المبنى 49، حديقة فومين الصناعية، قرية بينغهو، منطقة لونغغانغ

مغلق يوم الأحد

تشكيل النماذج الأولية السريعة هو عملية تمكن الأفراد من الحصول على كميات صغيرة من المكونات البلاستيكية في وقت قصير جدًا. هذه العملية غيرت مشهد التصنيع وأتاحت للشركات مثل Swords Precision تصوّر وإنتاج منتجات جديدة بشكل أسرع من أي وقت مضى. إنها شبيهة بقوة خارقة للتصنيع.

ومع ذلك، في الأيام الحالية مع أجزاء دقيقة لصناعات الطيران والفضاء يمكن للشركات مثل Swords Precision تسليم نموذج خلال 3 أيام فقط! هذا تحسين كبير! هذا يسمح لهم بتجربة مجموعة كبيرة من التصاميم المختلفة والعمل عليها بشكل أسرع بكثير مما كان عليه الأمر سابقًا. يمكنهم اختبار فكرة فورًا بدلاً من الانتظار لفترة طويلة لمعرفة ما إذا كانت تعمل.

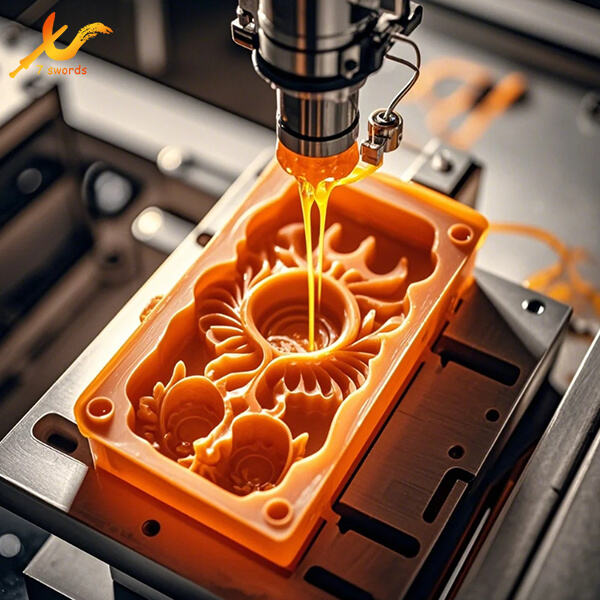

عندما يتم تشكيل القالب أخيرًا، تقوم آلة أخرى بملء هذا النموذج بالبلاستيك السائل. يكون هذا البلاستيك ساخنًا جدًا عند صبه داخل القالب، ثم يبرد ويتماسك. عندما يصبح البلاستيك صلبًا، يفتح القالب للوصول إلى الجزء المصنوع. يمكن تكرار هذه الدورة بأكملها عدة مرات، مما يسمح بإنتاج كميات كبيرة من الأجزاء بسرعة وتكلفة منخفضة. واحدة من أفضل الطرق لإنشاء الإنتاج الضخم دون إضاعة الوقت أو المال!

في هذه以及其他 طرق أولية، قطع CNC من الألومنيوم يغير شكل التصنيع في العصر الحديث. هذا لا يؤدي فقط إلى إنشاء منتجات جديدة، بل يقوم بذلك بشكل أسرع بكثير. يعني ذلك أنهم يستطيعون الاستجابة لاحتياجات العملاء تقريبًا فورًا. مع الزيادة السريعة في انتشار الألعاب، إذا ظهرت لعبة شهيرة، يمكن للشركات إنتاج المزيد بناءً عليها بسرعة.

التصنيع السريع للنماذج الأولية يتيح أيضًا للشركات التجريب مع تصاميم متعددة وتنفيذ التعديلات بناءً على ملاحظات المستخدمين. وبالتالي، يكون لدى المنتج النهائي فرصة أكبر للنجاح بسبب الملاحظات الحقيقية من العملاء التي تساهم في تحسينه أثناء العملية. وكأن لديك فريق اختبار لضمان أن كل شيء على ما يرام قبل إطلاق المنتج للبيع!

فوائد أخرى كبيرة للتصنيع السريع للنماذج الأولية هي إمكانية إنتاج أجزاء محدودة بتكلفة منخفضة جدًا. هذا له قيمة خاصة بالنسبة للشركات التي قد تحتاج إلى إنتاج مجموعة متنوعة من المكونات الفريدة لمنتج جديد. ليس عليهم إنتاج كميات ضخمة من المنتجات دفعة واحدة، بل يمكنهم إنشاء ما يحتاجون إليه فقط عند الضرورة.

يمكن لشركة Swords Precision إنتاج العديد من الأجزاء المختلفة للقطع التي تُصنع باستخدام تشكيل النماذج الأولية السريعة. هذا يمكّنهم من التجربة مع نهج مختلف وتعديل استراتيجيتهم استجابةً لملاحظات العملاء والحالات السوقية. وهذا يضمن لهم أن المنتج الذي يقدمونه يلبي احتياجات عملائهم.

جميع الحقوق محفوظة © شركة شنتشن بيرفكت برسيزيون برودكتس المحدودة — سياسة الخصوصية—المدونة