Bâtiment 49, Parc Industriel Fumin, Village de Pinghu, District de Longgang

Dimanche Fermé

Lorsque vous entrez dans un atelier de production, le bourdonnement rythmé des machines et l'odeur de pièces plastiques fraîchement moulées créent une atmosphère unique. Ces pièces — allant de composants automobiles à des boîtiers médicaux — sont souvent produites à l'aide de moulage par injection de plastiques , l'un des procédés de fabrication les plus efficaces et évolutifs au monde.

Dans cet article, je vais partager mon expérience directe expliquer le fonctionnement du procédé , le comparer avec d'autres méthodes, et vous donner des conseils pratiques pour choisir le bon fournisseur.

Le moulage par injection de plastique est un processus de fabrication à grand volume où du plastique fondu est injecté sous haute pression dans un moule en acier ou en aluminium. Une fois refroidi, le moule libère une pièce solide précise, durable et reproductible.

Matériaux utilisés : ABS, PP, PC, Nylon, PEEK, et plus encore.

Applications : Tableaux de bord automobiles, boîtiers électroniques, pièces pour dispositifs médicaux, biens de consommation.

Niveau de tolérance : Une précision de ±0,05 mm est réalisable sur des pièces de précision.

✅ D'après mon expérience en usine : nous avons produit un lot de 10 000 clips automobiles en ABS , et le temps de cycle par pièce était de seulement 28 secondes — ce qui montre pourquoi le moulage par injection est imbattable pour la production de masse.

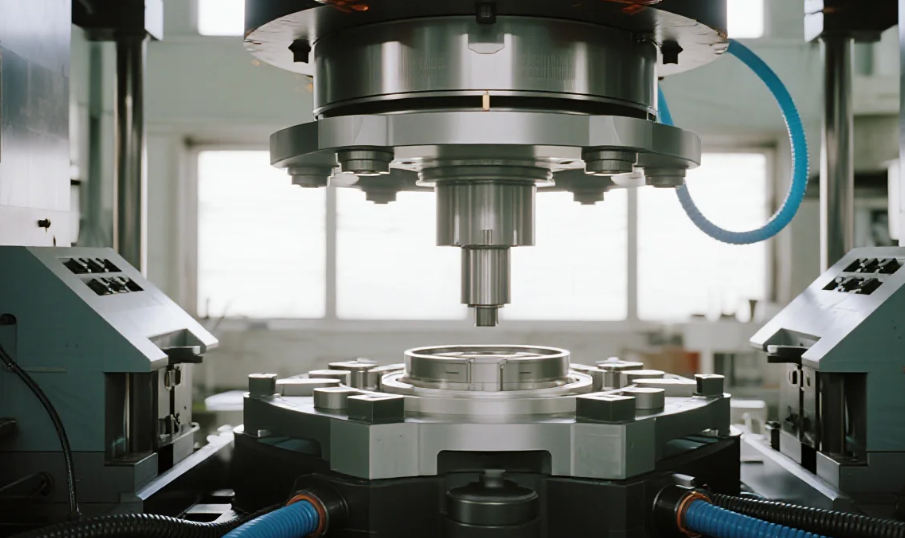

Conception et fabrication du moule – Les ingénieurs créent une conception 3D, suivie d'un usinage CNC ou d'un électro-érosion pour produire le moule.

Préparation des matériaux – Les granulés de plastique sont séchés et introduits dans la trémie.

Injection – Le plastique est fondu et injecté dans la cavité du moule.

Réfrigération – Le plastique en fusion se solidifie à l'intérieur du moule.

Éjection – Des broches d'éjection expulsent la pièce terminée.

Inspection de la qualité – Les pièces sont mesurées avec des machines à mesurer tridimensionnelles (MMT) afin de garantir le respect des tolérances.

? Exemple de temps de cycle : Pour une coque de smartphone standard, le cycle d'injection est d'environ 35–40 secondes .

| Process | Idéal pour | Délai de livraison | Coût par pièce | Limitations |

|---|---|---|---|---|

| Moulage par injection | Production en série (10 000+ pièces) | fabrication du moule en 2 à 6 semaines | Très faible (après amortissement de l'outillage) | Coût élevé du moule |

| impression 3D | Prototypes, petites séries | 1 à 3 jours | Élevé | Résistance et finition limitées |

| Usinage CNC | Faible volume, haute précision | 1 à 2 semaines | Moyenne | Coûteux pour les grandes séries |

| Moulage par soufflage | Pièces creuses (bouteilles, réservoirs) | 2 à 4 semaines | Faible | Formes limitées |

Extensibilité : Idéal pour des séries de 10 000 à 1 000 000 pièces.

Efficacité en termes de coûts : Une fois le moule réalisé, le coût unitaire peut descendre en dessous de $0.10par pièce.

Flexibilité de la conception : Des géométries complexes, des parois fines, des inserts et le surmoulage sont possibles.

Consistance : Chaque pièce correspond exactement à la précédente, garantissant une fiabilité lors du montage.

? Problème résolu : De nombreux acheteurs s'inquiètent de coûts d'outillage . En réalité, des solutions avec moule partagé ou moule rapide peuvent réduire l'investissement initial de 30–50%.

7 Swords Precision : Votre partenaire de confiance en usinage CNC sur mesure

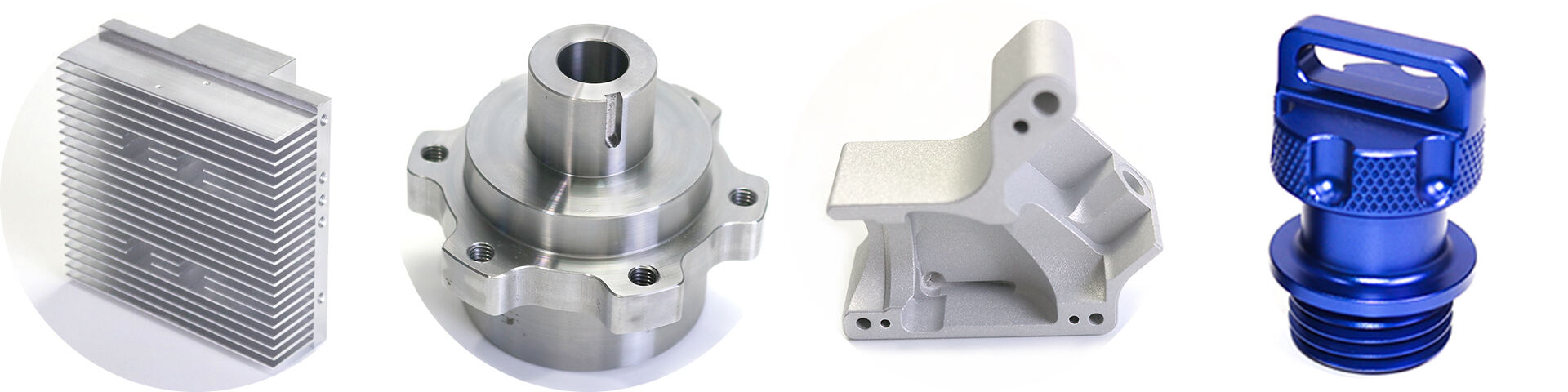

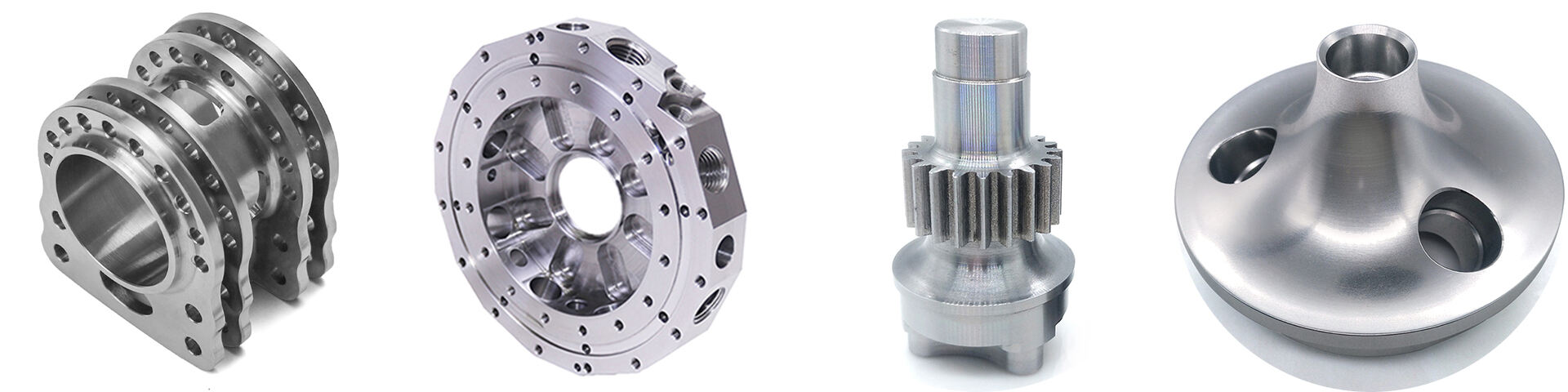

En tant que fournisseur leader de pièces et composants usinés sur mesure, 7 Swords Precision spécialisée dans le tournage et la fraise de prototypes à l'aide de matériaux métalliques de haute qualité. Nous fournissons des produits conçus avec précision adaptés aux exigences spécifiques de divers secteurs industriels. Notre engagement envers l'excellence nous a permis de devenir l'un des principaux fournisseurs de fabrication CNC sur le marché.

Nous sommes fiers de détenir plusieurs certificats de production pour nos services d'usinage CNC, ce qui démontre notre engagement envers la qualité et la satisfaction du client. Notre équipe suit des procédures strictes de contrôle de qualité pour s'assurer que chaque pièce que nous produisons répond aux normes les plus élevées de qualité et de précision

Traitement |

Tournage CNC, Fraisage CNC, Découpe au Laser, Cintrage, Tournage, Découpe par Fil, Emboutissage, Usinage par Décharge Électrique (EDM), Moulage par Injection |

|||||||

Les produits |

Aluminium: série 2000, série 6000, 7075, 5052 etc. |

|||||||

Acier inoxydable: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. Les pièces de rechange sont utilisées pour les pièces de rechange. |

||||||||

Acier : 1214L/1215/1045/4140/SCM440/40CrMo, etc. |

||||||||

Laiton : 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Cuivre |

||||||||

Titane : Grade F1-F5 |

||||||||

Les produits de base doivent être fabriqués à partir de matériaux de la catégorie suivante: |

||||||||

Traitement de surface |

Anodisé, soufflé à la perle, écran de soie, revêtement PVD, revêtement zinc/nickel/chrome/titane, brossage, peinture, revêtement en poudre, passivation, électrophorèse, électropoli, knurl, laser/grave, etc. |

|||||||

Tolérance |

±0,002 ~ ±0,005 mm |

|||||||

Surface roughness |

Min Ra 0.1~3.2

|

|||||||

Droits d'auteur © Shenzhen Perfect Precision Products Co., Ltd. Tous droits réservés — Politique de confidentialité—Blog