룽강 구역 핑후 촌, 후민 산업 단지 49동

일요일 휴무

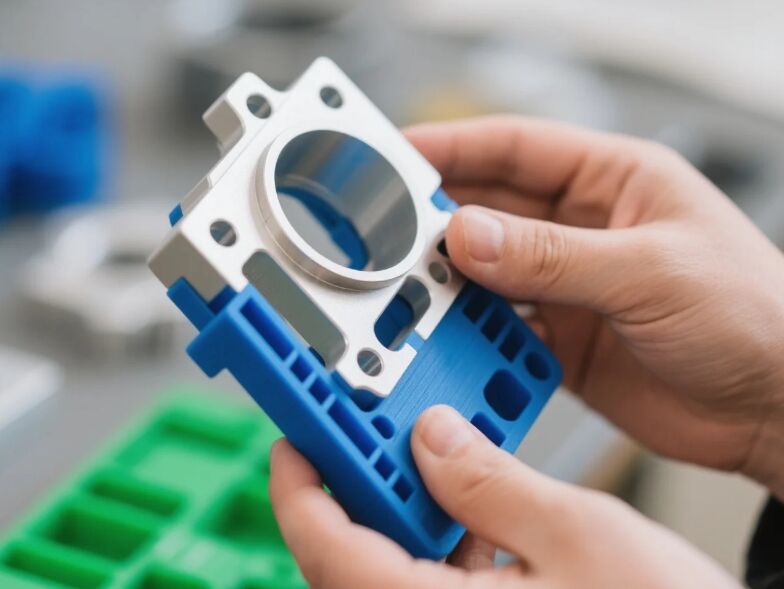

안녕하세요! 만약 당신이 맞춤형 알루미늄과 플라스틱 빠른 프로토타입 품질을 저하시키지 않고 번개처럼 빠르게 받고 싶다면, 올바른 곳에 도착했습니다. PFT , 우리는 최신 기술을 장인정신과 결합하여 여러분의 아이디어를 구체적인 결과로 만들어냅니다.

선진 생산 기술

우리는 운영합니다 CNC 머신 센터 (5축 정밀 가공), 산업용 3D 프린터 (SLA, SLS), 그리고 주사 성형 시스템 복잡한 기하학적 구조를 처리할 수 있습니다. 우리의 기계는 오차 범위를 최소화하여 ±0.01mm – 항공 우주, 자동차, 또는 의료용 프로토타입에 적합합니다.

타협 없는 품질

모든 프로토타입은 3단계 검사 를 거칩니다: 재료 확인, 치수 정확도 점검 및 기능 테스트. 우리의 ISO 9001 인증된 프로세스 일관성을 보장하며, XRF 분석기 가 재료의 완전성을 검증합니다.

모든 필요에 맞는 소재

에서 우주 항공 등급 알루미늄 6061 ~까지 의료 규격 준수 ABS 그리고 자외선에 강한 폴리카보네이트 , 우리는 50종 이상의 소재를 재고로 유지하고 있습니다. 필요하십니까 과형 또는 금속-플라스틱 하이브리드 ? 이미 제작했습니다.

기한을 앞당기는 속도

대부분의 주문은 3~5 일 일 이내 출고됩니다. 급박합니까? 우리의 24/7 빠른 툴링 팀이 추가 요금 없이 급한 작업을 처리합니다. 지난달에 92%의 고객들이 부품을 받았습니다 이전 그들의 예정된 날짜에.

종합 지원

에서 무료 DFM 피드백 ~까지 배송 후 세부 조정 , 우리는 파트너입니다 - 단순한 공급자가 아닙니다. 우리의 엔지니어들은 맞춤, 스트레스 포인트 또는 표면 마감 문제를 해결할 것입니다 - 당신을 위해.

“[Your Factory Name]과 협력하면서 제품 출시 일정을 40% 단축할 수 있었습니다. 그들의 빠른 회전 그리고 제조를 위한 설계 노트 로 인해 비용이 많이 드는 재설계를 방지했습니다.”

– Sarah K., 주임 엔지니어

60초 안에 견적 요청하기 [ 당신의웹사이트.com ] 또는 프로토타입 팀으로 전화 주세요 [ +86 18926459278 ]. 첫 번째 고객은 10% 할인 50개 이상 주문 시 할인 혜택!

가공 |

CNC 터닝, CNC 밀링, 레이저 절단, 벤딩, 스피닝, 와이어 절단, 압출 성형, 전기 방전 가공 (EDM), 주사성형 |

|||

재료 |

알루미늄: 2000 시리즈, 6000 시리즈, 7075, 5052 등 |

|||

스테인리스: SUS303, SUS304, SS316, SS316L, 17-4PH 등. | ||||

강철: 1214l/1215/1045/4140/scm440/40crmo 등 | ||||

청동: 260, c360, h59, h60, h62, h63, h65, h68, h70, 청동, 구리 | ||||

티타늄: F1-F5급 | ||||

플라스틱: 아세탈/포름/파/나일론/PC/PMMA/PVC/PU/아크릴/abs/ptfe/피크 등 | ||||

표면 처리 |

아노다이징, 비드 블래스트, 실크스크린, PVD 도금, 아연/니켈/크롬/티타늄 도금, 문질러짐, 도장, 분말도장, 패시베이션, 전기泳, 전기 연마, 난입자, 레이저/에칭/각인 등. |

|||

공차 |

±0.002 ~ ±0.005mm |

|||

표면 거칠기 |

미나 0.1~3.2 |

|||