बिल्डिंग 49, फूमिन इंडस्ट्रियल पार्क, पिंगहु गांव, लोंगगैंग जिला

रविवार बंद

इसकी कल्पना करें: आपके CAD स्क्रीन पर सुबह 10 बजे एक नए उत्पाद का डिज़ाइन है। दोपहर तक, आप अपने हाथ में एक वास्तविक भौतिक प्रोटोटाइप धारण करना चाहते हैं। यह वही गति है जिसकी अब वैश्विक खरीदार मांग कर रहे हैं—और इसीलिए ऑनलाइन त्वरित प्रोटोटाइपिंग कंपनियाँ आधुनिक निर्माण का एक आवश्यक हिस्सा बन गई हैं।

उन पारंपरिक कार्यशालाओं के विपरीत जिनमें लंबे नेतृत्व के समय और बार-बार ईमेल की आवश्यकता होती है, ऑनलाइन प्रोटोटाइपिंग सेवाएँ तत्काल उद्धरण, डिजिटल ऑर्डर ट्रैकिंग और वैश्विक शिपिंग प्रदान करती हैं—सभी कुछ क्लिक के भीतर।

त्वरित प्रोटोटाइपिंग एक पैमाने के मॉडल या कार्यात्मक घटक को तेजी से बनाने की प्रक्रिया है जो उपयोग करती है एडिटिव मैन्युफैक्चरिंग (3डी प्रिंटिंग) , सीएनसी मशीनिंग , या वैक्यूम कास्टिंग । इससे इंजीनियरों और खरीदारों को निम्नलिखित करने में सक्षम बनाता है:

उत्पाद डिज़ाइन को शुरुआत में ही मान्य करें।

यांत्रिक शक्ति और प्रदर्शन का परीक्षण करें।

हफ्तों तक बाजार में आने के समय को कम करें।

अनुसंधान एवं विकास के चरण में महंगे टूलिंग से बचें।

उदाहरण: एक मेडिकल डिवाइस स्टार्ट-अप ने पारंपरिक मोल्ड निर्माण की प्रतीक्षा करने के बजाय ऑनलाइन 3D-मुद्रित प्रोटोटाइप ऑर्डर करके अपने उत्पाद लॉन्च के समय को 40% तक कम कर दिया।

विभिन्न कंपनियाँ विभिन्न तकनीकों में विशेषज्ञता रखती हैं। सबसे आम ऑनलाइन सेवाओं में शामिल हैं:

| प्रोटोटाइपिंग विधि | के लिए सबसे अच्छा | सामान्य नेतृत्व समय | उदाहरण अनुप्रयोग |

|---|---|---|---|

| 3D प्रिंटिंग (SLA/SLS/FDM) | जटिल ज्यामिति, छोटे बैच | 1–3 दिन | चिकित्सा मॉडल, इलेक्ट्रॉनिक आवरण |

| सीएनसी मशीनिंग | उच्च परिशुद्धता, कार्यात्मक परीक्षण | 3–5 दिन | एयरोस्पेस भाग, ऑटोमोटिव प्रोटोटाइप |

| वैक्यूम कास्टिंग | कम उत्पादन मात्रा, सामग्री परीक्षण | 7–10 दिन | उपभोक्ता उत्पाद के आवरण |

| शीट मेटल प्रोटोटाइपिंग | टिकाऊ प्रोटोटाइप, धातु आवरण | 5–7 दिन | औद्योगिक उपकरण के ढक्कन |

ऑनलाइन सेवा प्रदाता का चयन करते समय, खरीदारी प्रबंधक अक्सर निम्नलिखित की तुलना करते हैं:

गति और लीड समय – क्या कंपनी समान-दिवस या अगले दिन की बचत प्रदान करती है?

सामग्री चयन – प्लास्टिक, राल, धातुओं और उच्च-प्रदर्शन बहुलकों की उपलब्धता।

शुद्धता और सहिष्णुता – विशेष रूप से एयरोस्पेस और ऑटोमोटिव घटकों के लिए महत्वपूर्ण।

मूल्य शफ़ाफ़ी – त्वरित ऑनलाइन उद्धरण बनाम छिपी लागत।

वैश्विक लॉजिस्टिक्स – क्या वे अंतरराष्ट्रीय स्तर पर प्रोटोटाइप को 3–5 दिनों के भीतर भेज सकते हैं?

जर्मनी में हमारे एक ग्राहक ने साझा किया कि ऑनलाइन सीएनसी त्वरित प्रोटोटाइपिंग आपूर्तिकर्ता पर स्विच करने से उनकी बचत हुई लागत पर 15% और लीड टाइम में 7 दिन , जिससे वे अपने ग्राहक के उत्पाद लॉन्च कार्यक्रम को पूरा करने में सक्षम होते हैं।

त्वरित उद्धरण मंच – सीएडी फ़ाइलें अपलोड करें, सेकंडों में मूल्य निर्धारण प्राप्त करें।

पैमाने पर वृद्धि – आपूर्तिकर्ताओं को बदले बिना प्रोटोटाइप से छोटे बैच उत्पादन तक जाएं।

गुणवत्ता आश्वासन – कई कंपनियां ISO 9001 प्रमाणित हैं, जो CMM निरीक्षण रिपोर्ट प्रदान करती हैं।

डिज़ाइन प्रतिक्रिया – स्वचालित DfM (निर्माण के लिए डिज़ाइन) जाँच महंगी त्रुटियों को रोकती है।

प्रश्न 1: ऑनलाइन त्वरित प्रोटोटाइपिंग की कीमत कितनी होती है?

छोटे 3D मुद्रण के लिए कीमतें $50 से शुरू होती हैं और जटिलता के आधार पर CNC-मशीनीकृत धातु प्रोटोटाइप के लिए $500–$2,000 तक जा सकती हैं।

प्रश्न 2: क्या मैं पूर्ण उत्पादन से पहले कम आयतन वाले उत्पादन बैच में प्रोटोटाइप ऑर्डर कर सकता हूँ?

हां, कई कंपनियां ब्रिज निर्माण 50–500 भागों के बैच आकार के साथ प्रदान करती हैं, पूर्ण पैमाने पर उत्पादन में जाने से पहले।

प्रश्न 3: कौन से उद्योगों को सबसे अधिक लाभ होता है?

चिकित्सा उपकरण, उपभोक्ता इलेक्ट्रॉनिक्स, एयरोस्पेस, ऑटोमोटिव और औद्योगिक उपकरण।

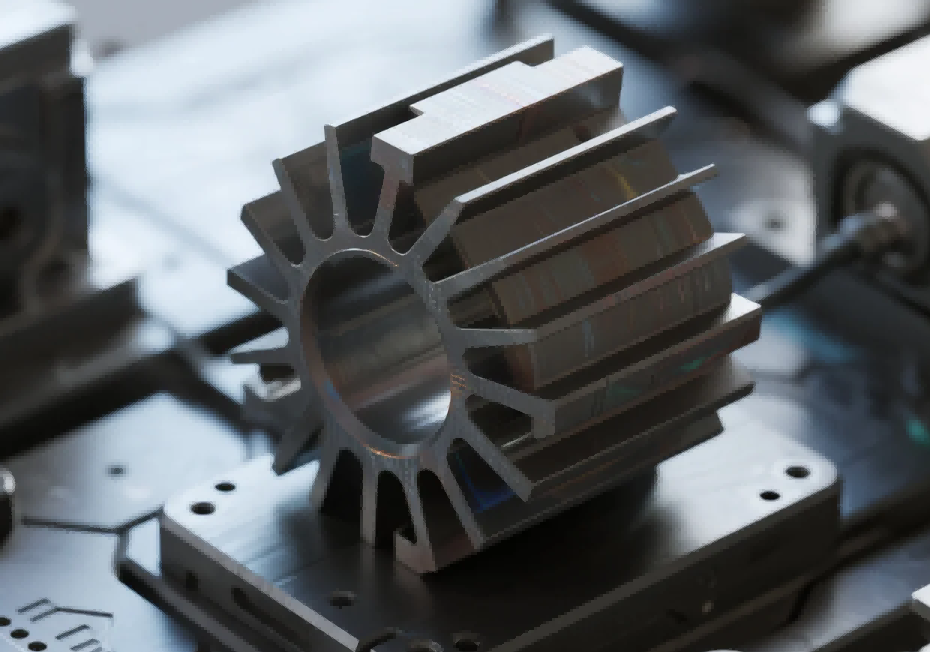

7 स्वॉर्ड्स प्रिसिजन: अपने कस्टम सीएनसी मशीनिंग में आपका भरोसेमंद साझेदार

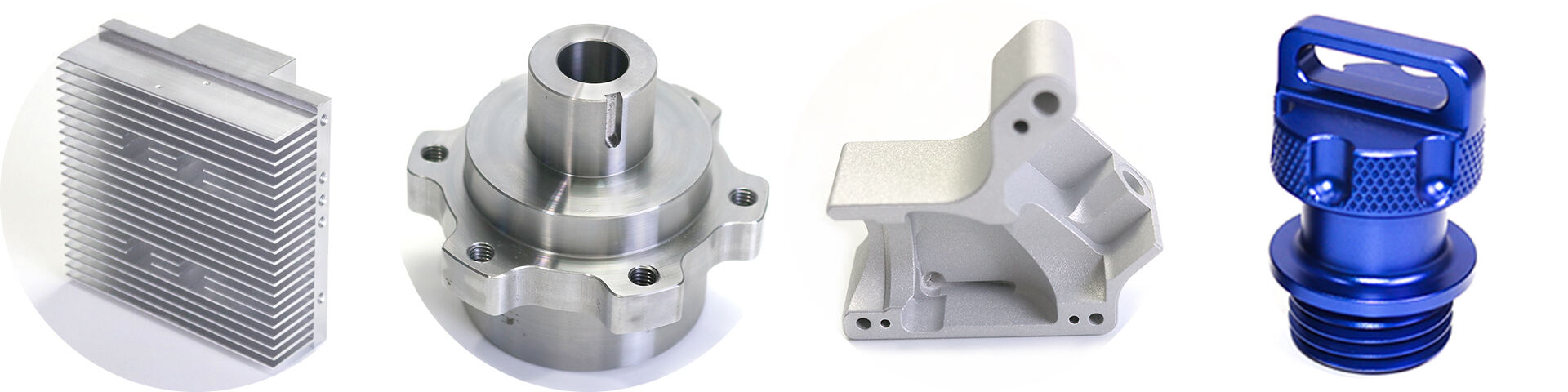

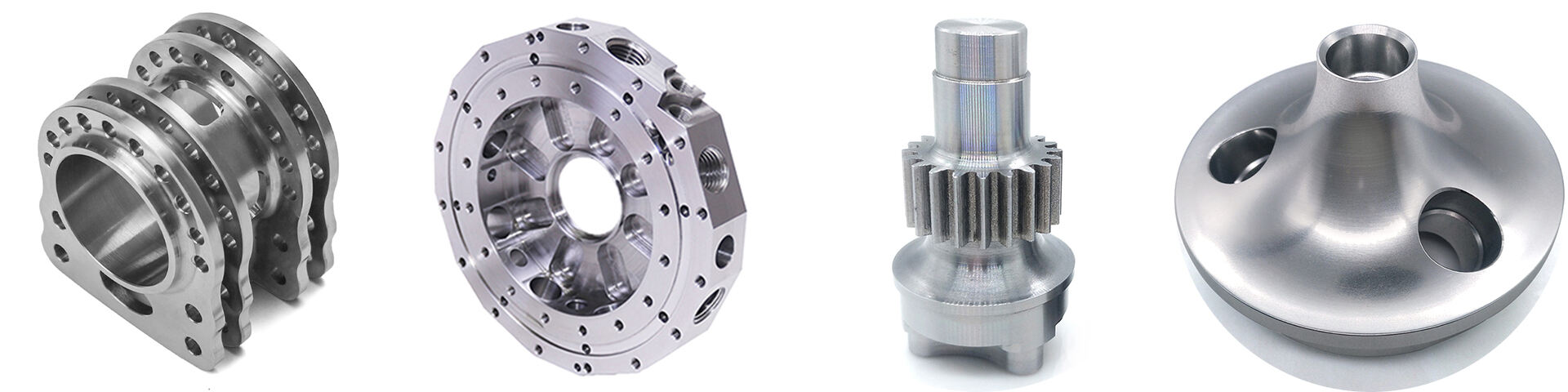

उच्च गुणवत्ता वाली धातु सामग्री का उपयोग करके प्रोटोटाइप टर्निंग और मिलिंग में विशेषज्ञता प्राप्त करने वाले कस्टम सीएनसी मशीनिंग भागों और घटकों के प्रमुख प्रदाता के रूप में, 7 स्वॉर्ड्स प्रिसिजन कार्य करता है। हम विभिन्न उद्योगों की विशिष्ट आवश्यकताओं के अनुसार परिष्कृत इंजीनियरिंग वाले उत्पादों की आपूर्ति करते हैं। हमारा समर्पण बाजार में शीर्ष सीएनसी निर्माण आपूर्तिकर्ताओं में से एक के रूप में स्थापित किया गया है।

हम अपनी सीएनसी मशीनिंग सेवाओं के लिए कई उत्पादन प्रमाणपत्रों के धारक हैं, जो हमारी गुणवत्ता और ग्राहक संतुष्टि के प्रति प्रतिबद्धता को दर्शाता है। हमारी टीम प्रत्येक भाग के उच्चतम गुणवत्ता और सटीकता मानकों को पूरा करना सुनिश्चित करने के लिए कड़ी गुणवत्ता नियंत्रण प्रक्रियाओं का पालन करती है

प्रसंस्करण |

CNC टर्निंग, CNC मिलिंग, लेज़र कटिंग, बेंडिंग, स्पिनिंग, तार कटिंग, स्टैम्पिंग, इलेक्ट्रिक डिस्चार्ज मशीनिंग (EDM), इन्जेक्शन मॉल्डिंग |

|||||||

सामग्री |

एल्यूमिनियम: 2000 सीरीज़, 6000 सीरीज़, 7075, 5052, आदि |

|||||||

स्टेनलेस स्टील: SUS303, SUS304, SS316, SS316L, 17-4PH, आदि |

||||||||

स्टील: 1214L/1215/1045/4140/SCM440/40CrMo, आदि |

||||||||

ब्रास: 260, C360, H59, H60, H62, H63, H65, H68, H70, ब्रोन्ज, कॉपर |

||||||||

टाइटेनियम: ग्रेड F1-F5 |

||||||||

प्लास्टिक: एसीटल/POM/PA/नायलॉन/PC/PMMA/PVC/PU/एक्रिलिक/ABS/PTFE/PEEK आदि |

||||||||

सतह उपचार |

एनोडाइज्ड, बीड ब्लास्टेड, सिल्क स्क्रीन, PVD प्लेटिंग, जिंक/निकल/क्रोम/टाइटेनियम प्लेटिंग, ब्रशिंग, पेंटिंग, पाउडर कोटेड, पासिवेशन, इलेक्ट्रोफोरेसिस, इलेक्ट्रो पॉलिशिंग, नॉल, लेजर/एच/एनग्रेव आदि |

|||||||

सहिष्णुता |

±0.002 ~ ±0.005 मिमी |

|||||||

सतह खुरदरापन |

न्यूनतम Ra 0.1~3.2

|

|||||||

कॉपीराइट © शेनज़ेन परफेक्ट प्रीसिशन प्रॉडक्ट्स को., लिमिटेड. सभी अधिकार सुरक्षित — गोपनीयता नीति—ब्लॉग