Gebouw 49, Fumin Industrieel Park, Pinghu Village, Longgang District

Zondag gesloten

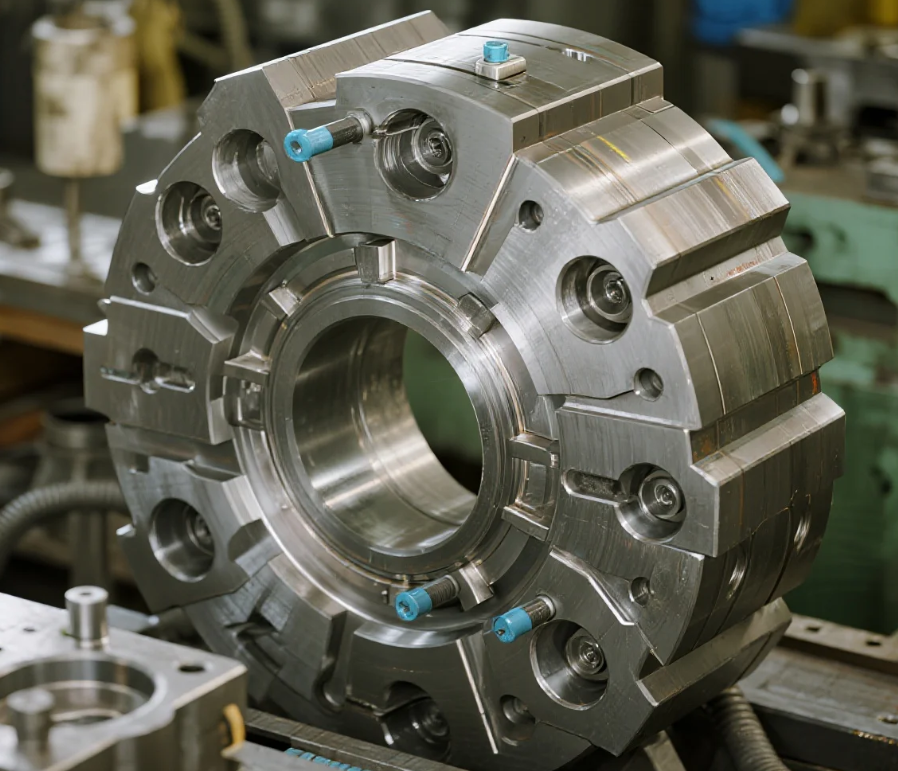

Aangepaste matrijzen zorgen ervoor dat productideeën kunnen worden omgezet in reproduceerbare, hoogwaardige onderdelen. Of u nu een enkele prototypematrijs nodig heeft of een productiematrijs met vier holtes voor spuitgieten, persvormen of blaasvormen: betrouwbaar matrijzontwerp en precisiefabricage bepalen de prestaties, kosten en time-to-market van het onderdeel. In dit artikel wordt ons end-to-end-proces uitgelegd (DFM, prototyping, validatie, productie), wordt een geanonimiseerde casestudy met gemeten testdata getoond en wordt een SEO-vriendelijke inhoudsstructuur geboden die veelvoorkomende vragen van kopers beantwoordt: "Hoe doe je", "Kopen" en "Beoordelen/Vergelijken".

Tolerantiebeheersing en dimensionale stabiliteit

Materiaalstroom (gietopening, loper, ontluchting) om kortsluitingen/vervorming te voorkomen

Optimalisatie van injectie/compressiecyclus om cyclusduur en afval te verminderen

Lagere kosten per onderdeel bij grootschalige productie

Minder nabewerking bij montage en minder garantieclaims

Snellere succesvolle lanceringen bij de eerste poging

(Informatiedoel — inclusief concrete stappen en wat kopers zoeken.)

Vereisten en specificatie vastleggen

Bevestig onderdelfunctie, doelpolymeer/metaal, oppervlakteafwerking, geschatte hoeveelheid en cyclusduur.

Ontwerp voor fabricage (DFM) beoordeling

Conceptonderdelen en matrijzenvoorstellen opstellen (2–3 iteraties). Belangrijkste controles: wanddikte, uittrekhelling, ribben, versterkingsnokken, toleranties.

Prototype-matrijzen en snelle validatie

Aluminium of zachtstaal prototype-matrijs, 10–500 onderdelen voor pasvorm-/vorm-/functietests.

Productiematrijzen en proefproductie

Geharde stalen matrijs, volledige proef; monsterproductie, meten van kritieke afmetingen, mechanische tests uitvoeren.

Kwaliteitscontrole en proceskwalificatie

Controleplan en SPC-grafieken opstellen; inspectierapporten leveren (CMM, visuele en functionele tests).

Volumeproductie en continue verbetering

Optimaliseer cyclus tijden, doorlooptijdplanning, schema voor preventief onderhoud.

Klant: Auto sensors behuizing (PA66 GF30), 2-caviteit stalen matrijs.

Doelstelling: Verminder vervorming en bereik een eerste-doorloop rendement >95% bij doelcyclus tijd ≤28 s.

Uitgevoerde acties

DFM verlaagde lokale wanddikte van 2,5 mm naar 2,0 mm in problematische ribben.

Poortlocatie verplaatst van rand naar midden om stroombalans te verbeteren.

Koude sluginjectieput toegevoegd en ventileren geoptimaliseerd.

Gemeten resultaten:

Eerste-doorloop rendement: 98.2%(tegenover 86,5% voor de wijzigingen)

Gemiddelde cyclus tijd: 26,5 s (afgenomen van 34 s)

Dimensionele Cpk op 3 kritieke afmetingen: ≥1.67binnen 500 monsters

Nabewerkingspercentage: <0.5%

Notities: monsteromvang, meetmethoden en inspectie-instrumenten (CMM met 2 µm resolutie) zijn gedocumenteerd in het proefrapport dat bij de levering wordt geleverd.

Gietstaalsoorten: P20, H13, S136, 1.2344 — specificeren op basis van slijtage, polijstbehoeften en productievolume.

Oppervlakteafwerkingen: SPI A/B voor glanzende onderdelen, structuurafwerkingen met monsterpanelen geleverd.

Standaardtoleranties: ±0,05 mm voor de meeste thermoplastische onderdelen; kleinere toleranties mogelijk via nabewerking na het gieten indien vereist.

Inspectie: ISO 2859-steekproefneming, CMM-rapporten, functionele tests.

Prototype aluminiummatrijs: typische productietijd 7–14 werkdagen; matrijskosten zijn afhankelijk van het aantal caviteiten en complexiteit.

Geharde stalen productiematrijs: typische productietijd 6–10 weken, afhankelijk van complexiteit en levertijd van het staal.

Kostenfactoren: aantal caviteiten, staalkwaliteit, inspringingen, verwachte levensduur (×100 duizend tot miljoenen), EDM/precisie-oppervlakte-eisen.

Inclusief postkosten: gereedschap, validatie, run-off en productiekosten per onderdeel bij gegeven volume.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. Alle rechten voorbehouden — Privacybeleid—BLOG