Machining is a important part of making many things we use daily, like cars or smartphones. Engineers have to know some key things that can effect how good the machining turn out. At Swords Precision, we understand that knowing these factors well help to make sure parts we produce are high quality. When engineers look at stuff like the tools, materials, and also the environment, they can choose better. This make products that last longer and work properly. So we will check some essential machining factors and where you can find good machining services.

What Are the Essential Machining Factors for Quality Production?

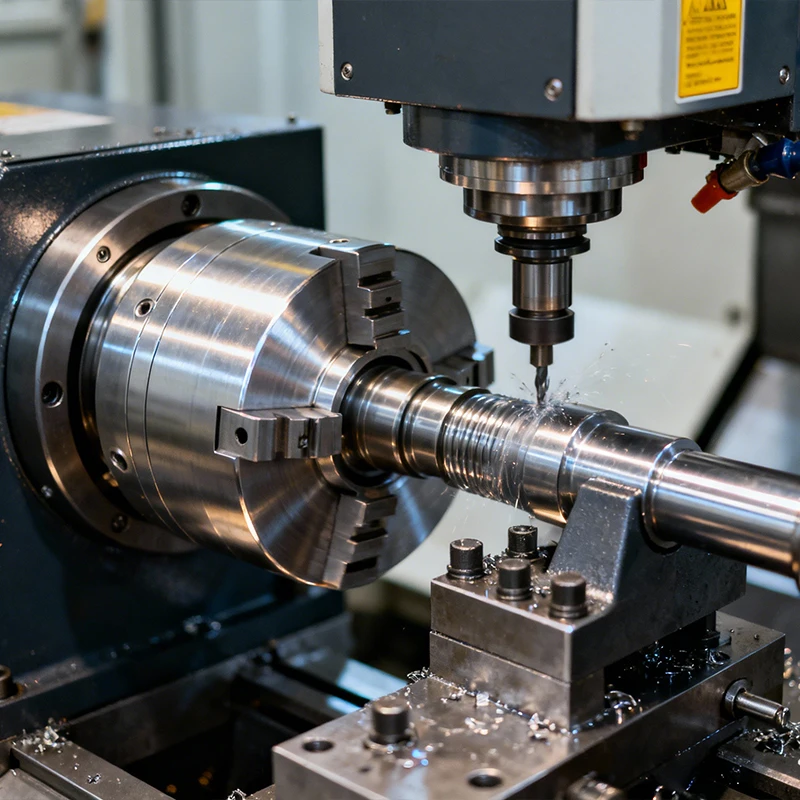

In machining, lots of things can change the quality of final product. First the material type is big role. Different metals or plastics act not the same when machined. For example aluminum is softer and easy to cut compare to steel, so its good for some uses. Next tools are very crucial. They need be sharp and correct type for material. If tools are dull, it cause bad cuts or even damage material. Machine speed matter too. If run too fast, machine can overheat and ruin the part. But if too slow, it take long time and cost more. Also setup of machine is important. When part not hold tight, it move during process and make mistakes. And environment where machining happen affect quality. Dust, moisture or temperature can change machine working and material behave. Engineers at Swords Precision always think about these to produce every piece with high standard. This careful way help parts fit perfect and function as they should.

Where to Find Reliable Machining Services for Your Business Needs

When business need machining service, its important find reliable one. Start with companies that have good reputation. You can ask other business for suggestion or look online reviews. A good service should know different materials and machining types. This show they handle various project. At Swords Precision we proud of our experience and many services. Its also good to visit facility if you can. You see equipment and how they work. Clean and organize shop usually mean they care about quality. Don’t forget talk your specific needs with provider. Good communication make sure all understand same. Discuss time, cost, and special requirement. Quality services are open about process and price. Also see if they give support after done. Companies that stand behind work will help if problem come later. At Swords Precision we like build strong relation with clients so they get best service.

Choosing the Right Machining Method for High-Quality Parts

Machining is process of shaping material, often metal, into specific parts. For engineers in company like Swords Precision its important know which method give best quality. One popular is CNC Machining. CNC mean Computer Numerical Control. It use computer to control machine for cutting or shaping. Because computer precise, CNC usually give high quality with smooth finish and exact size. Another is 3D printing. It build part layer by layer, so can make complex design hard with old way. Many engineers at Swords Precision like 3D printing cause it make prototype fast to test idea before big production. But choose right material for each method is key. Different metal and plastic react not same, it effect strength and look of product. Engineers should always consider material type to pick best method. And quality control is vital too. Testing at stages catch mistake early. This way final product meet high standard customers expect from Swords Precision.

Strategies to Reduce Costs While Maintaining Machining Excellence

Reducing costs but keep machining excellent is challenge engineers face daily. One main way to cut cost is improve efficiency. Means do same work faster or less waste. For example high-speed machining save time, machine work quick without lose quality. At Swords Precision engineers can optimize cutting tools. Sharp and strong tools mean less replace and repair, save money. Another is train workers good. When they know operate machine efficient, mistake reduce and workflow better. Also plan ahead help save. Think whole production when design part. By choose easy and cheap design from start, cost down. Finally work with suppliers can get better deal on material and tool. Strong relation let Swords Precision negotiate price and have reliable supply without spend too much.

Key Machining Technology Trends Wholesale Buyers Should Watch

Staying update with new trends in machining tech is essential for wholesale buyers. One exciting is automation. Automated machine work all time, produce part faster than people. This speed up production and reduce cost, good for buyer want efficiency. Another is AI in machining. AI monitor machine and predict maintenance need. So companies like Swords Precision avoid sudden break that cause delay and cost. Also smart technology change how design and make product. With smart tool, engineer track machine performance real time and adjust quick. Sustainability is focus too. More company want eco friendly material and process, use less energy and less waste. This appeal to buyer care environment. Lastly customized product rise big. Customer want unique item for their need. This make company use flexible CNC machining parts that adapt different order. By watch these trends, wholesale buyers can get best product and service from place like Swords Precision.

Table of Contents

- What Are the Essential Machining Factors for Quality Production?

- Where to Find Reliable Machining Services for Your Business Needs

- Choosing the Right Machining Method for High-Quality Parts

- Strategies to Reduce Costs While Maintaining Machining Excellence

- Key Machining Technology Trends Wholesale Buyers Should Watch