בנייןבנין 49, פארק התעשייה פומין, כפר פינגהו, מחוז לונגנג

יום ראשון סגור

חרבות דיוק

מציגים את השירות להטמעת תבניות עיבוד CNC המופלא על ידי Precision Swords! מוצר זה מוביל בדרגה הגבוהה ביותר נועד לייצור חלקים מדויקים למגוון תחומים כולל תעשיית הרכב תעופה ו więcej. תהליך עיבוד CNC מבטיח שכל חלק יוצר בדיוק עם דיוק אדיר וкаלה.

הטכNICאים המוכשרים שלנו משתמשים במכונות מתקדמות לייצור תבניות שיוצרות חלקים מושלמים בכל פעם. השירות כולל יציקת חרבות דיוק כדורים מתכתיים לרכב עם סוקרנים לתיבת שיניים עמוקה מחומרים מדרגה ראשונה שמבטיחים קיימנות ואריכות טווח.

במפעל Swords Precision ליציקת חלקי CNC, תוכלו לסמוך על כך שהחלקים שלכם יוצרו בדיוק ובמקצועיות. בין אם אתם צריכים הזמנה בודדת ובין אם מדובר בייצור מתמשך, צוות שלנו מחויב לספק מענה לצרכים שלכם ול rebbe את הדרישות שלכם.

הכדורים המתכתיים לרכב שמייצרים בשירות שלנו הם אידיאליים לשימוש במגוון יישומים, החל מחלקי רכב ועד מכשור תעשייתי. תכונת הסוקרן לתיבת שיניים עמוקה מבטיחה חיבור אמין ואינטגרציה חלקה לתוך הפרוייקט שלכם.

Swords Precision מתגאה במתן מוצרים באיכות גבוהה ש rivals לא ניתן בתעשייה. מחויבותנו לאיכות ולאספקה ללקוחות מציבה אותנו בפער מהמתחרים. כשאתה בוחר בשירות שלנו לייצור תבניות בקרת CNC, תוכל להיות tranquilo שאתה מקבל את הטוב ביותר שקיים.

בנוסף למוצרים המובילים שלנו, מציעה Swords Precision מחירים תחרותיים וזמנים קצרים של השלמה. אנו מבינים את חשיבות הישג timely ומשתדלים לספק את החלקים שלך בזמן ובלי פגיעה באיכות.

אם אתה צריך שירותים אמינים ומדויקים לייצור חלקי CNC, אל תחפש הלאה מחברת Swords Precision. מחויבותנו למצוינות ולאספקה ללקוחות הופכת אותנו לבחירה המובילה בכל צרכיך לייצור. סמוך על המומחיות שלנו והנח לנו להגביר את הגרסה שלך לחיים עם שירות הייצור המתקדם שלנו לייצור תבניות בקרת CNC.

עיבוד |

סיבוך CNC, פליז CNC, גזירת לייזר, קיפול, סיבוב, גזירת חוט, דפוס, עיבוד בפריקה חשמלית (EDM), ייצור תבניות, דפוס תלת-מימדי, פרוטוטיפ מהיר, תבניות וכו' |

|||||||

חומרים |

אלומיניום - סדרה 2000, סדרה 6000, 7075, 5052 וכו' |

|||||||

פליז - SUS303, SUS304, SS316, SS316L, 17-4PH וכו' |

||||||||

פליז - 260, C360, H59, H60, H62, H63, H65, H68, H70, برنז, נחושת |

||||||||

טיטניום - דרגה F1-F5 |

||||||||

נירור - אצטל/POM/PA/ניילון/PC/PMMA/PVC/PU/אקריליק/ABS/PTFE/PEEK וכו' |

||||||||

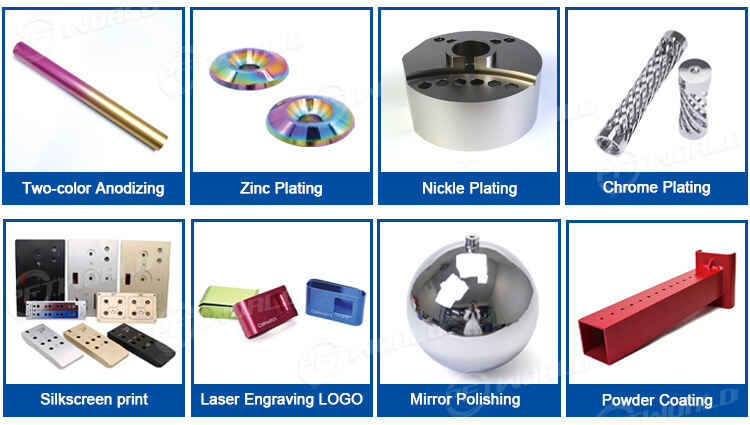

חמצון, סילוק ספוג, מדפסת סריג, ציפוי PVD, ציפוי בزنק/ניקל/כרום/טיטניום, סילוק סריטים, צביעה, ציפוי אבקתי, סילוק חמצון, אלקטרופורזה, גימורי אלקטרו-פוליש, חריצה, לייזר/ וכו'/חריטה וכו' |

||||||||

טיפול שטח |

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/etc/Engrave etc |

|||||||

סובלנות |

+/-0.01 ~ 0.005 מ"מ |

|||||||

ריבוי פני השטח |

Min Ra 0.1~3.2

|

|||||||

תְעוּדָה |

||||||||

עיבוד משטח של חלקים מותכתיים

עיבוד משטח של חלקים מותכתיים כל הזכויות הזכויותights שמורות שמורות שזimestecision Producny Ltd. כל הזכויות הימשוחת — מדיניותICY—בלוג