בנייןבנין 49, פארק התעשייה פומין, כפר פינגהו, מחוז לונגנג

יום ראשון סגור

סוג:Broaching, חיתוך, חקיקה / חיתוך כימי, חיתוך לייזר, גילוף, שירותי חיתוך אחרים, סיבוב, Wire EDM,.Prototyping מהיר

מספר מודל:OEM

מילת מפתח:שירותי חיתוך CNC

חומר: פלדה ללא חמצון אלומיניום ספוג נחושת מתכת פלסטיק

שיטה לעיבוד:CNC גילוף

זמן מסירה:7-15 ימים

איכותאיכות:איכותאיכות איכות גבוהה

תעודת זיהוי:ISO9001:2015/ISO13485:2016

כמות מינימלית:1 חלקי

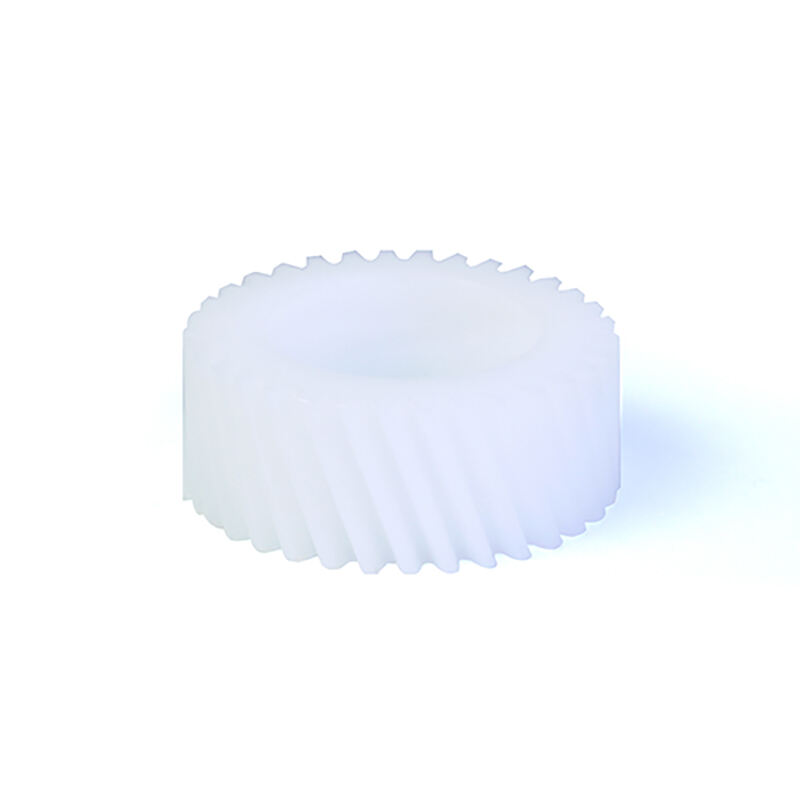

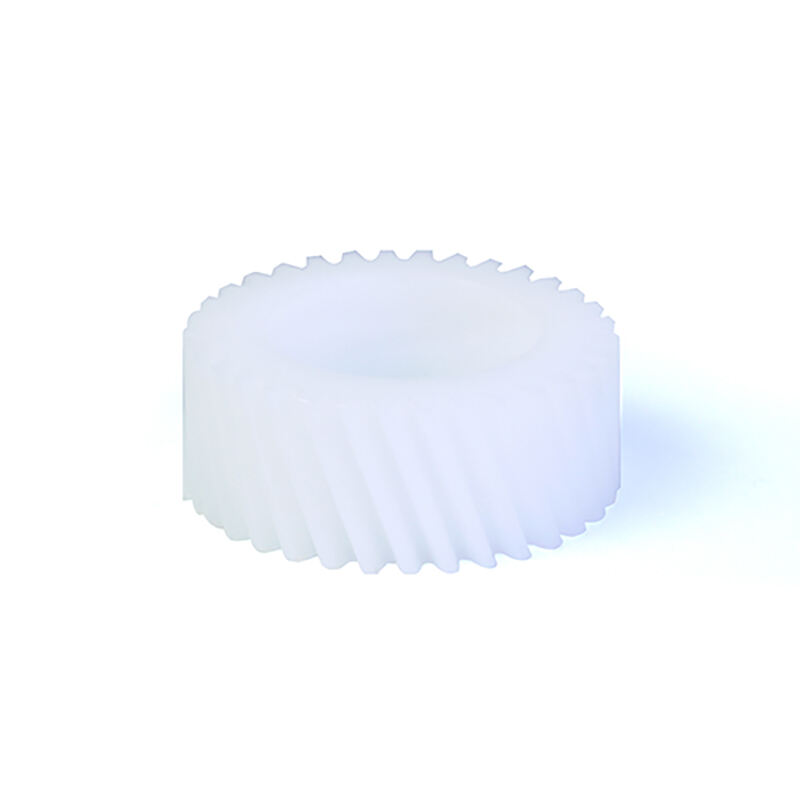

אם אתה מصمם חלקים לתיבת הילוכים חלקה, שקשת ונושאת בלאי, ניילון הוא אולי בדיוק מה שאתה מחפש. ובעבודה עם עיבוד ניילון בנסדרות צמודות, עיבוד עגול הוא אחד מהיעילים והאמינים ביותר

לפני הכל, ניילון אינו רק דבר אחד. זהו סדרת פלסטיק הנדסי, אך עבור גלגיליות, ניילון 66 (PA66) ו ניילון יציקה (PA6) הם הכוכבים הרגילים. הנה למה הם מצוימים בחלקים נעים:

• רטיבות מובנית: זהו הגורם הגדול. לניילון יש מקדם חיכוך נמוך באופן טבעי. הוא חלק מאליו, מה שאומר שהחלקים יכולים להחליק ולהתאים זה לזה עם פחות התנגדות, ובלי צורך תמיד בשמנת או שמן נוסף. זה מאוד חשוב ליישומים נקיים כמו עיבוד מזון או ציוד רפואי.

• חזקים כמו ברזל: זהו חומר hấp absorbציה ושנייה טובה. גלגל שיניים מניילון יכול לעמוד בעצירה מתמדת, התחלות, והפנות שיגרמו לבליטות או סדקים בגלגל שיניים מתכתי.

• תפעול שקט: חומר פלסטי המתאימה עם פלסטיק או מתכת הוא פשוט שקט יותר מאשר מתכת על מתכת. אם אתה מנסה להפחית רעש במבנה שלך, ניילון הוא בחירה נהדרת.

• קל במשקל: המשקל שלו הוא בערך 1/7 ממשקלו של פליז. הקלה על המסה המסתובבת יכולה להוביל לחיסכון באנרגיה ופחות בלאי על רכיבי תמיכה כמו סנאי וצירים.

גירור CNC הינה תהליך ייצור חוסר בו כלי חיתוך נעים לאורך חומר סיבוב. הוא מושלם ליצירת חלקים סימטריים כמו גלגלי שיניים, כפפות, מפרידים, וכמובן, חלקי גלגלים עגולים.

הנה למה עיבוד ב-CNC הינו בחירה חזקה לעיבוד של גלגלי שיניים מניילון:

• דיוק: מכונות CNC יכולות לשמור על סובלנות הדוקות, גם בחומרים רכים כמו ניילון.

• מהירות: ברגע שהתוכנית מותקנת, ניתן לייצר חלקים במהירות ובצורה עקבית.

• חזרתיות: בין אם אתם מייצרים 10 חלקים או 10,000, ה-CNC שומר על אחידות.

• פסול מינימלי: עם מסילות כלי עבודה מותאמות, יש פחות פסול של חומר.

כשאתם עיצוב גלגיליות שיהיו מעוצבות במיכון CNC מפוליאמיד, הנה כמה דברים שחשוב לשים לב אליהם:

• להימנע מקצוות חדים. פוליאמיד זורם טוב יותר עם תכונות פנימיות עגולות, מה שמקטין ריכוזי מתח.

• לקחת בחשבון את ההתפשטות החוםית. פוליאמיד יכול להתרחב יותר ממתכות – להתחשב בכך כשמגדירים טווחי סיבולת.

• להשתמש בתמיכה מתאימה במהלך עיבוד. מאחר שפוליאמיד הוא חומר רך יותר, הוא יכול להישרט. שימוש במנחות יציבות ובכלי חיתוך חדים עוזר למנוע עיוותים או רעידות.

• רכיבי מדפסת תלת מימד

• מכשירים רפואיים

• ציוד לעיבוד מזון

• רובוטיקה ואוטומציה

• מערכות משאבה

אם אתה מصمם מערכת שצריכה תנועה חלקה, שקטה ואמינה, מבלי לשלם ולждול בגלל ייצור מותאם אישית, גלגלי שיניים מנווטים ב-CNC הם פתרון מצוין. הם מציעים שילוב ייחודי של ביצועים, מהירות ודיוק שקשה להתאים לו.

ש: כמה מהר אוכל לקבל מודל CNC?

A: זמני ההמתנה משתנים בהתאם לתלות בקופסא של החלק, זמינות החומר, ובדרישות השלימה, אך באופן כללי:

• דגימות פשוטות: 1–3 ימי עסקים

• פרויקטים מורכבים או עם רכיבים רבים: 5–10 ימי עסקים

שירות מהירה יותר לעתים קרובות זמינה.

Q: אילו קבצי תכנון אני צריך לספק?

A: כדי להתחיל, עליך לשלוח:

• קבצי CAD תלת-ממדיים (עדיף בפורמט STEP, IGES או STL)

• תרשימים דו-ממדיים (PDF או DWG) אם נדרשים ס Tolרנסים מסוימים, חוטים או גימור פני השטח

שאלה: האם אתם יכולים לטפל(tolrances דקיקות?

A: כן. חיתוך CNC הוא האידיאלי כדי להשיג tolerances דקיקות, בדרך כלל בתוך:

• ±0.005" (±0.127 מ"מ) סטנדרטי

• Tolרנסים הדקים יותר זמינים upon request (לדוגמה: ±0.001" או טוב יותר)

שאלה: האם ייצור מודלים CNC מתאים לבדיקת פונקציונליות?

תשובה: כן. מודלים CNC מיוצרים מ质פריטים אמיתיים מתאימים לתכנון מהנדסי, מה שמאירם למשימות של בדיקת פונקציונליות, בדיקת התאמה ובדיקות מכניות.

שאלה: האם אתם מציעים ייצור בשיעורים נמוכים בנוסף למודלים?

א: כן. הרבה שירותים של CNC מספקים ייצור גשר או ייצור בקטנה, מה שמתאים בצורה מושלמת למוצרים במספרים מ-1 ועד כמה מאות יחידות.

ש: האם התכנון שלי הוא סודי?

א: כן. שירותי חטיפי CNC אמינים תמיד חתמים על הסכמי שמירה על סודיות (NDAs) ומטפלים את הקבצים והרכוש האינטלקטואלי שלך בסודיות מלאה.

כל הזכויות הזכויותights שמורות שמורות שזimestecision Producny Ltd. כל הזכויות הימשוחת — מדיניותICY—בלוג