룽강 구역 핑후 촌, 후민 산업 단지 49동

일요일 휴무

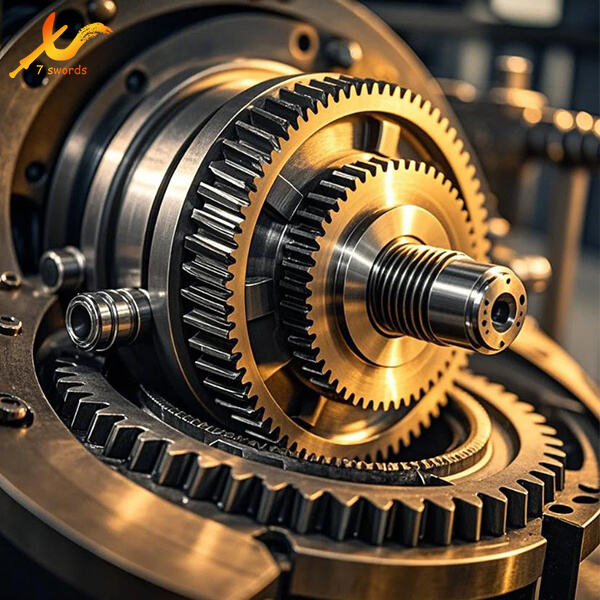

랙은 한쪽 가장자리에 치아가 있는 긴 평평한 금속 조각입니다. 이들은 작은 돌기처럼 보이며, 피니언의 치아와 정확히 맞물리도록 설계되었습니다. 피니언은 치아가 있는 작은 둥근 기어입니다. 피니언이 회전하면 그 치아가 랙의 치아와 맞물려 랙을 앞뒤로 움직입니다. 피니언이 회전할 때,它是 샤프트에 장착되어 있으며 회전할 수 있지만 랙은 움직이지 않습니다. 랙과 피니언은 무언가를 제어하면서 내외로 움직이는 가장 좋은 방법 중 하나입니다. 피니언이 회전하면, 그것은 절대적인 압출물을 앞으로 또는 뒤로 밀어냅니다.

래크 앤 피니언 기어의 또 다른 이점은, 랙 앤 피니언 변환기가 인기를 끄는 주요 요인 중 하나인 그들의 단순성입니다. 그들은 다른 유형의 기어박스 시스템보다 구성 요소가 적어 제작 및 유지보수가 훨씬 더 쉽습니다. 문제가 발생할 경우에도 수리가 더 간단하며, 이러한 단순성은 큰 장점입니다. 또한 랙 앤 피니언 기어는 매우 효율적이고 사용하기 쉬우며, 독특한 설계 덕분에 많은 부품 없이도 전력을 직접 전달할 수 있어 효율성을 유지하면서 에너지를 절약합니다.

알루미늄 CNC 부품 많은 다른 장소와 응용 프로그램에서 사용됩니다. 가장 잘 알려진 곳은 자동차에서 볼 수 있습니다. 차를 조작할 때 랙 앤 피니언은 스티어링 휠의 회전 운동을 바퀴의 직선 운동으로 변환하는 데 도움을 줍니다. 이 시스템은 운전자가 방향을 전환할 때 자동차를 조작하는 데 도움을 줍니다. 자동차 외에도 랙 앤 피니언 기어는 직선으로 움직이는 것을 목적으로 설계된 기계, 로봇공학 및 기타 도구들에 적용됩니다. 특히 매우 정확한 움직임이 필요한 응용 분야에서 유용합니다.

Rack과 pinion을 살펴볼 때-tooth(이빨)의 수는 고려해야 할 또 다른 요소입니다. tooth의 수는 어떤 행성 기어 시스템의 전력 전달 잠재력과 수명에 크게 영향을 미칩니다. 적절한 tooth 수: 각 기어의 tooth 수는 기어들 사이의 관계에 영향을 미칩니다; 잘못된 선택은 부적절한 작동과 조기摩耗를 초래할 수 있습니다. 또한 피치 직경을 고려하는 것이 중요합니다. 이는 rack과 pinion의 tooth가 겹치는 직경입니다. 예상되는 하중을 견딜 수 있도록 피치 직경을 선택하는 것이 필요합니다.

랙과 피니언 기어 고장 진단 일반적인 문제들 랙과 피니언 기어의 고장 진단 시 몇 가지 일반적인 문제가 발생할 수 있습니다. 예를 들어, 윤활이 부족하거나 기어가 과부하 상태에서 사용될 경우 시간이 지나면서 기어의 치아가摩耗하게 됩니다. 마모된 치아는 기어의 수명을 단축시키고, 정확히 맞춰지지 않은 경우 과도한 백래시를 초래합니다(대개 이런 상황이 자주 발생합니다). 또 다른 문제로 기어가 올바르게 정렬되지 않은 경우도 있습니다. 기어가 잘못 맞물리면 소음이 발생하고 효율성이 떨어지며, 특히 여러 개의 기어가 제대로 정렬되지 않으면 더욱 그렇습니다. 과도한 소음의 원인은 다양할 수 있는데, 기어 설계의 오류에서부터 설치 문제까지 포함됩니다.

물론, 랙 앤 피니언 기어는 많은 장점들을 제공하지만 항상 가장 적절한 옵션은 아닙니다. 랙 앤 피니언 기어의 단점 중 하나는 다른 어떤 기어보다 토크 용량이 적다는 것입니다. 토크는 기어가 처리할 수 있는 회전력인데, 주조된 랙 앤 피니언 기어는 이로 인해 더 불리하고 무거운 하중을 다루기 어려운 경우가 있습니다. 이러한 경우에는 웜 기어보다 헬리컬 기어나 비스 기어와 같은 다른 형태의 기어가 더 적합할 수 있습니다.

그들의 이름에서 알 수 있듯이, 헬리컬 기어는 나사산과 유사하게 경사진 치아를 가지고 있어 랙 앤 피니언 스타일의 기어보다 더 부드럽고 조용하게 작동합니다 [13]. 그들은 소음에 민감한 환경에서 자주 사용됩니다. 반면 비스 기어는 서로 각도를 이루며 배치된 샤프트 간에 전력을 전달하도록 설계되었습니다. 그러나 비스 기어는 랙 앤 피니언 기어보다 비쌀 수 있지만 고 토크와 정확한 동작이 필요한 응용 분야에 더 적합합니다.