Когато търсите прецизните компоненти за критични проекти, всеки детайл е от значение. В PFT превръщаме сурови материали в CNC обработени части с висока производителност и хирургическа прецизност. Нашата тайна? Съчетание от най-новите технологии, безкомпромисно занаятство и мисъл, насочен към клиентите, което превръща сложни предизвикателства в плавни решения.

Защо производителите ни избират: Непреодолимото предимство

1. Современо производствено вооружение

Нашата мастерска функционира като симфония от глобално инженерно превъзходство:

-

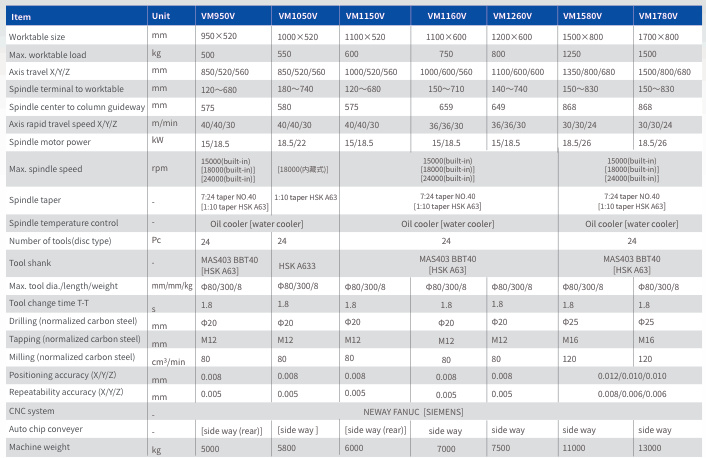

Мастерство в многоосова обработка : 5-осни CNC центрове като VM1780V (повторяемост 0,005мм, мощност на шпиндел 18,5кВт и N9-2513ATC с италиански шпиндели Hiteco с 24 000 об. мин., които обработват сложни геометрии в един setup.

-

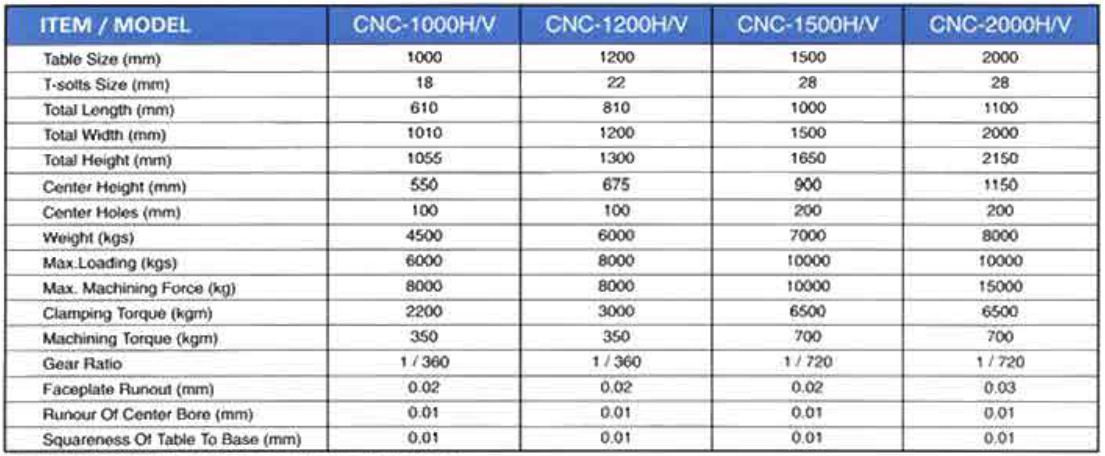

Висока точност с голяма капацитет машини като CNC-2000H/V поддържат тегло от 2,000кг, докато запазват толеранции ±0.03мм , идеални за авиационно и автомобилно производство.

2. Науката за съвършенството във всеки пресич

Не просто следваме процеси – ги проектираме:

-

Мachining с етапно управление : Строги грубо обработване → полуфинишно обработване → финишно обработване → леко финишно обработване протоколът гарантира безстресни повърхности (се постига Ra0.8μm ).

-

Материална Интелигенция : Реално време термично компенсация на всички врътелни оси предотвратява микродеформации по време на обработката на титан/алюминий.

-

"Култура Без Дефекти" : Всеки техник преминава през над 500 часа тренировка по GD&T преди да работи с производствени части.

3. Контрол на Качеството, Който Превишава Отраслите Стандарти

Вашата сигурност е нашата многослойна система за верификация:

-

Мониторинг По време на Процеса : Лазерни скенери и КММ (точност 0.5μm) провеждат непрекъснати размерни проверки по време на фрезирането .

-

Тraceabilitet на материали : Всяка билина получава цифрова паспорт, проследявана чрез блокчейн от източника до доставката.

-

Сертифицирано отличие : Сертифициран според ISO 9001:2023 с 0 големи клиентски жалби за 5 години – доказателство за нашата процесна честност.

4. Централен хаб за kompleтни решения

От прототип до масовно производство, ние покриваме целия ваши път:

| Фаза на обслужване |

Възможности |

Времетраене на изпълнение |

| Бързо проектиране на прототипи |

3D печат (метал/полимер), CNC тестови части |

48-72 часа |

| Производство с нисък обем |

50-10 000 бройки с пълен обратен връзок по DFM |

2-5 седмици |

| Производство с голям обем |

Дedicated производствени яйца (повече от 100k единици/месец) |

На база договор |

Пример: През миналия тримесечие доставихме 15 000 компонента за медицински имплантати с успех от първи проход 99,98%.

5. Партньорска поддръжка след продажбата

Забравете за „тicket-и за поддръжка“ – изживейте партньорство с инициатива:

-

Управление на жизнения цикъл : Съответства на GB/T 16784-2008 промышленни стандарти Z, включително дистанционна диагностика чрез IoT-омогнати машини.

-

Служби за градинарен отговор : Гарантирана техническа консултация в рамките на 4 часа за неотложни спирания на производството.

-

Непрекъснато подобрение : Безплатни годишни аудити на ефективността на обработването за дългосрочните клиенти.

„Тяхната екип преработи нашата hidrauliчна манифолд, намаливайки теглото й с 22%, без да компрометира редовете на налягане. Това е инженерско партньорство!“

- Алекс Р., Главен инженер в WF

По-умният път към прецизни части

Докато много доставчици обещават качество, ние го проектираме във всяка молекула:

-

Бързост съчетана с прецизност : 45000мм/мин бързи ходове + 1500x5500мм капацитет за резане на големи части без забавяния по време на изпълнение

-

Костова ефективност : Автоматизирано гнездене спестява 15-30% от материала спрямо ръчното планиране

-

Глобално готови : Мултиезични контролни системи (АН/ИСП/ФР/РУ) и логистика оптимизирана за INCOTERM

Готови ли сте да превърнете вашия дизайн в прецизни продукти, готови за пазара?

→ Заявка за молниен цитат с нашата платформа с подкрепа на ИИ (приети качванания: STEP/IGES/SOLIDWORKS)

→ Изтеглете нашия ръководител по материали за CNC (60+ метални/пластмасови градации с параметри за обработка)

→ Запланирайте виртуална фабрична екскурзия – видете бъдещите си части, докато се формират!

|

CNC Токарене, CNC Фрезиране, Лазерно Разрязване, Изкачване, Въртене, Прожектиране, Штампиране, Електрическа Изибна Обработка (EDM), Инжекционно Молдване |

|

Алуминий: серия 2000, серия 6000, 7075, 5052 и др. |

Неръжавеща оцетал: SUS303, SUS304, SS316, SS316L, 17-4PH и т.н. |

Оцетал: 1214L/1215/1045/4140/SCM440/40CrMo и т.н. |

Мед: 260, C360, H59, H60, H62, H63, H65, H68, H70, Бронза, Мед |

Титан: Клас F1-F5 |

Пластмаса: Ацетал/ПОМ/ПА/Нилон/ПЦ/ПММА/ПВХ/ПУ/Акрил/АБС/ПТФЕ/ПИК и др. |

|

Анодиране, Шарикова емисия, Силк скрийн, PVD покритие, Цинк/Никъл/Хром/Титан покритие, Пощипване, Боядисване, Пудърено облагане, Деактивация, Электрофозис, Електро полиринг, Рифлене, Лазер/Гравюра/Етчинг и т.н. |

|

±0.002 ~ ±0.005мм |

|

Мин Ra 0.1~3.2 |

Прецизност при резане за вашите производствени нужди.

Поверете се на експертите в CNC обработка!

Алуминий

Толеранция: +/- 0.01~+/-0.005 мм

Материал: 2024, 5083, 6061, 6063, 7075 и т.н.

Обработка на повърхността: O окисление, электрофорез, шлифовка с песък, електролитно покриване, химически обработки, боядисване, твърдо анодиране, термична обработка и т.н.

Нержавеща оцел/Оцел/Сплав от титан

Толеранция: +/- 0.01~+/-0.005 мм

Материал:

SUS303, SUS304, SS316, SS316L, 17-4PH, и т.н.

1214L/1215/1045/4140/SCM440/40CrMo, и т.н.

TA1, TA2/GR2, TA4/GR5, TC4, TC16, TC18, TC21, TC22, TC26, TC118B и т.н.

Обработка на повърхност: E електрооблагане, галванизиране, боядисване, окисляване, полирване, чупен grind, пасивация, термична обработка, киселинна чистка, шотпине и т.н.

Мед / Медно-цинкови сплави

Толеранция: +/- 0.01~+/-0.005 мм

Материал: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90, C11000, C12000, C22000, C26000, C28000, C36000 и т.н.

Обработка на повърхността: E електрооблагане, оловна обработка, боядисване, оксидация, полирване, спрей обработка, термична обработка, киселина чистене, шаровидно обработване и т.н.

Пластмаса

Толеранция: +/- 0.01~+/-0.005 мм

Материал: Формалдегид / POM / PA / Нилон / PC / PMMA / PVC / PU / Акрил / ABS / PTFE / PEEK и т.н.

Обработка на повърхността: Боядисване, песъчен стрийбинг, боядисване, киселина чистене, алкално чистене, анодизиране, ионна имплантация, термично прехвърляне на печат, гравюране и т.н.

Обработка на повърхността на детайли, изработени чрез CNC фрезиране.

(1) Физическа обработка на повърхността: песочен бластинг, шлифовка, метална градация, полирване, катане, полирване, цедене, боядисване, порошково боядисване, силк-screen принтиране, пад принтиране, воден transfer принт, електрофореза и т.н. (2) Химическа обработка на повърхността: синьо червене, фосфатиране, декапиране, безелектрично гальванизиране, TD обработка, QPQ обработка, карбуриране, нитриране, химическо оксидиране, пасивиране и т.н. (3) Електрохимическа обработка на повърхността: анодно оксидиране, твърдо анодно оксидиране, електролитно полирване, електрогальванизиране и т.н. (4) Модерна обработка на повърхността: химическа парова депозиция CVD, физическа парова депозиция PVD, ионна имплантация, ионно гальванизиране, лазерна обработка на повърхността и т.н.

20+Години на CNC обработка

Способност за доставка: 300,000Бройки/Месец

Оси на машината: 3,4,5,6

Толеранция: +/-0.01~+/-0.005мм

Сертификация:

ISO9001:2015,AS9100D,ISO13485:2016,ISO45001:2018,IATF16949:2016,ISO14001:2015,RoSH,CE и др.

Запазваме се на прецизни форми, CNC токарни части, CNC фрезерни части. Нашите продукти се използват предимно за индустриални машини и медицинско оборудване. Можем да правим продукти от материали като неръжавяваща оцел, оловен сплав, мед, алуминий, PEEK, бронзов сплав, найлон, дерлин, PTFE и др. Повърхностната обработка, която можем да осъществим, включва анодиране, черен оксид, порошково опаковане, високо полирване и хромиране. За да се уверим в критичните размери, ние импортираме машините си от САЩ и Япония. Минималната точност, която можем да постигнем, е 0,005-0,01 милиметър. Нашите инженери са доста опытни и могат да предоставят услуга за производство по поръчка (OEM) или да дадат някои съвети, ако сте нуждаещи. Нашите работници са обучени и следват ISO стандарт. Изберете ни PFT и ще преви mej очакванията ви. Ако има нещо, което можем да помогнем, или ако ви трябва повече информация, моля, не колебайте се да се свържете с нас.

Добре дошли в свет, където прецизността се среща с превъзходството, където нашите услуги за обработка са оставили следа от задоволени клиенти, които не можеха да не славят нашите достойнства. Горд сме да представим броят положителни отзиви, които говорят много ясно за изключителното качество, надеждност и занаят, които определят нашата работа. Това е само част от обратната връзка от клиентите, имаме още повече положителни отзиви, добре дошъл си да научиш повече за нас.

1. Дали сте производител или търговска компания? Ние сме фабрика, situирана в Шенжен, Китай, с 20 годишно богат опит.

покриващ 6000 квадратни метра. Пълни.facilities, включително 3D инспекционно оборудване за качество, ERP система и 40 машина. Ако е необходимо, можем да ви предоставим сертификати за материалите, извеждане на примерен отчет за качество и други отчети.

2. Как да получим оферта?

Детайлирани чертежи (PDF/STEP/IGS/DWG...), включващи качество, дата на доставка, материали, качество, количество, обработка на повърхността и друга информация.

3. Мога ли да получа оферта без чертежи?

Може ли инженерната ни екип да направи чертеж за моето творчество? Разбира се, сме също така радостни да получим вашите примери, снимки или детайлирани размерни набросъци за точна оферта.

4. Можете ли да предоставите примерни образци преди масовото производство?

Разбира се, таксата за образец е необходима. Ако е възможно, ще бъде възвръщана по време на масовото производство.

5. Каква е датата за доставка?

Обикновено примерът продължава 1-2 седмици, а партийното производство - 3-4 седмици.

6. Как контролирате качеството?

(1) Проверка на материалите - проверете повърхността и приблизителните размери на материалите.

(2) Първоначална проверка на производството - да се гарантира

критичните размери при масовото производство.

(3) Пробна проверка - проверете качеството преди доставка до склада.

(4) Предварителна проверка преди отпращане - 100% проверка от помощник-QC преди отпращане.

7. Екип за следпродажби услуги

Ако имате проблеми след получаването на продукта, можете да дадете обратна връзка чрез гласови звъни, видеоконференции, имейли и т.н. в рамките на един месец. Нашата екип ще ви предостави решения в рамките на един седмици.