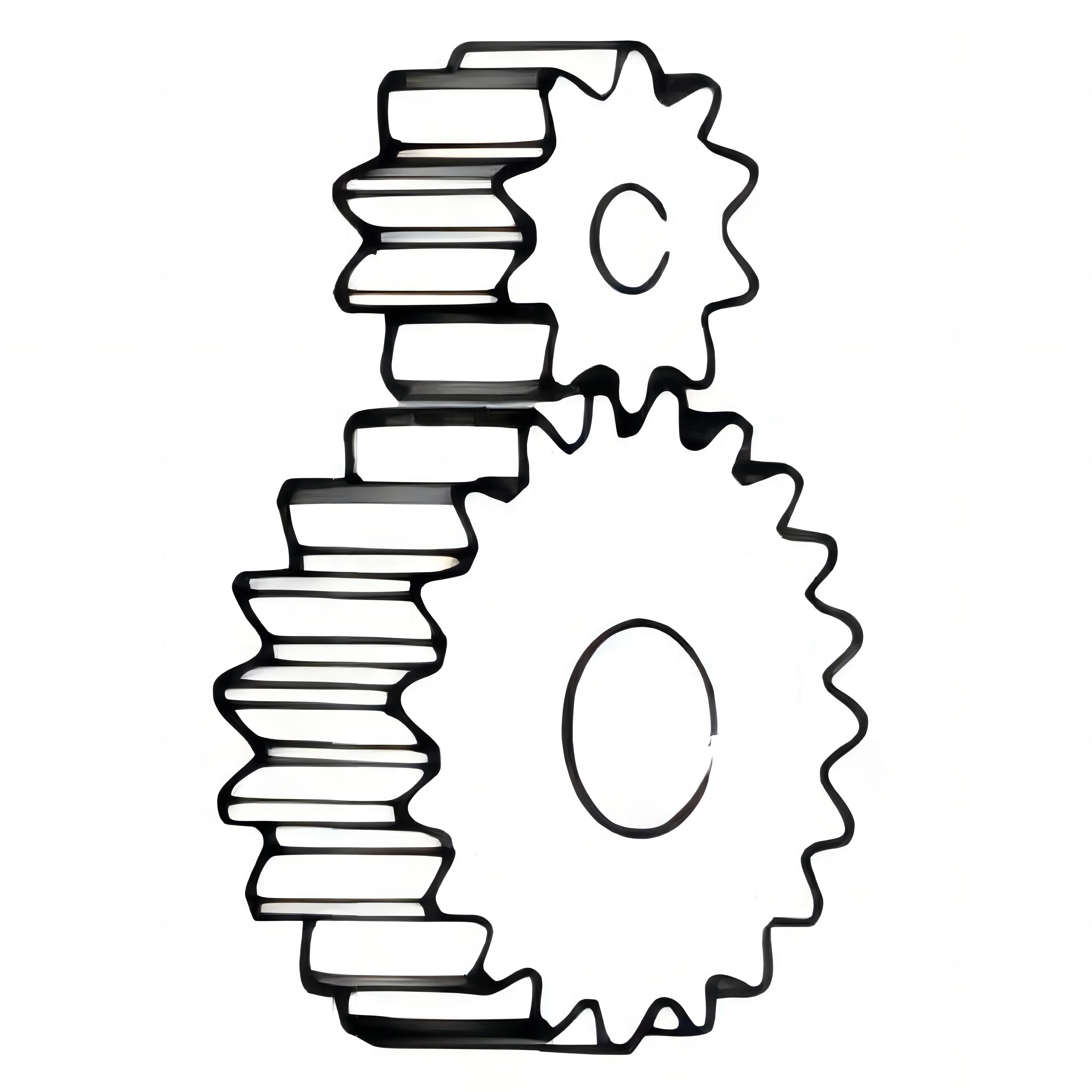

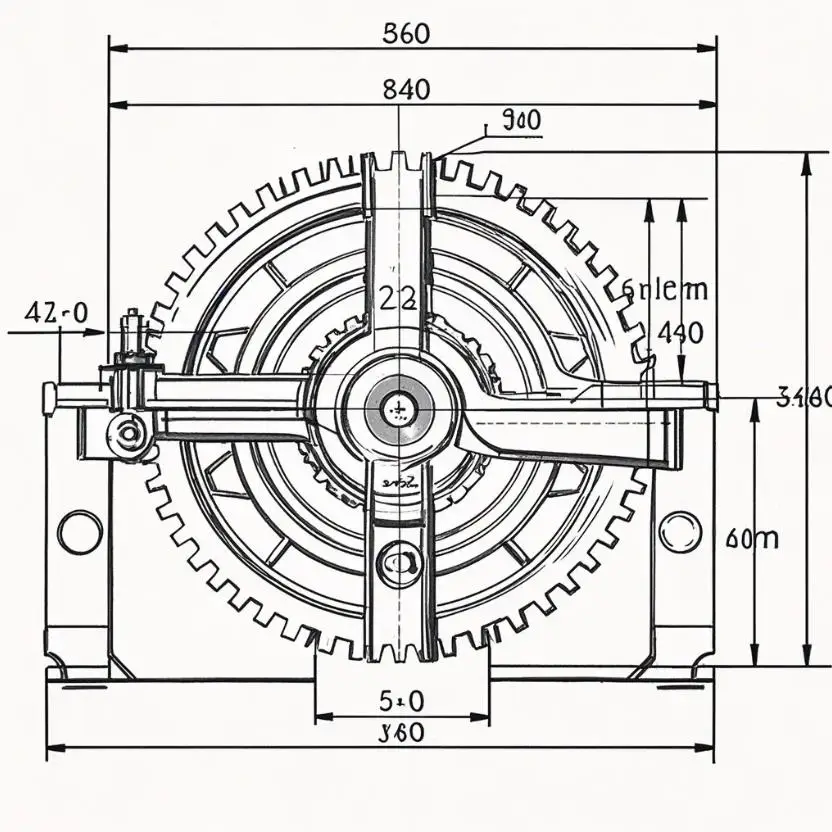

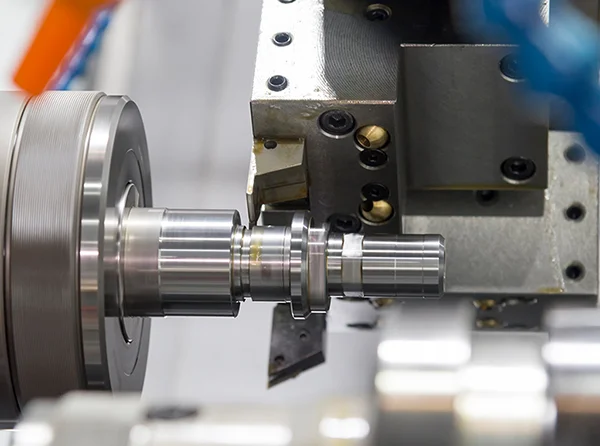

* Բարձրության շրջանի տրամագիծ (PCD): Այն շրջանի տրամագիծն է, որի վրա գիտաթիվները բաշխված են։

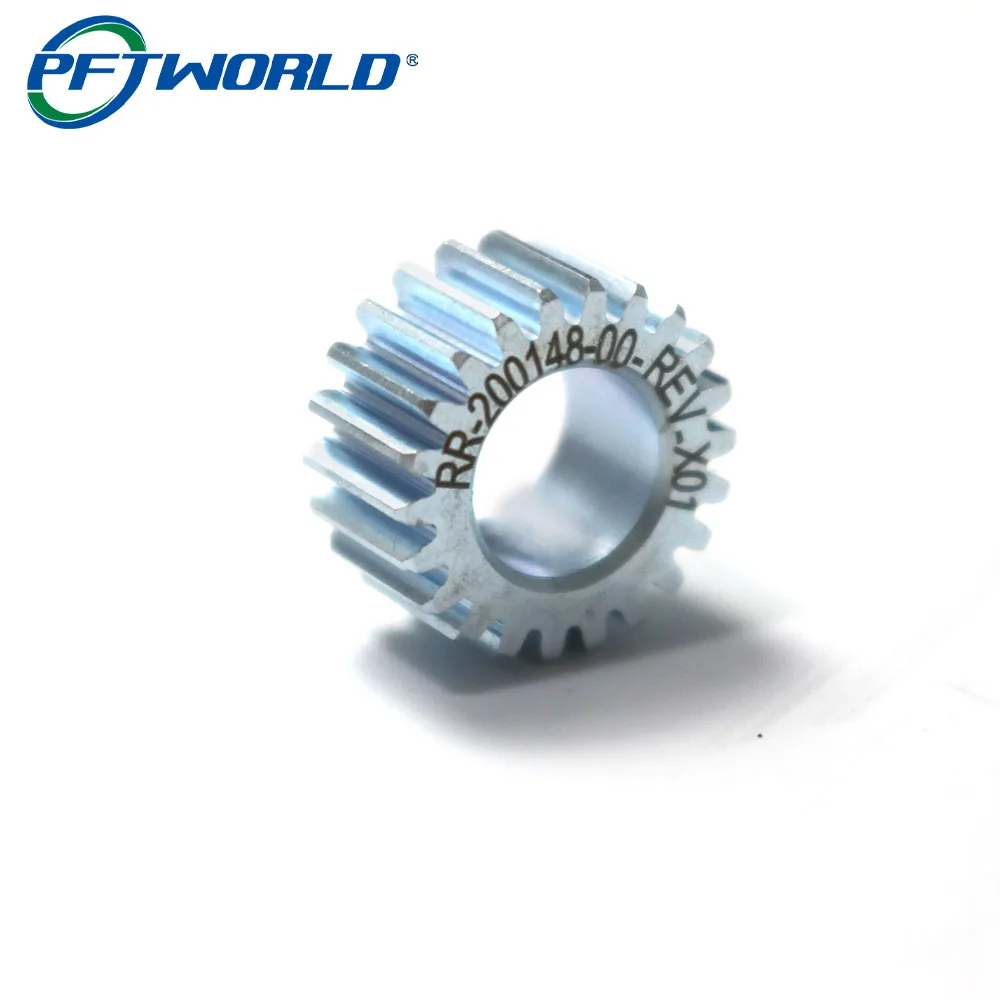

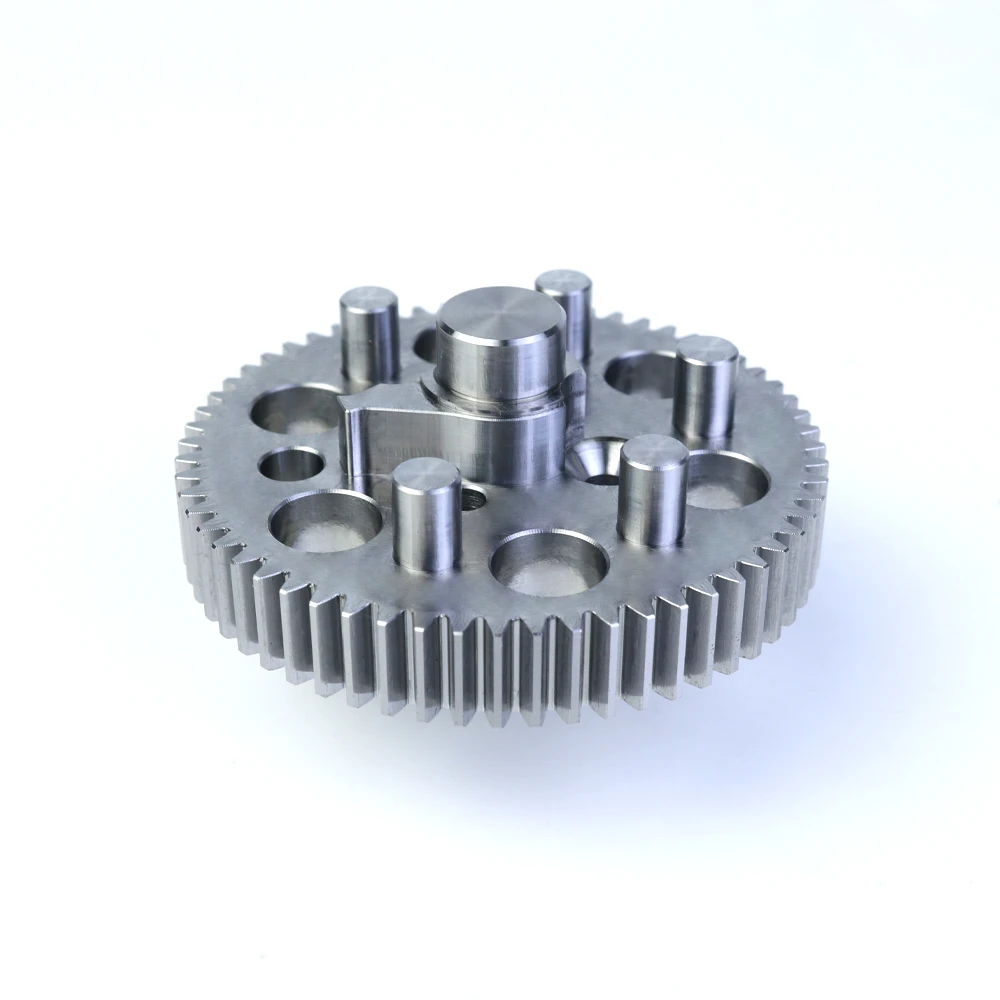

* Արկունիքների քանակ՝ Սա որոշում է չափսերը և գիտաթիվի հարաբերությունը, ազդելով крутящего ուժի և արագության վրա։

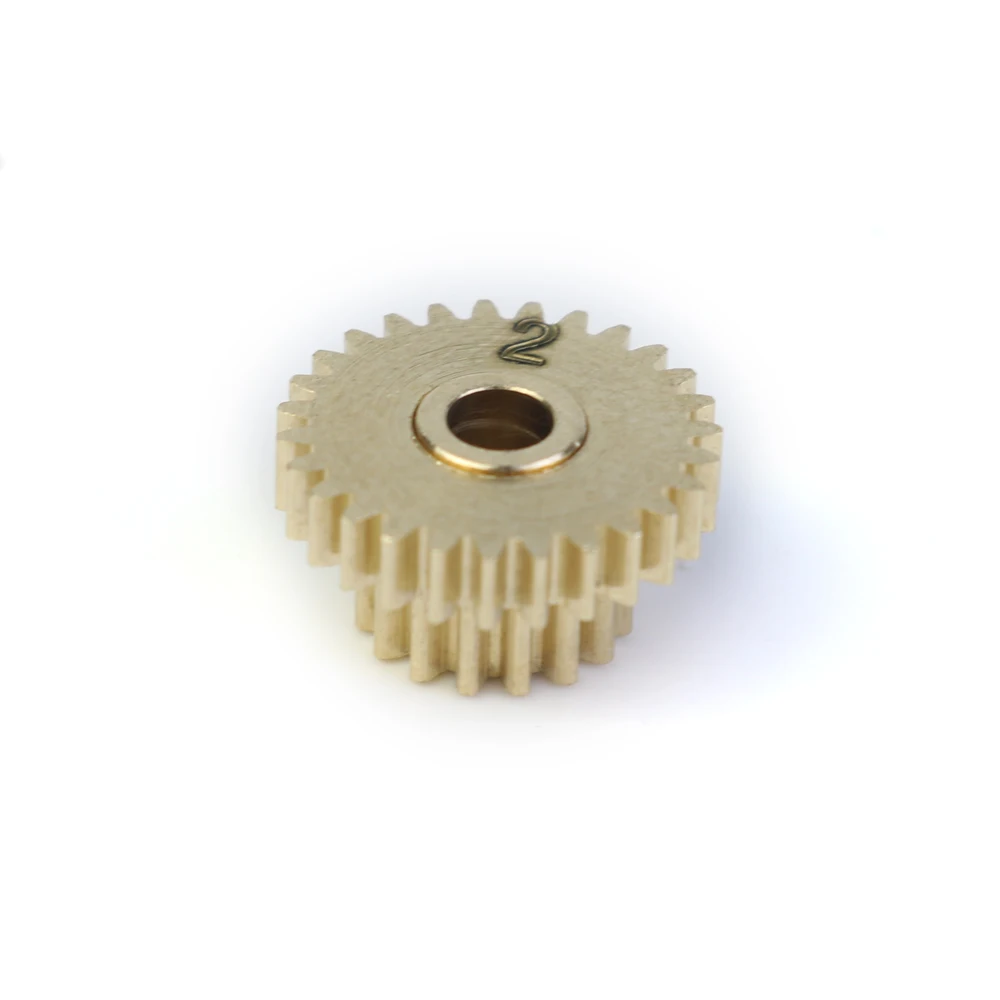

* Դաստին անկյուն: Անկյունը, որով գամբաթները մտցնում են միմյանց հետ, սովորաբար 20° կամ 14.5° ստանդարտ գամբաթների համար:

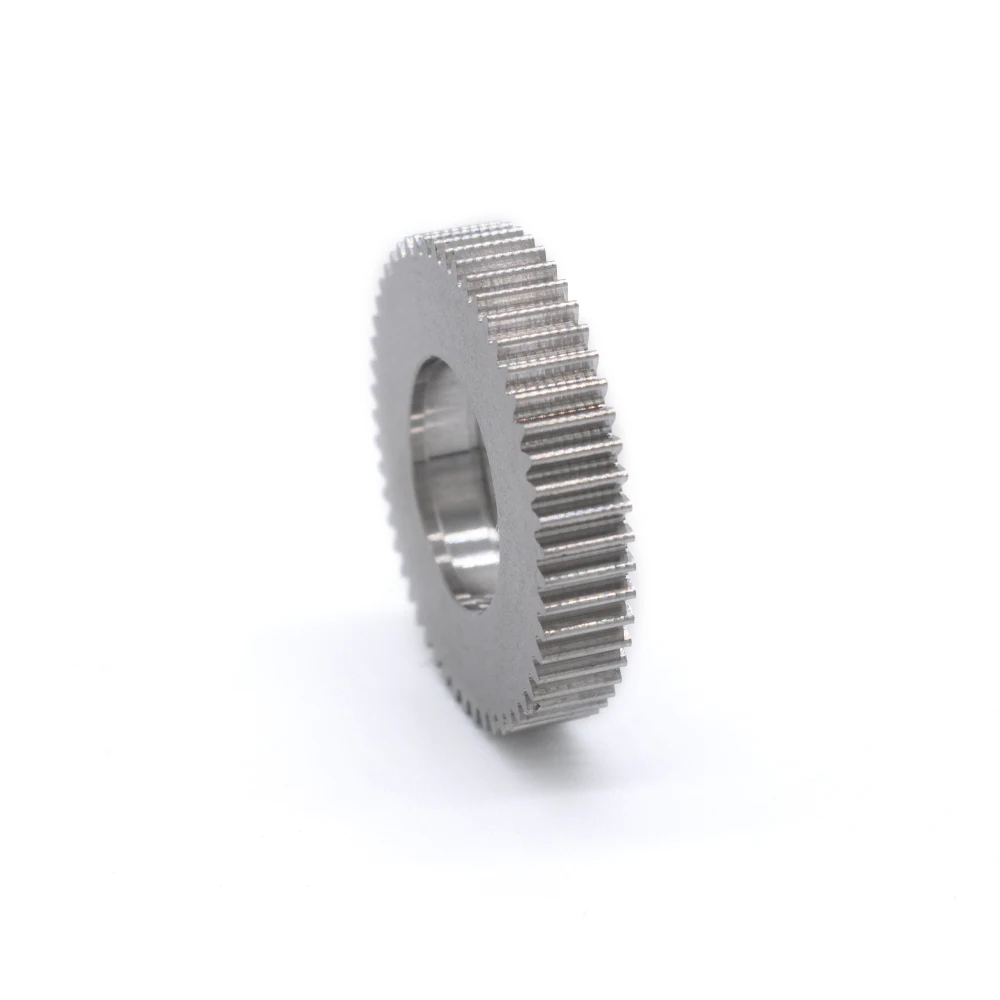

* Հարթ լայնություն: Գամբաթի առանցքի ուղղությամբ գամբաթների լայնությունը:

* Պիչ: Համարների շրջակայքում գտնվող հարևան առանցների միջև հեռավորությունը:

* Դրդուկ և բանավոր չափեր՝ Նշեք ներսում առած արտապատկերի տրամագծի և բանավոր չափերը, որպեսզի համոզվեք, որ ճանապարհի վրա ճիշտ է տեղադրված:

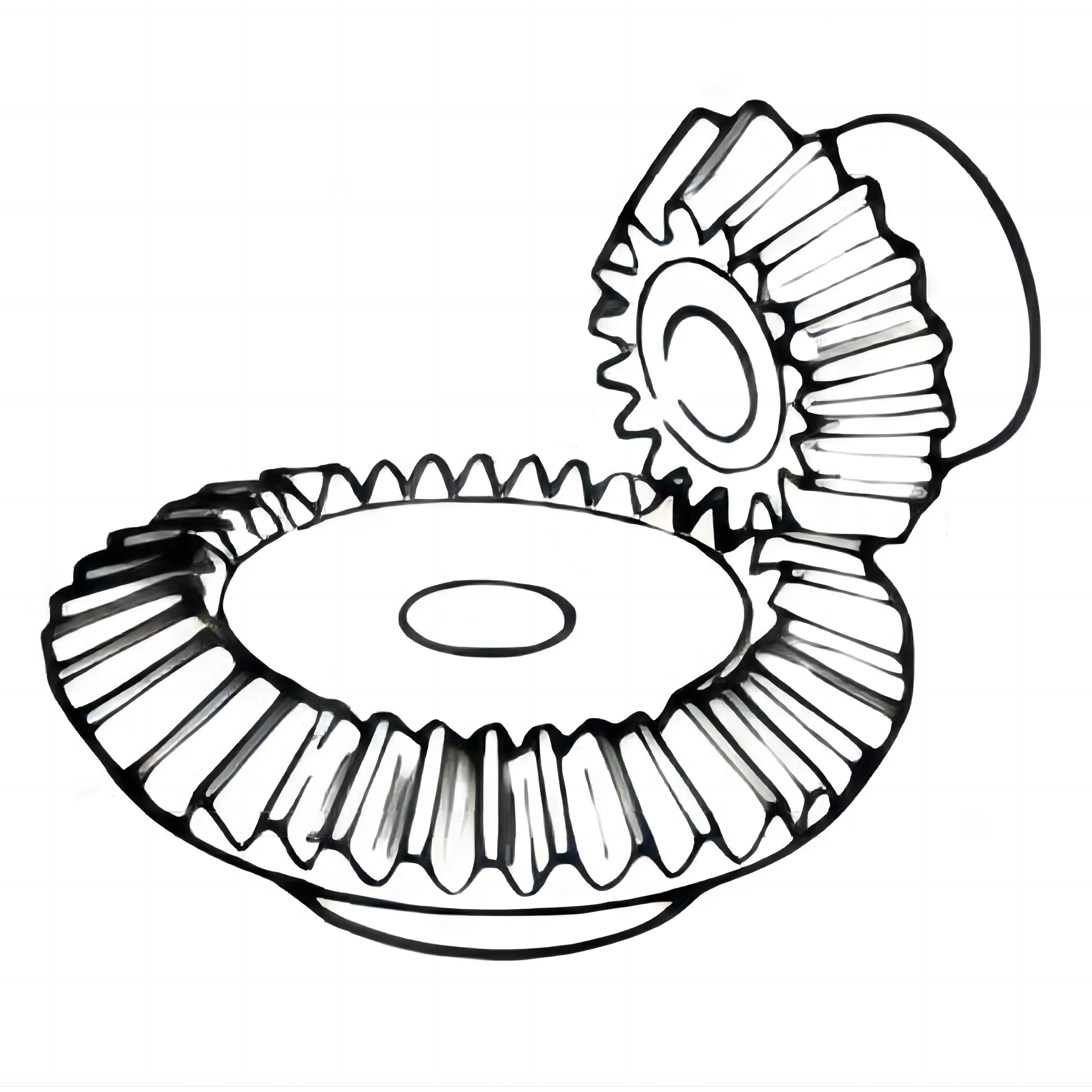

* Արկունիքների քանակ՝ Սա որոշում է չափսերը և գիտաթիվի հարաբերությունը, ազդելով крутящего ուժի և արագության վրա։

* Դաստին անկյուն: Անկյունը, որով գամբաթները մտցնում են միմյանց հետ, սովորաբար 20° կամ 14.5° ստանդարտ գամբաթների համար:

* Հարթ լայնություն: Գամբաթի առանցքի ուղղությամբ գամբաթների լայնությունը:

* Պիչ: Համարների շրջակայքում գտնվող հարևան առանցների միջև հեռավորությունը:

* Դրդուկ և բանավոր չափեր՝ Նշեք ներսում առած արտապատկերի տրամագծի և բանավոր չափերը, որպեսզի համոզվեք, որ ճանապարհի վրա ճիշտ է տեղադրված: