Hey everyone! If you’re in manufacturing, engineering, or just curious about where industrial tech is headed, you’ve probably heard the buzz about CNC machining. Today, we’re breaking down the global CNC machining market’s growth trajectory, key drivers, regional shifts, and tech innovations shaping the next five years. Let’s dive in.

The Big Picture: Market Size & Growth

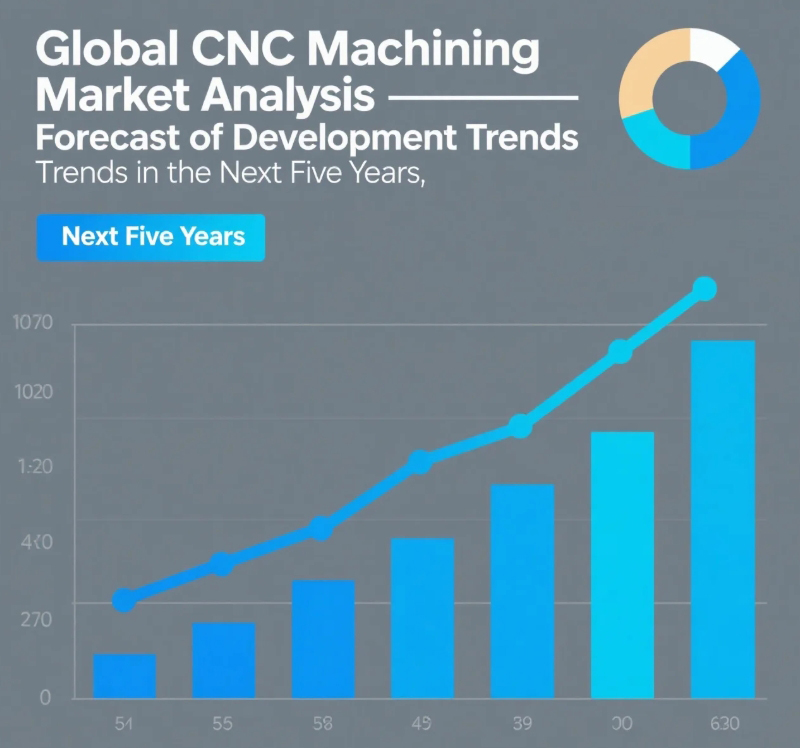

The CNC market is on a solid upward climb. Here’s the breakdown:

- 2023 Baseline: The market was valued at $731–952 billion globally .

- 2029 Projection: Experts predict it’ll hit $1.17–1.37 trillion by 2029 .

- Growth Rate: A steady 5.0–9.9% CAGR (Compound Annual Growth Rate) through 2029 .

Why the surge? Demand for high-precision parts (think aerospace, medical devices, and EVs), automation trends, and smarter factories are pushing adoption .

Key Growth Drivers: What’s Fueling the Boom

1.EV & Aerospace Demand:

- Electric vehicles need ultra-precision components (e.g., motor housings, battery parts). The auto sector’s CNC demand is growing at ~13% CAGR .

- Aerospace relies on CNC for turbine blades and structural parts, driving $155B in applications by 2032 .

2.Automation & Industry 4.0:

- Factories are ditching manual processes for AI-driven CNC systems that optimize tool paths, predict maintenance, and slash errors .

3.Asia-Pacific Dominance:

- APAC will hold 39% of the global market by 2024, led by China, Japan, and India. Cheap labor, tech investments, and booming industrial sectors are key .

Tech Innovations Changing the Game

The next-gen CNC machine isn’t your grandpa’s lathe. Here’s what’s emerging:

- AI & Machine Learning: Algorithms adjust cutting parameters in real-time, boost precision, and reduce waste by 20–30% .

- IoT Integration: Sensors track machine health, tool wear, and production rates, enabling predictive maintenance (no more surprise downtime!) .

- 5-Axis Machines: Demand for complex parts is pushing 5-axis CNC growth—the fastest-growing segment .

Regional Hotspots: Where the Action Is

|

Region |

Market Share (2024) |

Growth Outlook |

|

Asia-Pacific |

39% |

Fastest growth (low costs + industrial expansion) |

|

North America |

27% |

Steady demand from aerospace and defense |

|

Europe |

22% |

Automotive and machinery sectors driving innovation |

Challenges Ahead: Hurdles to Watch

- Skilled Labor Shortage: 20% of manufacturers struggle to find trained CNC operators .

- Supply Chain Risks: Material delays (e.g., titanium, specialized alloys) disrupt production .

- High Costs: Advanced CNC systems require big upfront investment—a barrier for SMEs .

The Bottom Line: What It Means for You

The CNC market’s growth is locked in, thanks to automation, EVs, and smarter tech. For businesses:

- Invest in AI-integrated CNC systems to stay competitive.

- Prioritize APAC partnerships for cost efficiency.

- Tackle labor gaps with upskilling programs .