룽강 구역 핑후 촌, 후민 산업 단지 49동

일요일 휴무

안녕하세요, 모두들! 장난감, 컵 등 플라스틱으로 만들어진 것들을 보고 질문을 작성해 주세요. 그리고 Ask Media Network 또는 Telegram의 Moneycontrol 채널을 통해 우리와 상호 작용하면서 모든 질문을 해결할 수 있습니다. 플라스틱은 일상적으로 널리 사용되며, 그 안정성과 낮은 밀도로 인해 매우 유용합니다. 이들은 주사 성형 공정으로 만들 수 있는 부품들입니다. 이 글에서는 주사 성형 부품에 대한 모든 내용과 다양한 제품 생산에 왜 그렇게 훌륭한지에 대해 다룰 것입니다!

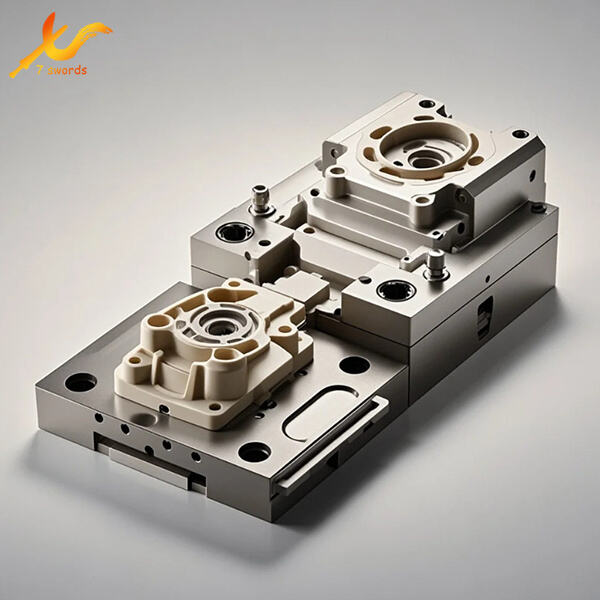

항공 우주 정밀 부품 주사 성형 부품은 주사 성형이라는 제조 공정을 통해 생산되는 독특한 구성 요소입니다. 이 과정이 어떻게 작동하는지 매우 흥미롭습니다! 처음에는 작은 플라스틱 조각인 펠렛이라는 것이 녹아내립니다. 플라스틱을 녹인 후, 이를 금형에 짜거나 분사합니다. 금형은 일반적으로 녹은 플라스틱을 원하는 형태로 유지하는 모양이나 용기입니다. 이 플라스틱이 식으면 굳어져 원하는 물체의 형태로 만들어집니다. 이 공정에는 많은 장점이 있습니다! 첫째, 이는 한 번에 대량의 제품을 매우 빠르게 제작하는 방법입니다 — 공장에 완벽합니다. 둘째, 이 방법으로 제작된 제품은 동일하게 보여서 매우 정확합니다. 모든 장난감 차가 똑같아 보이는 것이 중요하므로 대량 생산할 때 매우 중요한 요소입니다. 또한, 성형된 부품은 튼튼하고 오래 지속되며, 제품에서 계속 사용해도 오랜 시간 동안 유지될 수 있습니다.

그러면 당신은 자신에게 물어볼 수 있습니다. 주사 성형 부품으로 만들 수 있는 것은 무엇일까요? 대답은: 기본적으로 모든 것이라고 할 수 있습니다! 제작할 수 있는 것이 너무 많습니다. 예를 들어, 실제로 우리의 기기를 보호하는 휴대폰 케이스나 차량의 기능을 돕는 자동차 부품 등이 있습니다. 서비스: 주사 성형주사 성형 부품은 이 과정이 매우 다양한 형태로 성형을 가능하게 하기 때문에 다양한 객체를 만들 수 있습니다. 장난감 차나 물병과 같이 가벼운 것을 만들어야 할 때 매우 좋은 선택입니다. 이들은 플라스틱으로 만들어지기 때문에 가볍고 일상 생활에서 쉽게 휴대할 수 있는 아이템으로 사용하기에 적합합니다!

레고를 가지고 놀아본 적 있나요?那是 인기 있는 건축 장난감이고 아이들이 그것을 사랑합니다. 레고 조각들은 주사 성형 부품을 사용하여 제작됩니다. 아마도 당신이 알고 있는 사실일 것입니다. 맞습니다! 모든 레고는 금형을 사용하여 만들어지므로 각 조각은 이전 것과 정확히 같습니다. 이것은 무언가 멋진 것을 만들려면 모든 부품이 맞아떨어져야 한다는 점에서 매우 중요합니다. 이것은 주사 성형 부품의 유연성이 얼마나 큰지를 보여주는 훌륭한 예입니다. 저는 레고가 이 점을 잘 보여준다고 생각합니다. 다양한 모양과 크기로 만들 수 있는 옵션이 있어 마음에 떠오르는 모든 것을 창조할 수 있습니다!

주사 성형 부품의 정말 멋진 특징 중 하나는 금형을 교체하여 다양한 물체를 생산할 수 있다는 것입니다. 예를 들어, 먼저 새 모양의 부품을 성형한 후 녹인 플라스틱을 주입합니다. 그렇게 하면 많은 양의 장난감 새들을 빠르게 만들 수 있습니다. 실제로 같은 기계로 장난감 차량, 컵홀더 심지어 iPhone 케이스(금형만 바꾸면!)도 만들 수 있습니다. 금형을 교체할 수 있는 능력이 바로 주사 성형을 놀라운 제조 공정으로 만드는 요소입니다. 또한, 주사 성형 부품의 정확성 덕분에 다른 방법으로는 어려울 수 있는 매우 복잡한 물체를 만들 수 있습니다. 즉, 새로운 혁신적인 제품을 다양한 방식으로 개발할 수 있다는 의미입니다!

좋은 품질의 제품을 생산하기 위해서는 고품질의 주사 성형 부품이 필요합니다. Swords Precision은 다양한 산업 분야에 걸쳐 고정밀 주사 성형 부품 제조를 전문으로 하며, 거의 모든 용도의 제품을 위한 고객들을 지원합니다. 우리를 통해 제작된 모든 부품은 정밀성, 기술 및 강度로 특징지어집니다. 왜 이것이 중요한가: 보통 구매한 물건이 내구성이 있고 그 역할을 수행하기를 원합니다. 또한 우리는 당신이 자신의 맞춤형 3D 객체를 만들도록 도와드릴 수 있습니다! 아이디어를 실체화된 제품으로 만드는 것은 우리가 도와드릴 수 있는 부분이며, 그것이 다음 베스트셀러 장난감이 될지 아니면 정말 유용할 것이라고 생각하는 기계장치일지 상관없이 가능합니다. 이는 당신이 일상적인 물건들에 대해 Swords Precision을 신뢰할 수 있음을 의미하며, 품질과 내구성 측면에서这是我们가 제공하는 최고의 주사 성형 부품입니다.