Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

When you hear the steady clamp, inject, cool, release cycle inside a molding workshop, you know parts are being born in seconds. But what if you don’t have direct access to a factory floor? Today, online injection molding services bridge that gap, allowing engineers, buyers, and startups to order molded parts from their laptops—without compromising speed, quality, or cost transparency.

Mould injection molding is a high-efficiency manufacturing process that injects molten plastic into a steel or aluminum mold, producing parts with precise dimensions and repeatable consistency.

Applications: automotive components, consumer electronics, industrial housings, and medical devices.

Advantages: scalability (from prototypes to millions of units), material versatility, and cost efficiency at high volumes.

Traditional sourcing requires multiple factory visits and long communication chains. Online platforms simplify this by offering:

Instant quoting systems – Upload a CAD file and receive pricing in minutes.

Material databases – Select from ABS, PP, PC, nylon, or reinforced plastics.

DFM feedback – Get automated design-for-manufacturability checks to avoid defects like sink marks or warping.

Global supplier networks – Match with certified factories near your market to cut lead time.

? Example: A European startup reduced their tooling lead time from 6 weeks to 10 days using an online injection molding partner with pre-hardened steel tooling options.

Step 1 – Upload CAD file

You submit 3D models (.STEP, .IGS, .STL).

Step 2 – Automated analysis

The system checks draft angles, wall thickness, and undercuts.

Step 3 – Instant quote & material selection

Pricing includes tooling cost + per-unit cost breakdown.

Step 4 – Tooling & sampling

Prototype mold made in aluminum or steel. T1 samples shipped for approval.

Step 5 – Mass production & delivery

After approval, scaling to 100–1,000,000+ units.

Buyers often ask: “How much does it cost to get plastic parts molded online?”

Here’s what influences pricing:

| Factor | Description | Impact on Cost |

|---|---|---|

| Tooling material | Aluminum vs. hardened steel | Steel molds cost 2–3× more but last longer |

| Part complexity | Undercuts, fine textures, inserts | Higher machining time = higher price |

| Order volume | Small runs vs. mass production | Unit price drops by 70%+ at scale |

| Material choice | Commodity vs. engineering plastics | Specialty resins add 15–40% |

| Surface finish | Polished, textured, painted | Adds secondary processing costs |

? Pro tip: For prototyping or low-volume runs, choose aluminum tooling—cheaper upfront and faster to machine.

Use Online Services if:

You need fast quoting and short-run production.

You want global supplier access.

Your team works remotely and needs digital project management.

Use Local Shops if:

You require frequent on-site visits.

You need highly specialized or proprietary molds.

Logistics cost outweighs online convenience.

To evaluate online platforms, we compared three top providers:

| Platform | Strengths | Best For |

|---|---|---|

| Xometry | Large supplier network, instant quoting | Fast global prototyping |

| Protolabs | Ultra-quick lead times (1–15 days) | Low-volume functional parts |

| Fictiv | Strong DFM feedback, flexible order size | Iterative product design |

Q1: What is the minimum order quantity (MOQ) for online injection molding?

Most services support as low as 50–100 parts using rapid tooling.

Q2: How long does it take to receive first samples?

With aluminum molds, T1 samples can ship in 7–10 business days.

Q3: Can online suppliers guarantee quality?

Yes. Reputable services offer ISO 9001-certified factories, CMM reports, and first article inspection (FAI).

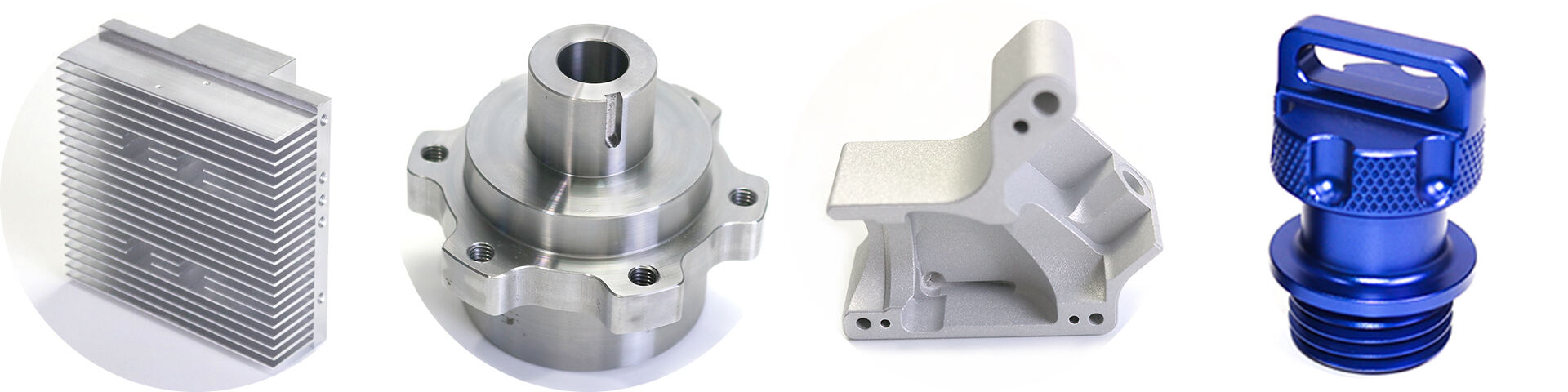

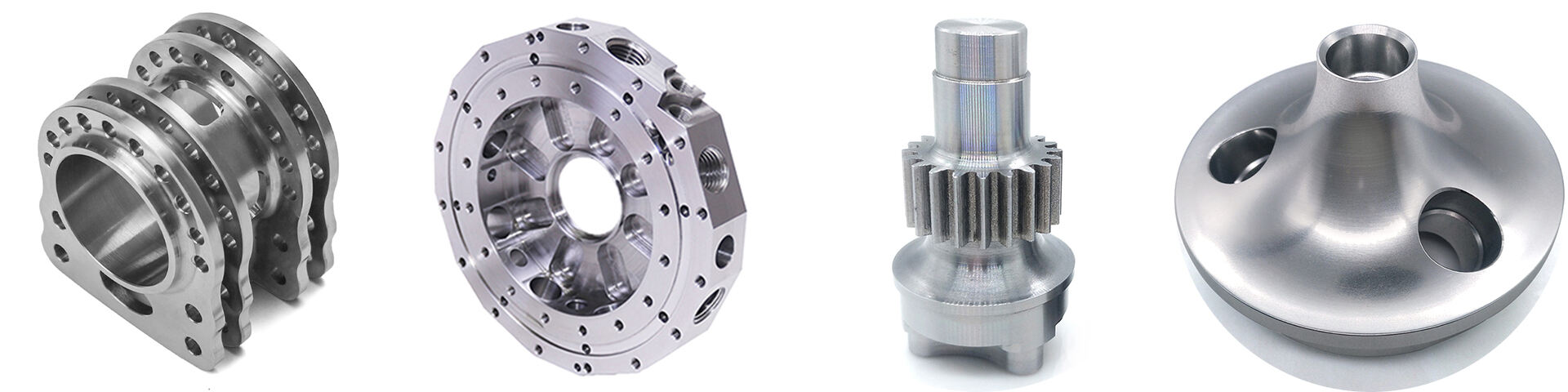

7 Swords Precision: Your Trusted Partner in Custom CNC Machining

As a leading provider of custom CNC machining parts and components, 7 Swords Precision specializes in prototype turning and milling using high-quality metal materials. We deliver precision-engineered products tailored to the unique requirements of various industries. Our commitment to excellence has established us as one of the top CNC manufacturing suppliers in the market.

We are proud to hold several production certificates for our CNC machining services, which demonstrates our commitment to quality and customer satisfaction. Our team follows strict quality control procedures to ensure that every part we produce meets the highest standards of quality and accuracy

Processing |

CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding |

|||||||

Materials |

Aluminum: 2000 series, 6000 series, 7075, 5052, etc |

|||||||

Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc |

||||||||

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc |

||||||||

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

||||||||

Titanium: Grade F1-F5 |

||||||||

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc |

||||||||

Surface Treatment |

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc |

|||||||

Tolerance |

±0.002 ~ ±0.005mm |

|||||||

Surface Roughness |

Min Ra 0.1~3.2

|

|||||||

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog