المبنى 49، حديقة فومين الصناعية، قرية بينغهو، منطقة لونغغانغ

مغلق يوم الأحد

تشكيل البلاستيك بالحقن هو موضوع مثير ومهم للغاية! لنفترض أنك لم ترَ أو تسمع عن البلاستيك من قبل. البلاستيك هو مادة فريدة يمكن إذابتها وتشكيلها إلى مجموعة متنوعة من المنتجات، تمامًا كما تشكل الطين. نحن ننتج العديد من المنتجات التي تلعب بها، أو تستعملها، أو تستهلكها من خلال طرق مثل التشكيل بالحقن (فكر في الألعاب، قطع السيارات، التغليف الذي يحتوي على طعامك).

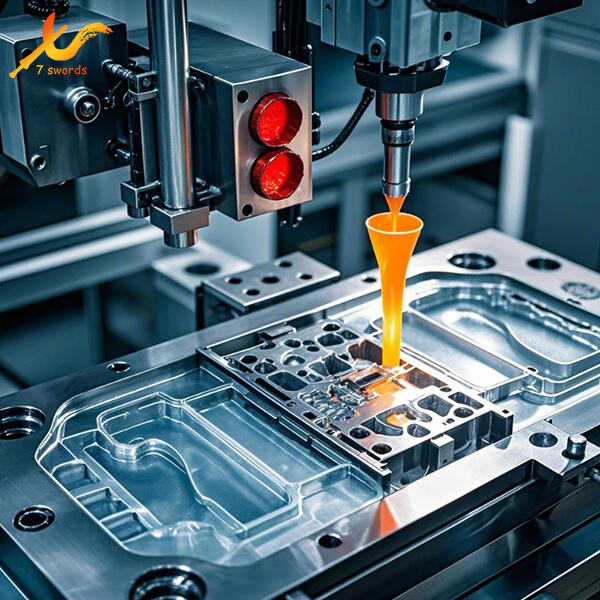

التشكيل بالحقن — حسنًا، كيف يعمل هذا؟ إنه عملية رائعة! يتم إذابة البلاستيك أولاً إلى سائل لزج جدًا. بعد ذلك، يتم ضخ هذا البلاستيك المذاب داخل قالب. القالب هو نوع من الصندوق الذي يحمل شكل القطعة المرغوبة. تخيل مقص الكوكيز! بعد أن يذوب البلاستيك داخل القالب,则 يبرد ويتماسك. بمجرد التبريد، يمكن إزالة الشكل الجديد من القالب. تُستخدم هذه العملية في صناعة العديد من الأدوات المنزلية التي تراها وتستخدمها يوميًا — على سبيل المثال، فرش الأسنان، الأكواب وغطاءات الزجاجات!

إذن، دعونا الآن نناقش أنواع البلاستيك التي يمكن استخدامها في القالب بالحقن. هناك أنواع متعددة، ولكل نوع خصائص فريدة. من الأنواع الشائعة المستخدمة تشمل البوليبروبيلين، البوليثيلين، البولي كربونات و ABS. جميع هذه الأنواع لديها ميزاتها وعيوبها. لذلك يجب أخذ سعر البلاستيك، قوته ومرونته بعين الاعتبار عند اختيار النوع المناسب لمشروعك. بهذه الطريقة، يمكنك اختيار البلاستيك الأمثل لما تحتاج إلى إنشائه.

تصنيع القوالب بالحقن ليس دائمًا أمرًا سهلًا. على سبيل المثال، أحد المشكلات الشائعة هو عندما لا يملأ البلاستيك بعد الذوبان القالب بشكل كامل. يمكن أن يؤدي هذا إلى نقاط ضعف أو حتى تشوه المنتج النهائي. يمكن حل هذه المشكلة عن طريق تعديل القالب لضمان تدفق البلاستيك بشكل صحيح، أو بتعديل درجة حرارة وضغط البلاستيك. مشكلة أخرى قد تحدث هي تبريد غير طبيعي سريع للبلاستيك. إذا حدث ذلك، يمكن أن ينتهي المنتج النهائي مع شقوق أو يصبح منحنيًا. الحل لهذه المشكلة هو تبريد القالب بمعدل أبطأ أو اختيار نوع آخر من البلاستيك ليكون أكثر ملاءمة.

الكفاءة وتقليل الهدر تُعد من أهم الأولويات عندما نتحدث عن تشكيل بالحقن. في رأيي، أن تكون كفؤاً يعني تحقيق أقصى استفادة من الوقت والمصادر لإنتاج منتجات أفضل. استخدام الروبوتات/الآلات أثناء تشكيل الحقن هو أحد الطرق لزيادة الكفاءة. يمكن أن يسرع هذا الأمور بشكل كبير، مما يوفر الكثير من الوقت. ومن الأمور المهمة بنفس القدر التعامل مع النفايات. في حال بقاء بعض البلاستيك بعد تصنيع المنتج، يمكن إعادة استخدامه أو تدويره. لا يقتصر الأمر على توفير المال فقط، بل يساعد أيضاً في إنقاذ الكوكب بتقليل التلوث والنفايات.

موضوع ساخن عند مناقشة البلاستيك هو الاستدامة. يستغرق تحلل وتفتت النفايات البلاستيكية مئات، بل آلاف السنين في الطبيعة، مما يسبب التلوث الذي يؤثر على الحيوانات والنباتات على حد سواء. تعتبر البلاستيكات القابلة للتحلل الحيوي بديلاً أفضل لهذه المشكلة. يتم استخراج البيوبلاستيك من مصادر طبيعية، لذلك فهو قابل للتحلل السهل وغير سام للبيئة. البلاستيك المعاد تدويره — حل آخر رائع هو البلاستيك البديل المصنوع من مواد بلاستيكية مستعملة مسبقاً. يمكن أن يساعد التدوير في تقليل النفايات البلاستيكية التي تنتهي في مكبات النفايات.

تخصيص التشكيل بالحقن باستخدام البلاستيك هو أحد العمليات التي نتميز بها في Swords Precision. لدينا أعضاء فريق مخصصون لتقديم المساعدة في اختيار النوع المناسب من البلاستيك وحل التحديات الأخرى خلال مشروعك. نركز على الكفاءة وتقليل الهدر في كل خطوة من العملية. عادةً ما نقدم حلول بلاستيك مستدامة للتشكيل بالحقن. لذلك، إذا كنت ترغب في التواصل معنا لمعرفة كيف يمكننا مساعدتك في مشروعك، تواصل معنا!

جميع الحقوق محفوظة © شركة شنتشن بيرفكت برسيزيون برودكتس المحدودة — سياسة الخصوصية—المدونة