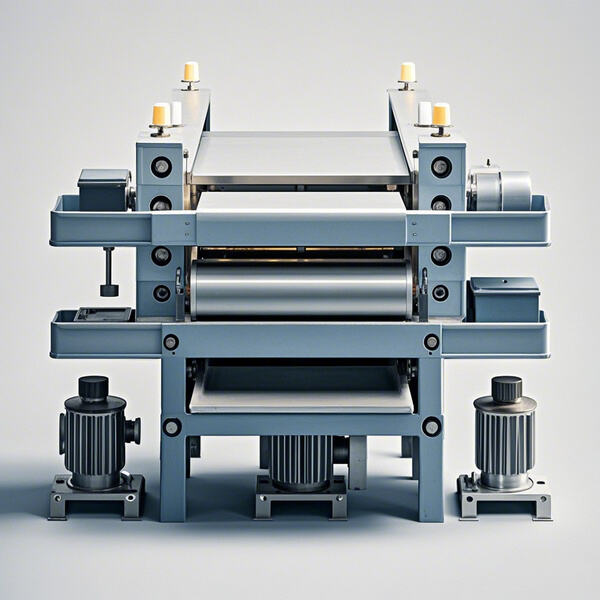

لدى Swords Precision عدد من الأدوات الخاصة المكرسة لتحقيق الإمكانات الجمالية الموجودة (والمتجاوزة) في أجزاء المعدن. الخطوة الأولى: يقومون بإنشاء الجزء المعدني باستخدام برامج كمبيوتر متقدمة. لذلك يمكنهم تصور الجزء قبل قطع أي معدن فعلي. بمجرد إنشاء التصميم، يعملون مع آلات قوية قادرة على قص وثني المعدن إلى أشكال محددة. تضمن Swords Precision تفاصيل الحجم والشكل الدقيق لأجزاء المعدن. وبالتالي، يساعد ذلك في التأكد من أن التسليم سيؤدي وظيفته بشكل صحيح بالإضافة إلى تحقيق متطلبات العملاء.

إحدى أهم الأشياء التي تقوم بها Swords Precision هي التصنيع المخصص. وهذا يعني إنشاء شيء فريد لعمل معين أو عميل معين. أحد الفوائد التي تقدمها الأجزاء المصنعة ميكانيكيًا بواسطة Swords Precision هو أنها يمكن أن تكون مصممة خصيصًا لتلبية متطلبات العميل. أحد أكبر العوامل التي تجعل الحصول على منتج مخصص مريحًا هو أن المواد المخصصة تؤدي وظائف أفضل وكذلك تصاميم. مثل الأقواس وحتى الآلات الكبيرة المستخدمة لتصنيع المنتجات في المصانع. يتيح هذا التصنيع المخصص لشركة Swords Precision جعل منتجاتها مفيدة وعملية لعملائها.

تُصنِع Swords Precision منتجات معدنية مميزة بقوتها الشديدة. تصنع منتجاتها لتتحمل لفترات طويلة، حتى في الظروف الجوية القاسية. المعدن الذي يختارونه مصمم لتحمل الرياح العالية والبرد والأمطار. بالإضافة إلى استخدام المعادن الثقيلة، تضيف Swords Precision طبقات إضافية لتوفير حماية وزيادة القوة. هذه الطبقات تشكل طبقة واقية تساعد في مقاومة الصدأ، وهو أمر بالغ الأهمية للحفاظ على المظهر الجمالي ومتانة المعدن نفسه.

تقوم Swords Precision باختبارات مستمرة بهدف تحسين عملية صنع المعادن. لا يمانعون في استخدام مواد جديدة، ولا يمانعون في استخدام أدوات مختلفة طالما أنها تساعد في العمل بسرعة مع منتج قوي. بدلاً من قطع قطعة معدنية باستخدام المنشار، يمكنهم قطعها باستخدام الليزر. وهذا يعني أنه يمكن توفير الوقت والحصول على قطع أدق وأكثر نعومة على المعدن. بالإضافة إلى ذلك، تستخدم Swords Precision الروبوتات لمساعدتها في عملية التصنيع. حيث أن هذه الروبوتات قادرة على العمل بشكل أسرع من البشر وسترتكب أيضًا أخطاء أقل. كما أن استخدام الروبوتات يضمن إنتاج العناصر المعدنية بدرجة أعلى من الدقة.

لدى سوورز بريسيزيون ترابط وثيق بين الدقة وضمان الجودة. يتم فحص كل مكون معدني يصنعونه بشكل شامل. وهذا يعني التأكد من أن كل جزء هو بالحجم والشكل الدقيقين. كما يقومون أيضًا باختبار قوة المعدن ومعرفة إذا كان سيتكسر بسهولة أم لا. لدى سوورز بريسيزيون آلات خاصة للكشف عن التفاصيل الصغيرة جدًا التي قد يفوتها الإنسان. كما لديهم العديد من العمال المهرة لفحص أجزاء المعدن للتأكد من كونها مثالية للاستخدام وتتوافق مع المعايير المطلوبة للجودة في كل بوصة منها. هذا الفحص الدقيق ضروري لأنه يضمن أن جميع منتجاتهم تعمل بشكل جيد وهي آمنة للاستخدام.

جميع الحقوق محفوظة © شركة شنتشن بيرفكت برسيزيون برودكتس المحدودة — سياسة الخصوصية—المدونة