المبنى 49، حديقة فومين الصناعية، قرية بينغهو، منطقة لونغغانغ

مغلق يوم الأحد

هل سبق وأن تساءلت عن كيفية تحول الفكرة إلى شيء ملموس؟ ليس ذلك سحرًا، بل يُسمى هذا السرعة بـ"النمذجة السريعة"! إنها طريقة فريدة تستخدمها الشركات لتحويل أفكارها إلى منتجات ملموسة بشكل أسرع بكثير من طرق التصنيع التقليدية، وهي النمذجة السريعة. هذه الطريقة مفيدة جدًا لإنشاء نماذج أولية أو نماذج لمنتجات. يمكن اختبار هذه النماذج وتعديلها قبل الإنتاج الضخم. وهذا يتيح للشركات رؤية كيفية عمل منتجاتها وكيفية تعديلها لتحسين أدائها.

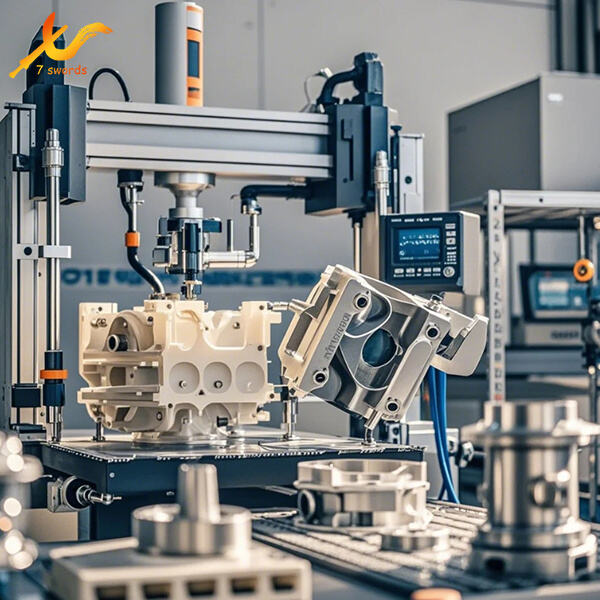

سwords Precision هي إحدى الشركات التي تركز على النماذج الأولية السريعة. يستخدمون أدوات رائعة مثل الطابعات ثلاثية الأبعاد لإنشاء التصاميم بسرعة فائقة وفورًا. هذا يسمح للشركات باختبار وتكرار منتجاتها بسرعة، مما يمكن أن يوفر وقتًا وتكلفة كبيرة. بدلاً من الانتظار لأشهر طويلة لمعرفة ما إذا كانت الفكرة تعمل، يمكنهم الحصول على هذه المعلومات تقريبًا فورًا. وهذا أمر بالغ الأهمية بالنسبة للشركات لأنه يؤدي إلى تكرار أسرع في تحسين منتجها أو ميزة.

عندما تحصل الشركات على فكرة جديدة، فإنها تريد رؤيتها في الحياة الواقعية فورًا. هنا تتدخل تقنية النماذج الأولية السريعة من Swords Precision لإنقاذ الموقف! وهي مثالية أيضًا لتصميم أنواع مختلفة من المنتجات الجديدة، من أجهزة طبية تساعد الأطباء، إلى مكونات هيكل الطائرات التي يمكنها الطيران عاليًا في السماء، إلى ألعاب الهواتف أو السلع المنزلية التي نستخدمها يوميًا. خلال هذا العملية، يمكن للشركات تحويل أفكارها المذهلة إلى أشياء عملية وقابلة للاستخدام في وقت قصير جدًا.

الإبداع أمر حاسم للتنمية التنظيمية لأن الاكتشاف يخلق شركة أكبر من المتوسط. بالنسبة للنماذج الأولية السريعة، يمكن للشركات التكرار بسرعة على الأفكار الجديدة وتحسينها، مما يعني منتجات ذات جودة أعلى يحبها العملاء. عندما تكون الشركات قادرة على تنفيذ التغييرات بسرعة، يمكنها تحسين منتجاتها وجعلها أكثر سهولة في الاستخدام. وهذا رائع للجميع!

تساعد النماذج الأولية السريعة الشركات على تحديد المشكلات في وقت مبكر ومعالجتها بسرعة. وهذا يُبسّط عملية تطوير المنتج بأكملها. كلما تمكنت الشركة من تحديد المشكلة في أقرب وقت ممكن قبل إنتاج كميات كبيرة من المنتج، قلّت هدر المواد والمصروفات المالية. كما يعني ذلك أن المنتج يمكن تسليمه بشكل أسرع، مما يمنح الشركة ميزة واضحة على منافسيها. شركة قادرة على تصنيع المنتج بسرعة يمكنها جذب المزيد من المستخدمين وتحقيق سمعة أفضل في السوق.

في الماضي، قد يستغرق إنشاء نماذج أولية ذات جودة عالية إلى الأبد؛ ولكن مع Swords Precision والتكنولوجيا المتقدمة التي تمتلكها، يمكن القيام بذلك في وقت قصير للغاية لأن لديهم الأشخاص الذين يمكنهم المساعدة. عملية إنشاء النماذج الخاصة بهم تتيح إنشاء نماذج أولية سريعة يمكن أن تكون مشابهة جدًا للتصميم الحقيقي. هذا يعني أن الشركات يمكنها معرفة كيف سيبدو منتجها وكيف سيعمل قبل إنشاء مئات أو آلاف الوحدات منه.

لهذا السبب تعتبر النماذج الأولية العليا أمرًا حيويًا للشركات، حيث تمكنها من اتخاذ قرارات منتجات مدروسة. ستجربون هذه النماذج في سيناريوهات واقعية لتحديد ما إذا كانت تعمل بشكل جيد، وجمع البيانات لتحسين المنتج قبل التصنيع. هذه الاختبارات غنية بالمعلومات جدًا لأنها يمكن أن تشير إلى وجود مشكلات تحتاج إلى معالجة.

نقدم مجموعة واسعة من خدمات إنتاج النماذج الأولية السريعة، بما في ذلك 3 محاور و4 محاور وحتى 6 محاور. نوفر مجموعة من القدرات التصنيعية التي تشمل التدوير، الحفر، الطحن، وال EDM، الطباعة ثلاثية الأبعاد. نعمل مع العديد من المواد المختلفة مثل النحاس، البرونز، الألمنيوم، الصلب، الصلب المقاوم للصدأ، البلاستيك والمركبات.

فريق الهندسة الاحترافي لشركات النماذج الأولية السريعة دائم الحركة، وينتظر للرد بسرعة على استفساراتك. هم مهرة للغاية ولديهم الخبرة اللازمة لمعالجة مخاوفك. الأجزاء المخصصة بدقة تسامح عالية: + / -0.01 مم، المنطقة الخاصة: + / -0.005 مم.

نقدم خدمات OEM وODM الحد الأدنى لكميات الطلبات هو شركات النماذج الأولية السريعة يمكننا تقديم العروض السعرية خلال 3 ساعات إنتاج العينات يستغرق من يوم إلى ثلاثة أيام عمل التسليم批量 يستغرق بين 7 و14 يومًا سعتنا الإنتاجية الشهرية تتجاوز 300,000 قطعة

لدينا شهادة ISO9001، شركات النماذج الأولية السريعة، ISO45001، الطبية ISO13485، الطيران AS9100، السيارات IATF16949، يمكننا إنتاج الأجزاء الميكانيكية، أجزاء السيارات، الأجزاء الإلكترونية، أجزاء الطيران والفضاء، أجزاء الأجهزة الطبية، أجزاء معدات الاتصالات، أجزاء الطاقة الجديدة، وأجزاء البناء والمنتجات المنزلية.

جميع الحقوق محفوظة © شركة شنتشن بيرفكت برسيزيون برودكتس المحدودة — سياسة الخصوصية—المدونة