Broaching vs CNC Shaping for Internal Splines in Gearboxes: Complexity & Tooling Costs

Introduction

When designing or repairing gearboxes, one of the recurring challenges is machining internal splines. Two of the most common processes—broaching and CNC shaping—often spark debates among engineers about which is better. The truth is, there is no one-size-fits-all answer. The right choice depends on part geometry, production volume, and long-term cost of tooling.

Having worked with gearbox component production for over a decade, our team has run both broaching machines and CNC shapers on automotive, aerospace, and heavy-equipment projects. In this article, we’ll break down the differences with practical examples, so you can evaluate which method aligns with your specific spline requirements.

What Is Broaching?

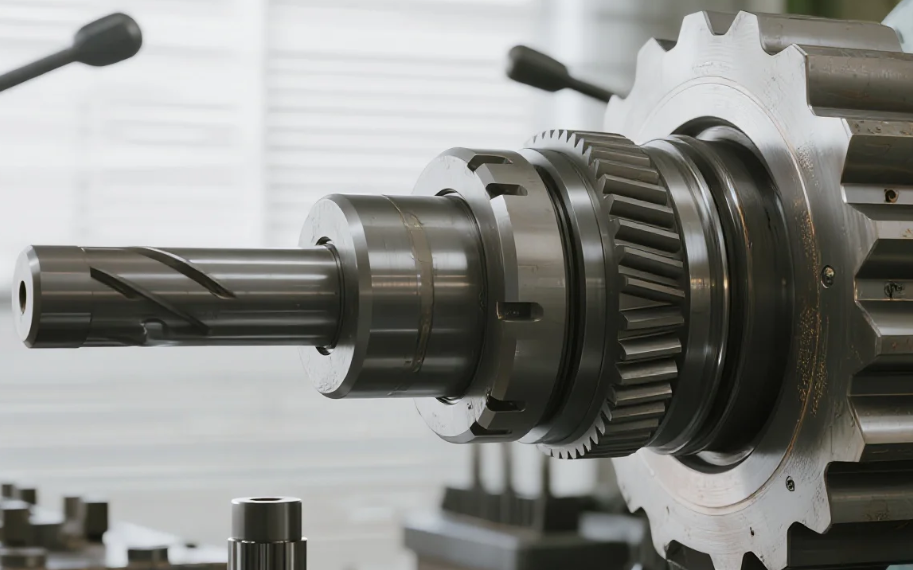

Broaching uses a long, multi-tooth tool that progressively cuts the spline profile as it passes through the bore.

-

Best for: Medium to high-volume runs where spline geometry is standardized.

-

Cycle time: Often less than 20 seconds per part once setup is complete.

-

Surface finish: Excellent, with Ra values around 0.8–1.2 µm.

-

Limitations: High upfront tooling cost ($8,000–$20,000 per broach), limited flexibility when geometry changes.

Case in point: In a 5,000-piece automotive gearbox project, switching from shaping to broaching reduced cycle time by 78% and cut per-part cost by almost $4.20. But when the customer later requested a non-standard modification, a new broach was required—adding six weeks and $12,000 to the project.

What Is CNC Shaping?

CNC shaping (sometimes called slotting) uses a single-point tool that reciprocates inside the bore, cutting one spline tooth at a time.

-

Best for: Low- to medium-volume production, prototypes, or custom spline geometries.

-

Cycle time: Slower, ranging from 3 to 7 minutes depending on the spline count.

-

Flexibility: Tooling cost is low (typically $200–$500 for a form tool), and design changes only require CAM adjustments.

-

Limitations: Longer machining time and higher tool wear for hardened materials.

Shop-floor insight: For an aerospace reduction gearbox with a complex 27-tooth internal spline, broaching wasn’t even possible due to tool clearance issues. CNC shaping delivered the part at acceptable tolerances within 4.8 minutes per piece—still competitive for a 300-piece lot size.

Complexity and Tooling Costs Compared

| Factor | Broaching | CNC Shaping |

|---|---|---|

| Initial Tooling Cost | High ($8k–$20k) | Low ($200–$500) |

| Change Flexibility | Requires new broach | Simple CAM change + tool swap |

| Cycle Time | 15–30 seconds/part | 3–7 minutes/part |

| Best for | High-volume, standard splines | Prototyping, custom/low-volume |

| Part Complexity | Limited by broach design | High flexibility |

Which Process Should You Choose?

The decision often comes down to balancing volume vs flexibility:

-

If you’re making tens of thousands of gearboxes with standard spline geometry → Broaching wins for cost per part.

-

If you’re in prototype development, low-volume production, or dealing with non-standard splines → CNC shaping provides the agility you need.

-

For medium runs (500–2,000 pieces), many shops hybridize: shaping prototypes first, then investing in a broach only once geometry is frozen.

Practical Takeaways for Engineers and Buyers

-

Calculate lifetime part volume before committing to broaching tooling.

-

Check part geometry and tool clearance—not all internal splines are broachable.

-

Evaluate future design changes—a single spline tweak can make an expensive broach obsolete.

-

Consider subcontracting: Some machine shops keep a library of standard broaches to amortize costs across multiple customers.

Both broaching and CNC shaping are proven methods for producing internal splines in gearboxes, but their suitability depends on your priorities. Broaching excels in high-volume, repeatable jobs, while CNC shaping gives unmatched flexibility for complex or low-quantity projects. By carefully weighing complexity and tooling costs, engineers and purchasing teams can avoid unnecessary expense and ensure gearbox reliability.