Pastatas 49, Fumin pramoninis parkas, Pinghu kaimas, Longgang rajonas

Sekmadienis Uždaryta

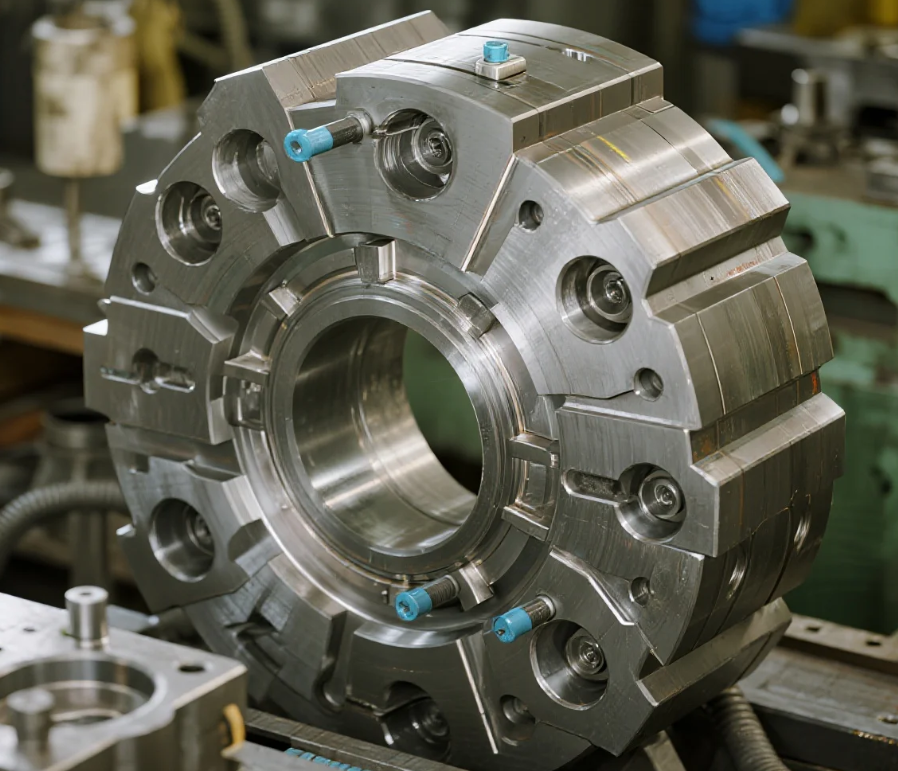

Individualios formos padeda iš produkto idėjų sukurti pakartojamas, aukštos kokybės dalis. Nepriklausomai nuo to, ar jums reikia vienos prototipinės ertmės, ar keturių ertmių gamybos įrankio injekciniam, kompresiniam ar pučiamajam formavimui, tiksli forma ir tikslus gamybos procesas lemia detalės našumą, kainą ir rinkai pateikimo laiką. Šiame straipsnyje paaiškinamas mūsų visapusiškas procesas (DFM, prototipavimas, patvirtinimas, gamyba), pateikiamas anoniminis atvejo tyrimas su matuotais bandymų duomenimis ir pateikiama SEO draugiška turinio struktūra, atsakanti į dažniausius pirkėjų užklausimus: „Kaip“, „Pirkti“ ir „Peržiūrėti/Palyginti“.

Tolerancijų kontrolė ir matmenų stabilumas

Medžiagos srautas (įleidimas, kanalai, išmetimas) siekiant išvengti nepilno užpildymo/deformacijos

Įpurškimo/kompresijos ciklo optimizavimas, kad būtų sumažintas ciklo laikas ir atliekos

Mažesnės detalės savikaina didelėmis apimtimis

Sumažintas surinkimo perdarbas ir garantiniai reikalavimai

Greitesni pirmojo bandymo teisingi paleidimai

(Informacinis tikslas — apima veiksmingus veiksmus ir tai, ko ieško pirkėjai.)

Reikalavimų ir specifikacijų nustatymas

Patvirtinti detalės funkciją, taikinio polimerą/metalą, paviršiaus apdorojimą, numatomą kiekį ir ciklo trukmę.

Gamintojiškumo projektavimo (DFM) peržiūra

Detalės ir formos pasiūlymų projektai (2–3 iteracijos). Pagrindiniai patikrinimai: sienelių storis, nuolydis, ribos, atbuli, tarpai, tolerancijos.

Prototipinė įranga ir greita patvirtinimo procedūra

Aliumininė arba minkšto plieno prototipinė forma, 10–500 detalių montažui/forma/funkcijai tikrinti.

Gamybinė įranga ir bandomasis paleidimas

Kietinamas plieno forma, pilnas bandomasis paleidimas; gaminami pavyzdžiai, matuojami kritiniai matmenys, atliekami mechaniniai bandymai.

Kokybės kontrolė ir proceso kvalifikavimas

Sukuriamas kontrolės planas ir SPC diagramos; pateikiami apžiūros ataskaitos (CMM, vizualiniai, funkciniai bandymai).

Masinė gamyba ir nuolatinis tobulėjimas

Optimizuoti ciklo trukmę, darbo našumą, prevencinio techninio aptarnavimo grafiką.

Klientas: Automobilių jutiklio korpusas (PA66 GF30), 2-formos ertmės plieninė forma.

Tikslas: Sumažinti iškrypimą ir pasiekti pirmo bandymo kokybę >95 % esant tikslinei ciklo trukmei ≤28 s.

Atlikti veiksmai

DFM sumažino vietinę sienelės storį nuo 2,5 mm iki 2,0 mm problemiškose pertvarose.

Įleidimo vieta perkelta nuo krašto į centrą, kad būtų pagerinta tekėjimo pusiausvyra.

Pridėtas šalto gabalo šulinys ir optimizuotas vėdinimas.

Išmatuoti rezultatai

Pirmo bandymo kokybė: 98.2%(palyginus su 86,5 % iki pokyčių)

Vidutinis ciklo laikas: 26,5 s (mažiau nei 34 s)

Matmenų Cpk pagal 3 kritines dimensijas: ≥1.67per 500 pavyzdžių

Perdarinėjimo dažnis: <0.5%

Pastabos: pavyzdžių dydžiai, matavimo metodai ir tikrinimo priemonės (CMM su 2 µm skyra) dokumentuojami bandomajame pranešime, pateikiamame kartu su pristatymu.

Įrankių plienai: P20, H13, S136, 1.2344 — nurodykite pagal dilimo atsparumą, poliravimo poreikį ir gamybos apimtį.

Paviršiaus apdorojimas: SPI A/B blizgiems detalėms, reljefiniai paviršiai su pateiktais pavyzdžiais.

Standartinės tolerancijos: ±0,05 mm daugumai termoplastinių detalių; tikslesnės tolerancijos pasiekiamos po formavimo apdorojant mašinų įrenginiuose, jei reikia.

Tikrinimas: ISO 2859 atrankos metodas, CMM ataskaitos, funkcionalieji bandymai.

Prototipinė aliuminio forma: paprastai gaminama per 7–14 darbo dienų; formos kaina priklauso nuo kamerų skaičiaus ir sudėtingumo.

Kietinamojo plieno serijinė forma: paprastai gaminama per 6–10 savaičių, priklausomai nuo sudėtingumo ir plieno pristatymo laiko.

Kainų veiksniai: lizdų skaičius, plieno rūšis, įpjovos, numatomas tarnavimo laikas (×100 tūkst. iki milijonų), EDM/tikslumo paviršiaus reikalavimai.

Įtraukite atskirų pozicijų kainas: įrankių gamyba, patvirtinimas, bandymo paleidimas ir vieno gaminio gamybos kaina nurodytu apimtimi.

Autorių teisės © Shenzhen Perfect Precision Products Co., Ltd. Visos teisės saugomos — Privatumo politika—Tinklaraštis