Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

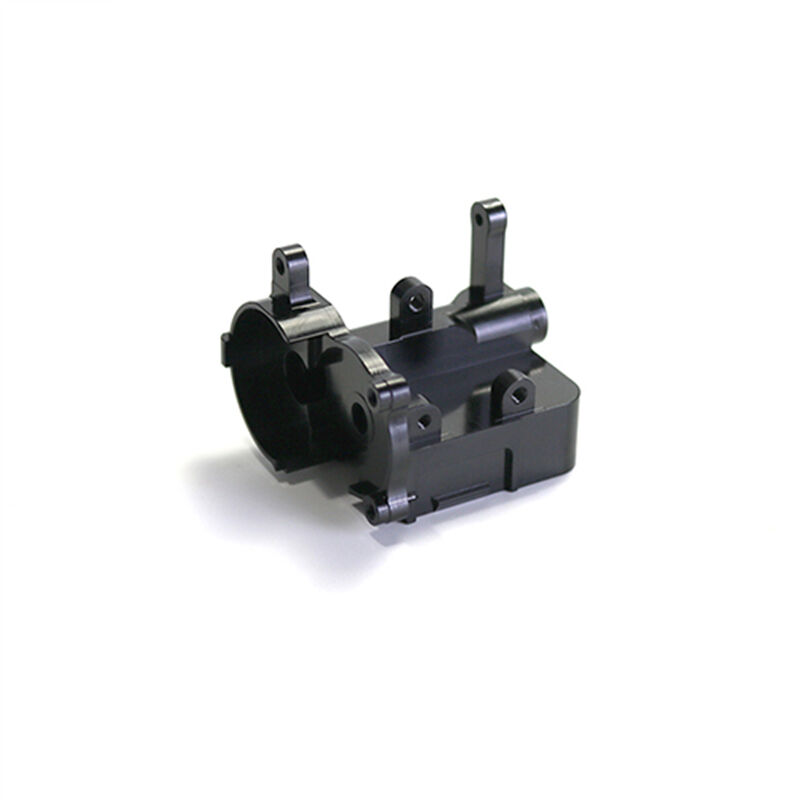

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Model Number:OEM

Keyword:CNC Machining Services

Material:stainless steel aluminum alloy brass metal plastic

Processing method :CNC milling

Delivery time:7-15 days

Quality:High End Quality

Certification:ISO9001:2015/ISO13485:2016

MOQ:1Pieces

In the fast-paced world of manufacturing, where precision, speed, and cost-efficiency are paramount, one technology stands out as a game-changer: Computer Numerical Control (CNC). CNC machining is transforming industries by enabling factories to achieve unprecedented levels of accuracy, automation, and scalability. This article explores how CNC technology is reshaping factory manufacturing and why it’s becoming a cornerstone for businesses aiming to stay competitive in today’s market.

CNC refers to a process where a computer controls the movements of machinery, tools, and equipment to create highly precise parts and products. CNC machines can include milling machines, lathes, routers, and grinders, all programmed to follow a specific set of instructions that dictate their operation.

This technology eliminates the need for manual operation, allowing for automation in manufacturing processes. The result? Consistently high-quality products, faster production times, and reduced human error.

1. Precision and Accuracy

At the heart of CNC technology is its ability to deliver unparalleled precision. Traditional manual machining methods often depend on the skill of the operator, which can lead to inconsistencies or errors. CNC machines, on the other hand, follow exact instructions based on detailed designs or blueprints, resulting in products that meet stringent tolerances.

For industries such as aerospace, automotive, and medical device manufacturing—where even the slightest deviation from a design can lead to catastrophic consequences—CNC provides a level of reliability that is simply unmatched.

2. Increased Efficiency and Productivity

CNC machines operate quickly and consistently, reducing the time needed for each operation. Unlike manual processes, CNC machines can work continuously, 24/7, with minimal downtime. They can also be easily reprogrammed to handle different tasks, making them incredibly versatile.

This efficiency is particularly beneficial in industries where short production runs or rapid prototyping are crucial. Manufacturers can produce parts faster, allowing them to meet tight deadlines and keep pace with changing market demands.

3. Cost-Effectiveness

Though the initial investment in CNC machinery can be substantial, the long-term benefits far outweigh the cost. CNC machines reduce the need for manual labor, lower the risk of costly errors, and reduce material waste by achieving precise cuts and measurements.

Additionally, CNC allows for batch production, meaning manufacturers can produce large quantities of identical parts without sacrificing quality. This scalability is a key factor in driving down per-unit production costs.

4. Flexibility in Design

One of the most attractive features of CNC machining is its flexibility when it comes to design. CNC machines can work with a wide range of materials, including metals, plastics, wood, and composites. Moreover, they can execute intricate designs and complex geometries that would be impossible—or prohibitively expensive—using traditional manufacturing techniques.

Design modifications are also simpler to implement. With CNC, changes to a product’s design can be made quickly and easily through adjustments to the program, rather than requiring entirely new tools or molds. This makes CNC perfect for industries that require frequent design iterations or rapid adaptation to new market trends.

5. Automation and Reduced Human Error

One of the most significant advantages of CNC in factory manufacturing is automation. CNC machines can be programmed to run autonomously, reducing the need for human operators on the shop floor. This not only speeds up production but also reduces the likelihood of human error, improving the overall quality of the end product.

Furthermore, automated processes mean that workers can focus on overseeing operations, performing quality control, and handling tasks that require problem-solving and creativity—ultimately optimizing human resources in a factory setting.

6. Customization and Small-Batch Production

For many industries, customization is a growing demand. CNC machining makes it easier for manufacturers to produce customized or small-batch products with minimal extra cost. Whether it’s a one-off prototype or a limited-edition part, CNC technology allows factories to switch between different designs with little downtime, making it ideal for businesses that need to cater to specific customer needs without massive overhead.

1.Aerospace and Defense

In highly regulated industries like aerospace and defense, precision is not just a requirement; it’s a matter of safety and performance. CNC machining is widely used to manufacture components for aircraft, satellites, and military equipment. CNC ensures that each part meets rigorous specifications, often down to a fraction of a millimeter, ensuring the highest standards of reliability and durability.

2.Automotive

The automotive industry benefits greatly from CNC machining. It’s used to create everything from engine components to body parts, offering manufacturers the ability to quickly prototype new designs and efficiently produce high volumes of parts. As the push toward electric vehicles grows, CNC’s flexibility allows manufacturers to adapt to new materials and evolving designs.

3.Medical Devices

CNC machining is critical in the medical field, where precision is essential. Components such as surgical instruments, prosthetics, and implants are often created using CNC machines. The ability to manufacture products that are both precise and reliable is a significant reason why CNC is trusted in medical device production.

4.Consumer Electronics

Consumer electronics, from smartphones to wearables, require precise manufacturing for tiny components such as circuit boards, connectors, and housings. CNC machines are capable of producing these delicate components with incredible accuracy, helping manufacturers meet the tight tolerances needed for modern electronic devices.

As technology advances, CNC machines are becoming even more sophisticated. The integration of Industry 4.0—which includes smart sensors, IoT connectivity, and AI-driven optimization—means CNC machines will not only be more efficient but also smarter and more adaptable.

With the rise of additive manufacturing (3D printing) in conjunction with CNC, manufacturers now have the capability to combine subtractive and additive processes to produce even more complex parts with fewer limitations.

Furthermore, CNC machines are becoming more accessible to small and medium-sized enterprises (SMEs), allowing even smaller manufacturers to compete with larger counterparts in terms of precision and production speed.

CNC machining is not just a trend; it’s the future of factory manufacturing. By delivering unmatched precision, improving efficiency, reducing costs, and offering flexibility in design, CNC technology is transforming industries across the board. As the manufacturing landscape continues to evolve, businesses that embrace CNC will be better positioned to meet the demands of the modern market—delivering quality products faster and more cost-effectively than ever before.

Whether you’re looking to streamline your production process, improve product quality, or innovate with new designs, CNC offers the tools you need to stay ahead of the curve.

Are you ready to take your manufacturing to the next level? Investing in CNC technology could be the key to unlocking new opportunities and ensuring long-term success in an increasingly competitive global marketplace.

Q:What is the difference between CNC and manual machining?

A:CNC machining is automated and controlled by a computer, while manual machining requires human skill and physical control of tools. CNC offers higher precision, speed, and repeatability compared to manual machining.

Q:Can CNC machines be used for prototyping?

A:Yes! CNC machines are excellent for prototyping because they can quickly turn CAD designs into physical models, allowing for rapid iteration and testing of new ideas.

Q:Is CNC technology suitable for small businesses or home workshops?

A:Yes, CNC technology is accessible to small businesses and even home workshops. Many companies offer compact and affordable CNC machines that can be used for small-scale production, prototyping, and custom designs.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog