룽강 구역 핑후 촌, 후민 산업 단지 49동

일요일 휴무

주사 금형은 장난감 및 플라스틱 생산 분야에서 중요한 도구입니다. 이들은 장난감, 병 등 일상 생활에서 사용되는 다양한 물품을 플라스틱으로 성형하는 데 중요한 역할을 합니다. Sword Precision에서는 오래 사용 가능한 고품질의 제품을 제조합니다. 항공 우주 정밀 부품 . 우리는 주사 성형의 유형과 그 다양한 구성 요소에 관련된 측면, 이를 유지하는 방법에 대한 팁, 그리고 특히 작업에 적합한 금형을 선택하는 것이 중요한 이유에 대해 논의할 것입니다.

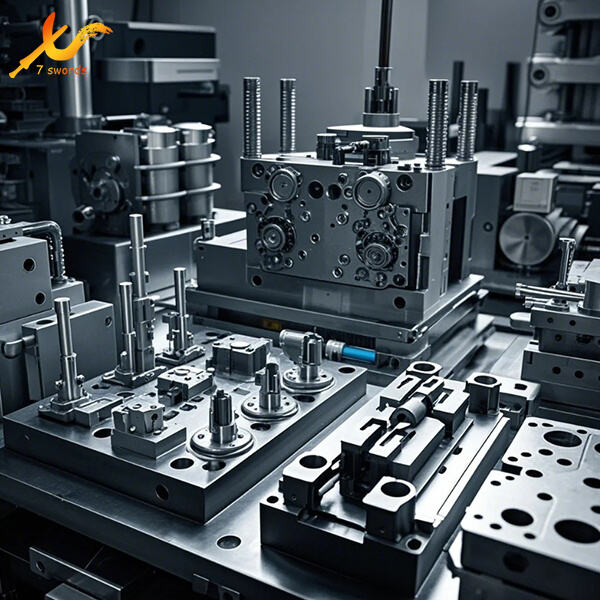

주사 성형 금형은 고압으로 플라스틱 재료를 형성하는 독특한 구조입니다. 따라서 플라스틱은 우리가 원하는 모양을 얻을 수 있도록 힘껏 금형에 밀어 넣습니다. 주사 성형 금형은 완성된 제품을 형성하기 위해 모두 결합되는 여러 구성 요소로 구성됩니다. 이러한 금형은 자동차 제조, 의료 기기 및 장난감 생산 등 다양한 산업에서 사용됩니다. 이들은 생산 과정의 필수적인 부분을 이루며, 우리가 보고 일상 생활에서 사용하는 제품을 가능하게 합니다.

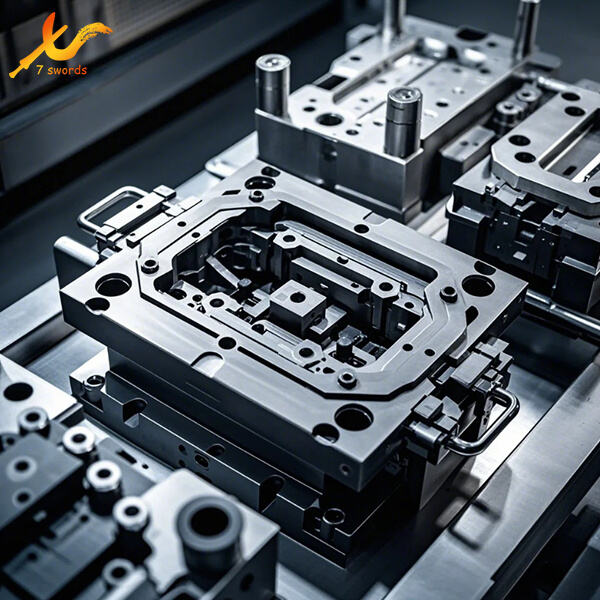

주사 성형 금형은 적절히 작동할 수 있도록 많은 구성 요소와 부품으로 구성됩니다. 첫 번째는 cavity(강)라고 불리며, 여기에 플라스틱이 주입되어 형태를 취하게 됩니다. 두 번째 부분은 core(심)로 불리며, 이 부분에서 플라스틱이 최종 형태로 성형됩니다. 추가적인 구성 요소로는 플라스틱이 금형으로 들어오는 곳인 sprue(주입구)와 플라스틱을 cavity로 안내하는 runner(유도로)가 있습니다. 또한 냉각된 금형에서 최종 제품을 제거하는 데 도움을 주는 ejector pins(추출 핀)도 있습니다. 모든 부품은 금형이 올바르게 작동하고 양질의 제품을 얻도록 하는데 중요합니다.

적절한 유지 알루미늄 CNC 부품 최적의 상태를 유지하고 더 오래 사용할 수 있도록 하는 것이 중요합니다. 또한 적절히 관리함으로써 금형의 품질이 떨어지는 문제를 피할 수 있습니다. 금형을 관리하는 최고의 방법 중 하나는 정기적으로 손상이나摩耗의 징후를 확인하는 것입니다. 고품질의 금형을 선택하려면 균열, 울퉁불퉁한 부분 또는 금형 사용에 문제가 될 수 있는 다른 문제를 확인해야 합니다. 추가 팁으로는 먼지나 이물질로 인한 문제를 방지하기 위해 금형을 깨끗이 유지하고, 움직이는 부품에 윤활유를 발라 원활한 동작을 보장하며, 즉시 고장난 부품을 교체하는 것입니다. Swords Precision은 최고 품질의 금형만 제작하여 장인들이 오랫동안 사용할 수 있도록 합니다. 또한 고객들이 금형을 최상의 상태로 유지하고 고품질의 제품을 계속 생산할 수 있도록 유지보수 서비스도 제공됩니다.

강력한 최종 제품 품질을 얻기 위한 가장 중요한 요소 중 하나는 올바른 주사 성형 모를 선택하는 것입니다. 모는 생성하려는 제품의 정확한 요구 사항에 맞게 커스터마이징되어야 하며, 크기와 형태 측면에서 적합해야 합니다. 스워드 프리시전은 고객들과 함께 그들의 요구사항에 정확히 부합하는 커스텀 몰드를 개발하기 위해 노력합니다. 또한 강철이나 알루미늄과 같은 다양한 종류의 몰드 재료를 선택할 수 있으며, 평생 사용 가능한 (10년 이상) 견고한 재료의 몰드나 가벼운 무게지만 고용량 및 실용적인 목적의 몰드를 선택할 수도 있습니다. 이를 통해 고객들은 자사 제품에 가장 적합한 솔루션을 선택할 수 있게 됩니다.

현대 주사 성형 금형의 품질과 효율성은 과거의 새로운 아이디어와 기술에 의해 변화됩니다. 이것이 바로 Sword Precision에서 가장 선진적인 기술로 금형을 설계하고 제조하는 이유입니다. 이는 우리가 제품을 제공하는 방식을 개선하고 고객을 더 잘 지원할 수 있는 방법을 지속적으로 검토하는 것을 의미합니다. 또한, 우리는 고객들이 시장에서 최고급 도구를 사용할 수 있도록 산업 발전에 앞서 나갑니다. 우리의 전문가들은 고객의 개별 요구에 맞춘 시장에서 최고의 솔루션을 제공하기 위해 노력하며, 이를 통해 고객들이 조직에서 더 높은 성능을 발휘할 수 있도록 돕습니다.