Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

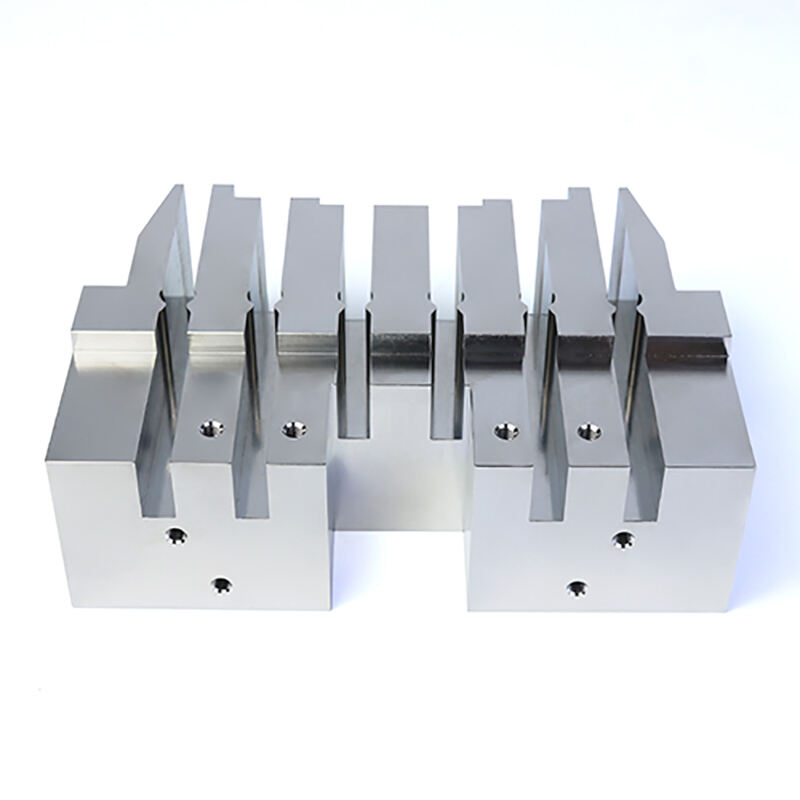

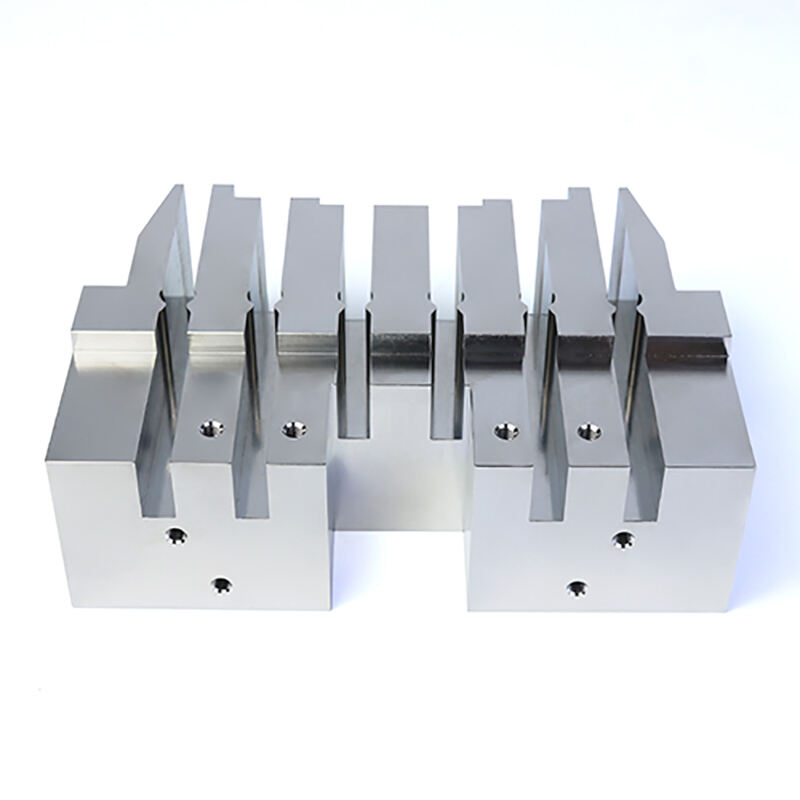

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Model Number:OEM

Keyword:CNC Machining Services

Material:stainless steel aluminum alloy brass metal plastic

Processing method :CNC milling

Delivery time:7-15 days

Quality:High End Quality

Certification:ISO9001:2015/ISO13485:2016

MOQ:1Pieces

The medical industry demands an exceptional level of precision, consistency, and reliability — especially when it comes to the manufacture of medical components. This is where Medical CNC parts play a vital role. Using Computer Numerical Control (CNC) machining, manufacturers can produce highly precise medical components that meet rigorous industry standards. From surgical tools to implantable devices, CNC machining is the backbone of modern medical manufacturing.

Medical CNC parts are components manufactured using CNC machining techniques specifically for medical applications. These parts can include surgical instruments, orthopedic implants, prosthetic components, dental tools, and even specialized parts for diagnostic equipment.

CNC machining allows these components to be made from high-grade materials such as titanium, stainless steel, medical-grade plastics (like PEEK and PTFE), and cobalt-chrome alloys — all of which are critical for biocompatibility, durability, and corrosion resistance.

Medical devices and tools often come with strict dimensional tolerances, surface finish requirements, and complex geometries. CNC machining provides a solution with:

• Unmatched Precision: Micron-level tolerances are achievable, ensuring tight fits and functional integrity.

• Repeatability: Critical for mass production of parts that must perform identically in every application.

• Design Flexibility: Rapid prototyping and complex geometries are easier to execute with 3-, 4-, and 5-axis CNC machines.

• Material Versatility: CNC machines can handle a broad range of biocompatible materials required in the medical field.

• Regulatory Compliance: CNC machining processes can be controlled and validated to meet FDA and ISO 13485 standards.

1.Orthopedic Implants

Includes items such as knee and hip joint replacements, spinal rods, and bone plates. These are often machined from titanium alloys due to their strength, lightness, and compatibility with human tissue.

2.Surgical Instruments

Forceps, scalpels, retractors, clamps, and drill guides must be precise and sterilizable. CNC machining provides the accuracy and surface finish needed for these tools to function in critical environments.

3.Dental Components

Dental abutments, crowns, bridges, and surgical guides are increasingly made using CNC milling machines, ensuring a perfect fit for individual patients.

4.Prosthetic Components

CNC-machined prosthetics are designed to match the unique anatomy of a patient, often using custom scans and CAD models.

5.Device Housings and Fixtures

Medical imaging and diagnostic equipment rely on precise mechanical components and structural housings, often made from aluminum or medical plastics.

• Titanium (Ti-6Al-4V): Extremely biocompatible, corrosion-resistant, and strong, making it ideal for implants.

• Stainless Steel (316L): Used widely for tools and implants; it is durable and resists rust and corrosion.

• Cobalt-Chrome Alloys: Common in orthopedic and dental implants due to their hardness and wear resistance.

• PEEK (Polyether ether ketone): A high-performance thermoplastic used in spinal implants and surgical instruments.

• PTFE (Teflon): Chemically resistant and used in applications requiring lubrication-free parts.

• 5-Axis CNC Machining: Allows for the production of complex parts with fewer setups and tighter tolerances.

• Swiss Machining: Perfect for small, high-precision parts like bone screws and pins.

• Micro Machining: Enables the creation of miniature features down to microns, essential for components like catheter tips or sensor housings.

• Wire EDM (Electrical Discharge Machining): Used for intricate cuts and fine finishes on hard metals.

Q:How fast can I receive a CNC prototype?

A:Lead times vary depending on part complexity, material availability, and finishing requirements, but generally:

• Simple prototypes: 1–3 business days

• Complex or multi-part projects: 5–10 business days

Expedited service is often available.

Q:What design files do I need to provide?

A:To get started, you should submit:

• 3D CAD files (preferably in STEP, IGES, or STL format)

• 2D drawings (PDF or DWG) if specific tolerances, threads, or surface finishes are required

Q:Can you handle tight tolerances?

A:Yes. CNC machining is ideal for achieving tight tolerances, typically within:

• ±0.005" (±0.127 mm) standard

• Tighter tolerances available upon request (e.g., ±0.001" or better)

Q:Is CNC prototyping suitable for functional testing?

A:Yes. CNC prototypes are made from real engineering-grade materials, making them ideal for functional testing, fit checks, and mechanical evaluations.

Q:Do you offer low-volume production in addition to prototypes?

A:Yes. Many CNC services provide bridge production or low-volume manufacturing, ideal for quantities from 1 to several hundred units.

Q:Is my design confidential?

A:Yes. Reputable CNC prototype services always sign Non-Disclosure Agreements (NDAs) and treat your files and intellectual property with full confidentiality.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog