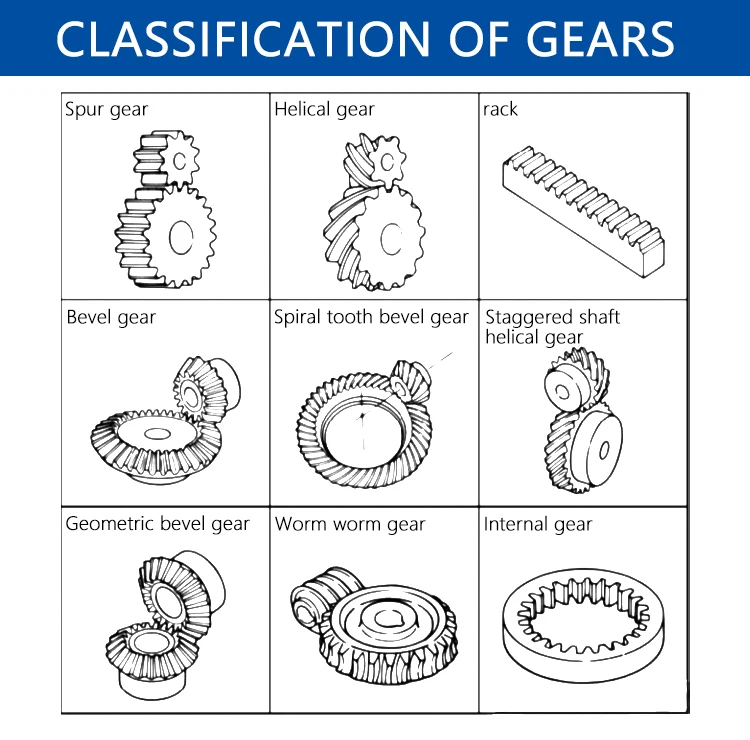

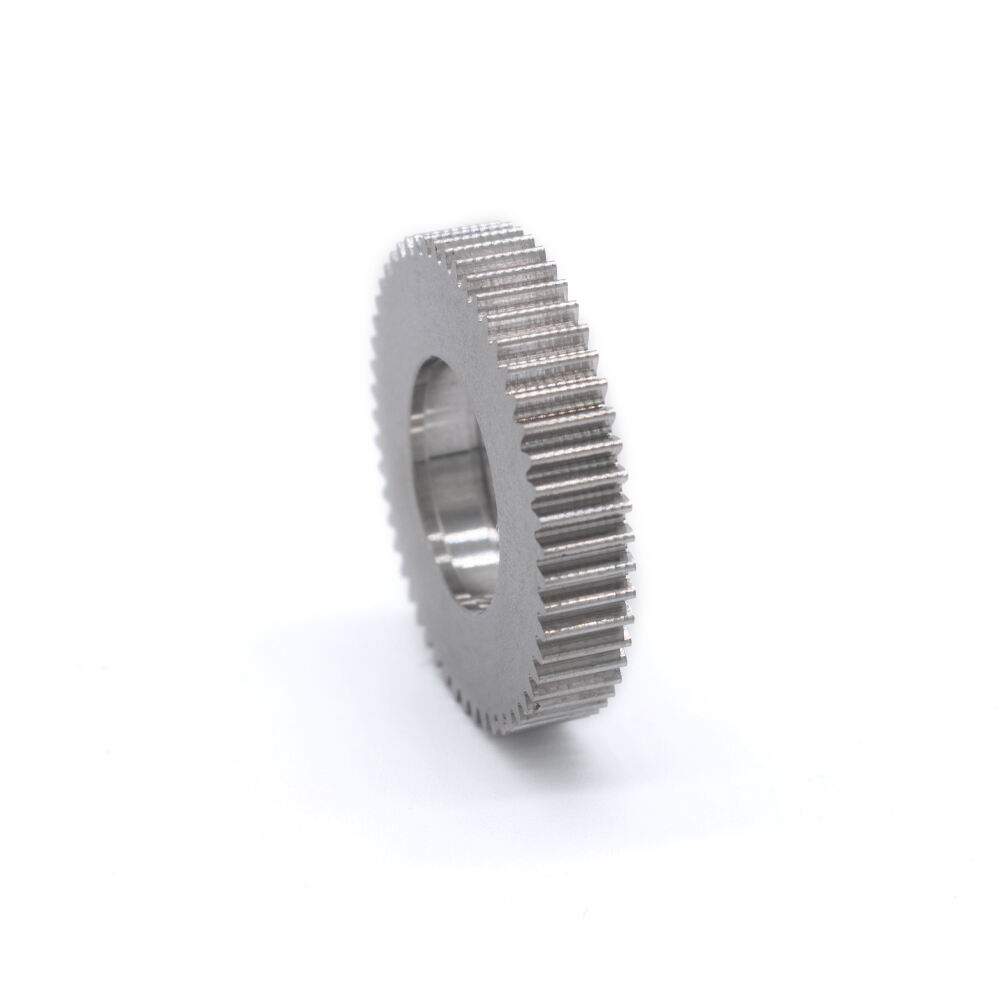

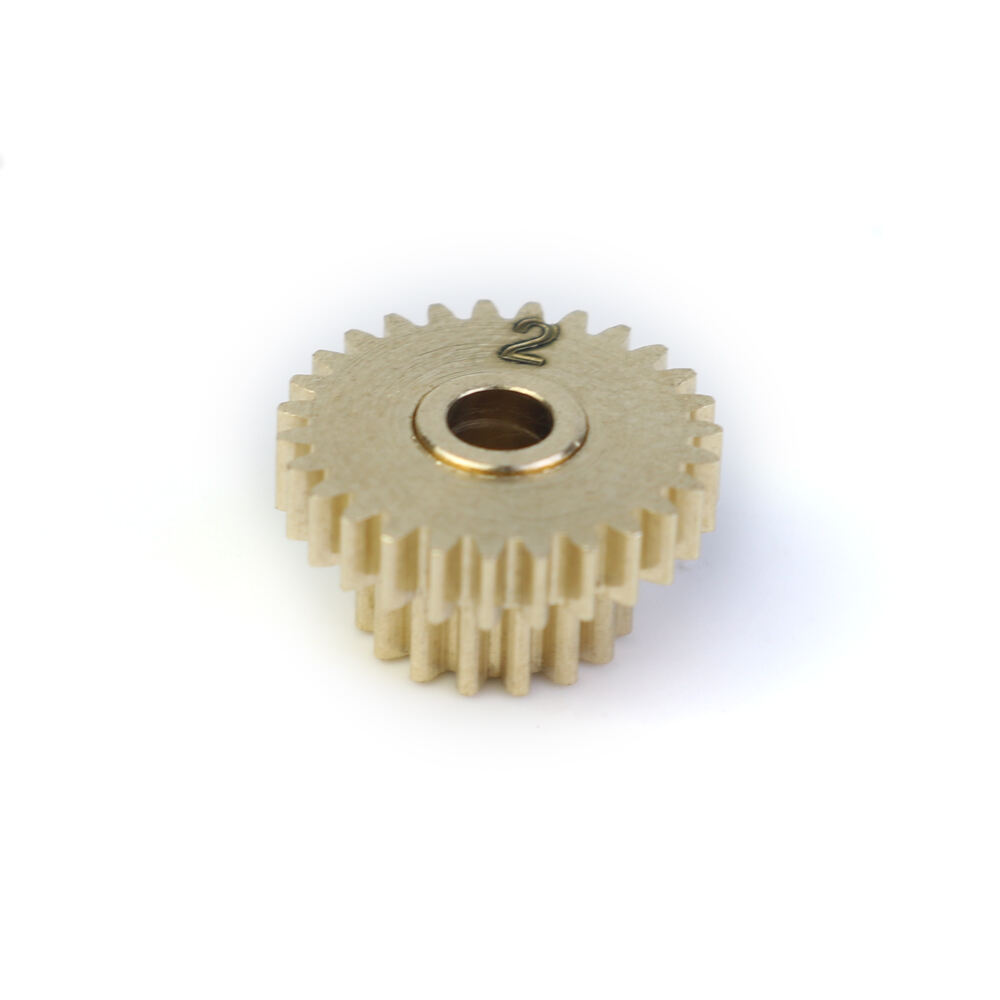

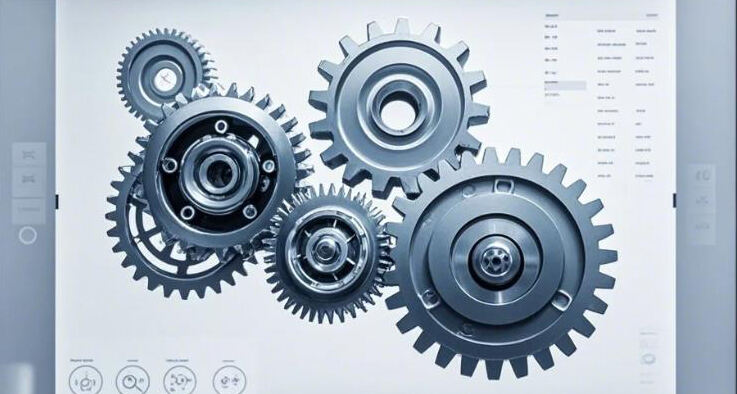

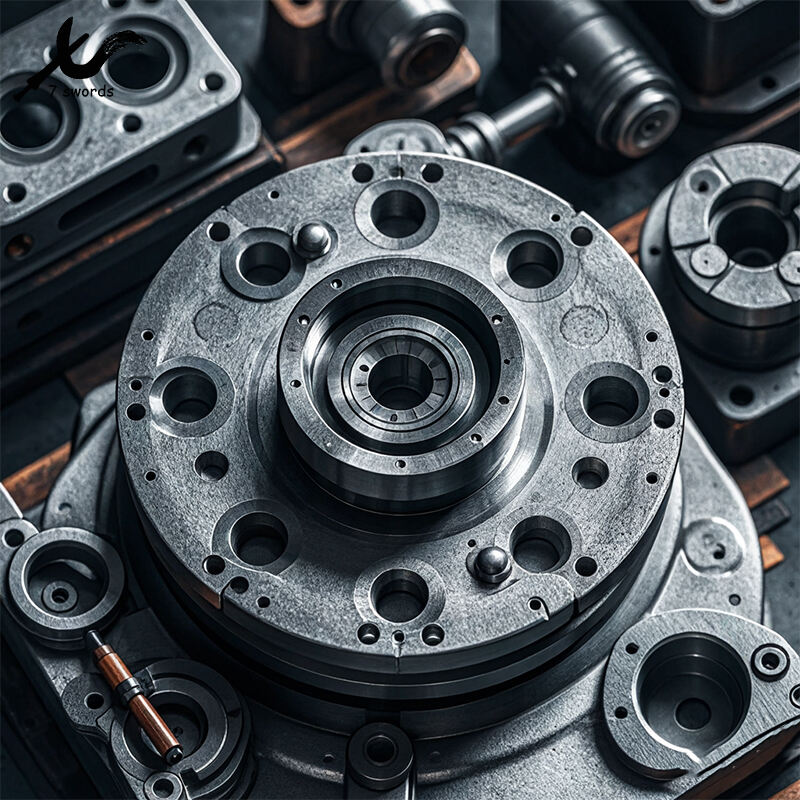

Swords Precision is a trusted brand in the realm of gear machining, specializing in the production of custom precision industrial gears made from steel, brass, and plastic. As leading manufacturers and suppliers, Swords Precision takes pride in offering a wide variety of gears including spur, small, large, helical, and spur gears to meet the specific needs of their clients.

With a commitment to quality and precision, Swords Precision ensures that each gear is manufactured with the highest level of accuracy and attention to detail. Their team of experienced engineers and machinists utilize state-of-the-art technology and machinery to produce gears that meet the strictest industry standards.

Whether you are in need of gears for automotive, aerospace, or industrial applications, Swords Precision has the expertise and capabilities to deliver custom gears that are tailored to your unique requirements. Their spur gears are known for their durability and performance, making them ideal for high-stress applications where precision is crucial.

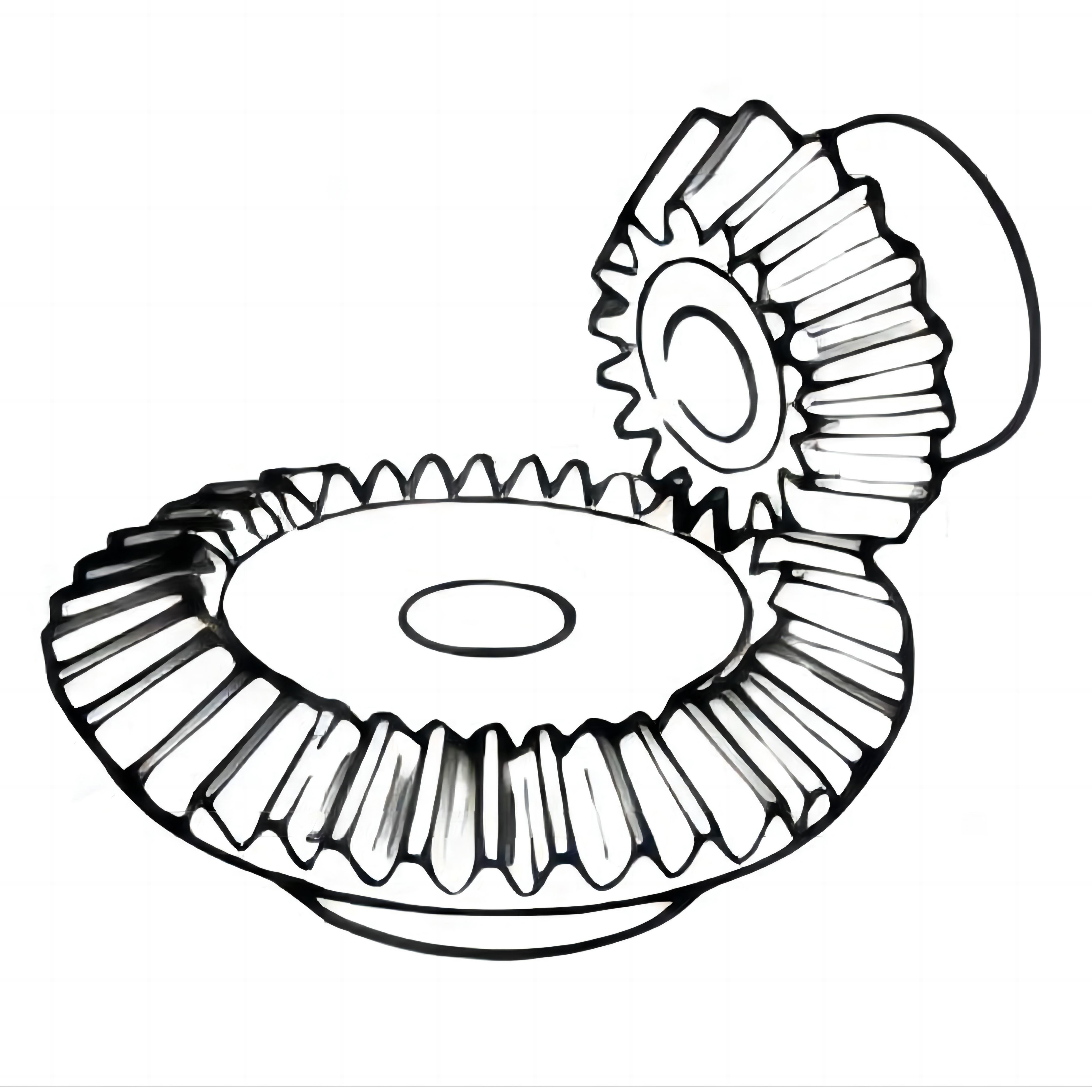

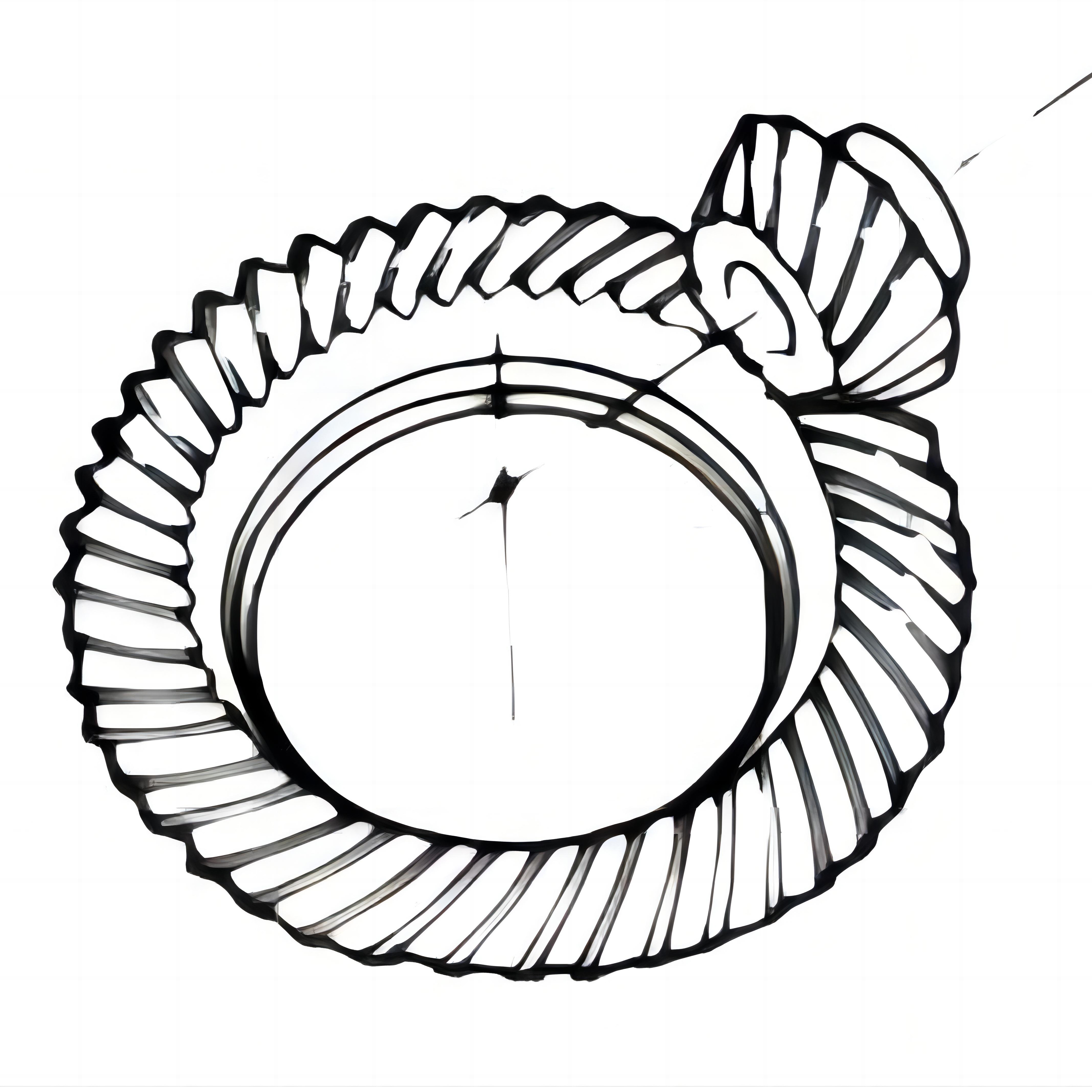

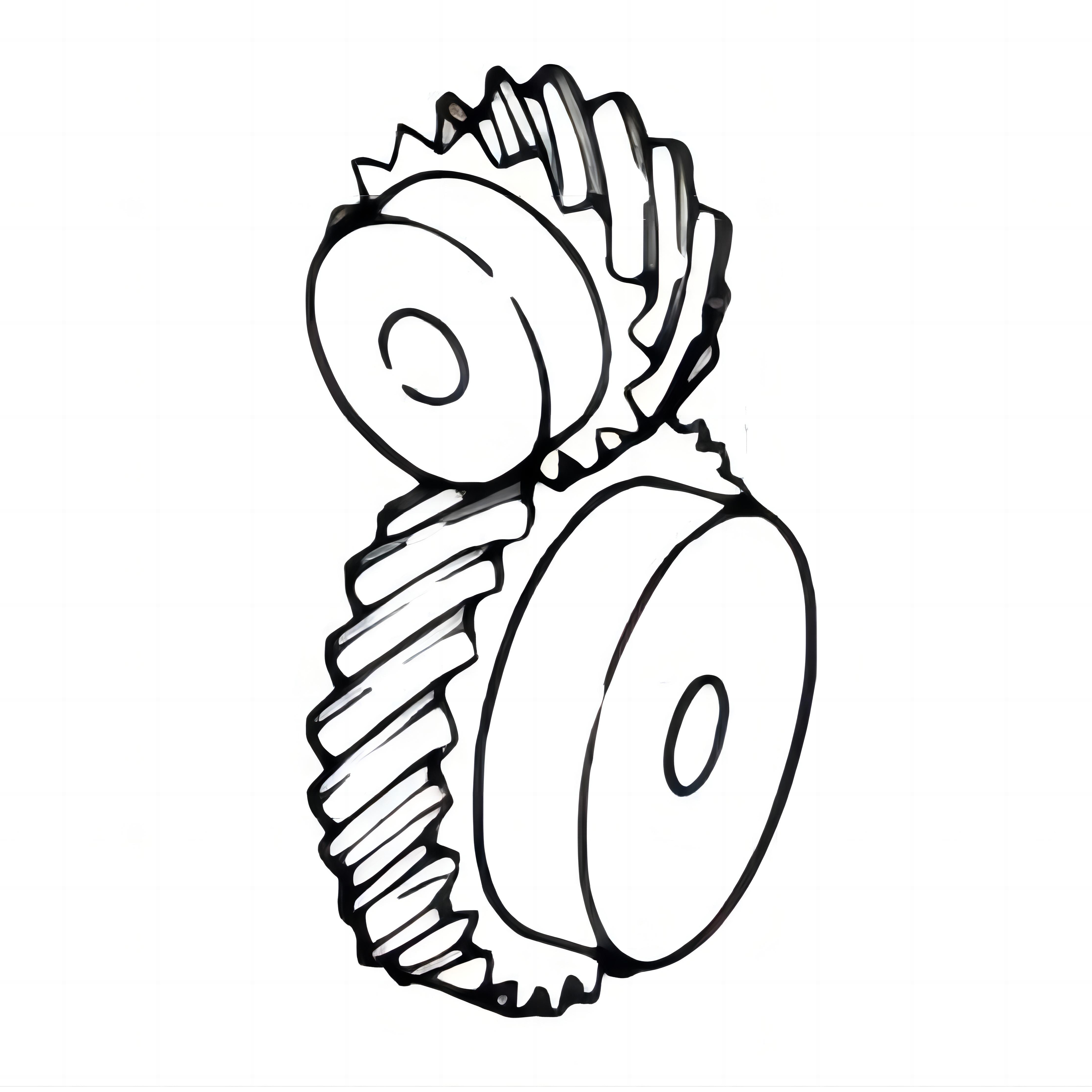

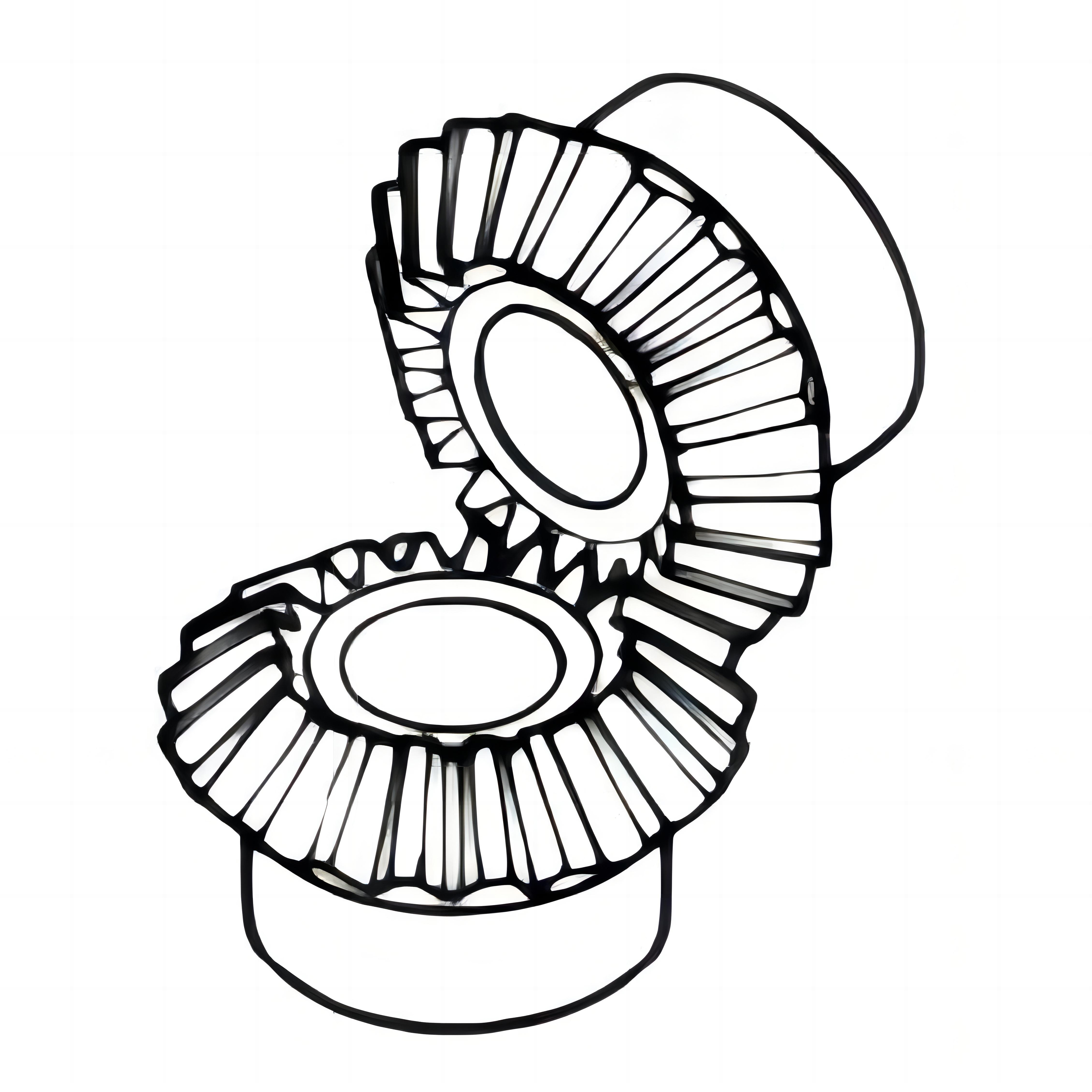

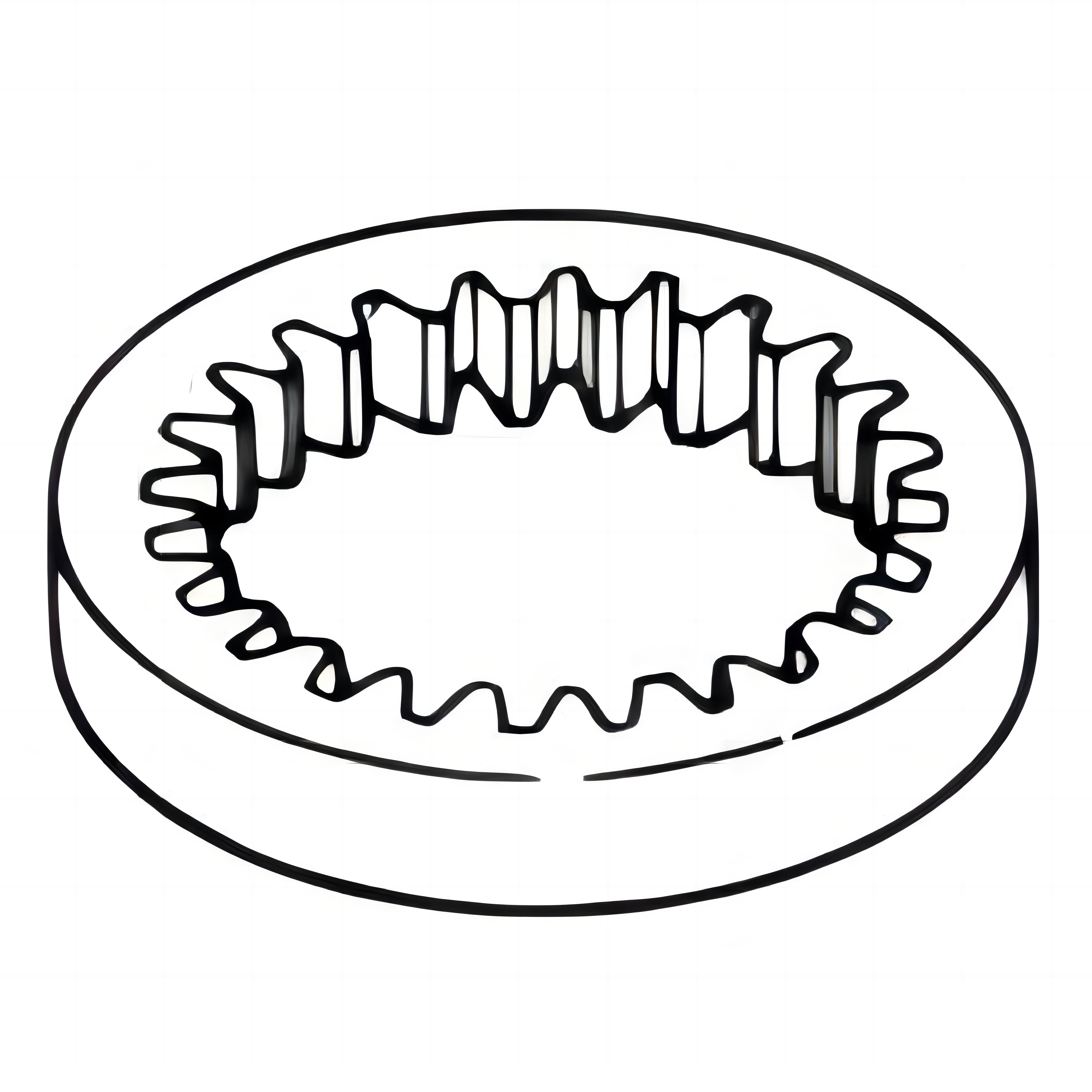

In addition to spur gears, Swords Precision also offers small and large gears that are designed to handle heavy loads and provide smooth and efficient power transmission. Their helical gears boast superior strength and quieter operation, making them a popular choice for a wide range of applications.

Swords Precision understands the importance of customization and flexibility when it comes to gear manufacturing. That is why they work closely with their clients to develop gears that are specifically engineered to meet their exact specifications. Whether you need a single prototype or a large production run, Swords Precision has the capabilities to fulfill your order in a timely and cost-effective manner.

When it comes to gear machining, Swords Precision sets the bar high for quality, reliability, and precision. With a commitment to excellence and customer satisfaction, they have earned a reputation as a top choice for industrial gears among manufacturers and suppliers worldwide. Trust Swords Precision for all your gear machining needs and experience the difference that precision engineering can make

Staggered Shafthelical Gear

Material Selection and Options

The material of the gear plays a significant role in its durability, load-bearing capacity, and efficiency. Provide details about the materials you offer, such as:

* Steel: High-strength and durable, often used for heavy-duty gears

* Stainless Steel: Resistant to corrosion, ideal for food processing and marine environments

* Aluminum: Lightweight, corrosion-resistant, and ideal for low-load applications

* Brass/Bronze: Corrosion-resistant and self-lubricating, often used for precision gears

* Plastic (Nylon, Acetal): Used for lighter applications with low to moderate loads and where noise reduction is needed

* Cast Iron: Commonly used for larger gears and those requiring high wear resistance

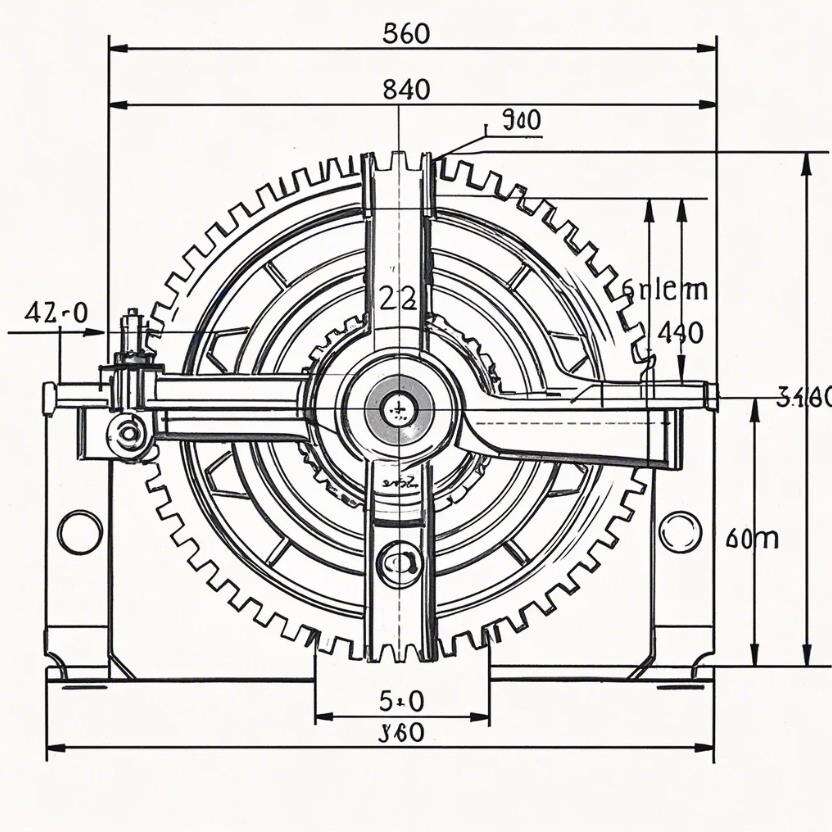

Gear Specifications

* Module / Diametral Pitch: This refers to the size of the teeth and is critical for ensuring that gears mesh properly. Provide both the module (metric system) and diametral pitch (imperial system) options.

* Pitch Circle Diameter (PCD): The diameter of the circle on which the gear teeth are distributed.

* Number of Teeth: This defines the size and gear ratio, affecting torque and speed.

* Pressure Angle: The angle at which the gear teeth engage, typically 20° or 14.5° for standard gears.

* Face Width: The width of the gear’s teeth along the axis.

* Pitch: The distance between adjacent teeth along the circumference of the gear.

* Bore and Keyway Sizes: Specify the inner hole diameter and keyway dimensions to ensure proper fitting onto shafts

Surface Treatment and Finishing

Surface treatments improve the gear’s strength, wear resistance, and performance. Common surface treatments include:

* Heat Treatment: To increase hardness and wear resistance (like carburizing, induction hardening).

* Nitriding: A process to improve surface hardness and reduce friction

* Coatings: Such as zinc plating, nickel plating, or DLC (diamond-like carbon) coatings to reduce wear and enhance corrosion resistance

* Grinding/Polishing: To achieve precise finishes and minimize friction between meshing gears

Manufacturing Processes for Gears

1. Hobbing: A process that uses a cutting tool called a hob to create gear teeth. This is commonly used for making spur, helical, and worm gears

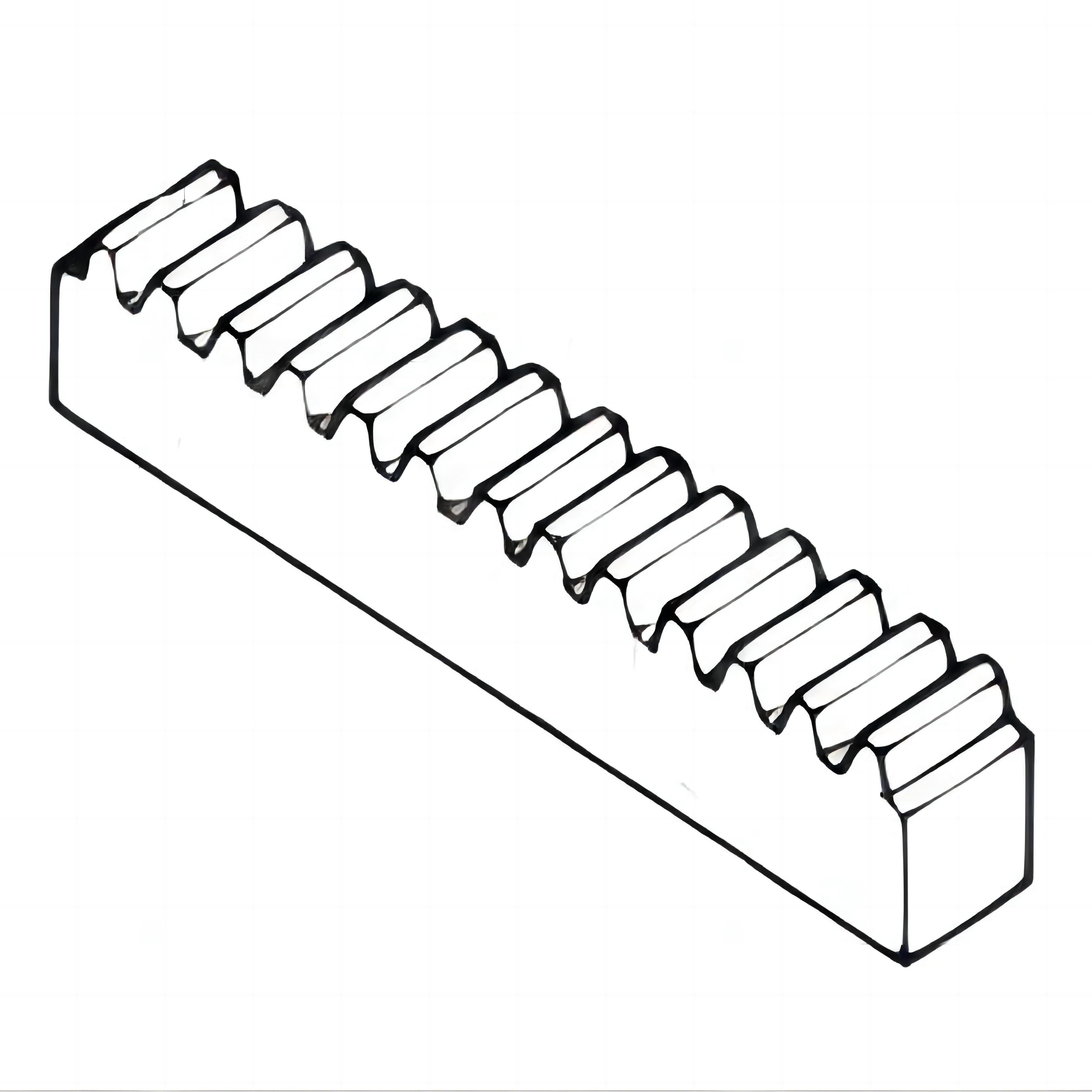

2. Shaping: A method where a cutting tool with the profile of the gear’s teeth moves across the workpiece, ideal for internal gears and racks

3. Grinding: Used for finishing high-precision gears, grinding enhances the gear’s surface finish and dimensional accuracy

4. Casting: Typically used for manufacturing larger gears or when material properties such as weight reduction are a priority. Common in automotive and aerospace applications

5. Forging: A process that uses pressure to shape a gear blank, followed by machining. Forged gears are known for their strength and durability

Custom Gear Solutions and Design Services

Provide details about your ability to handle custom gear manufacturing. Offer the following:CAD Modeling: Include CAD (Computer-Aided Design) support for customers who want to submit their designs or receive assistance in developing them

Prototyping: Provide quick-turn prototyping services for proof of concept or small production runs

Consultation: Provide gears details to customize your personal gears

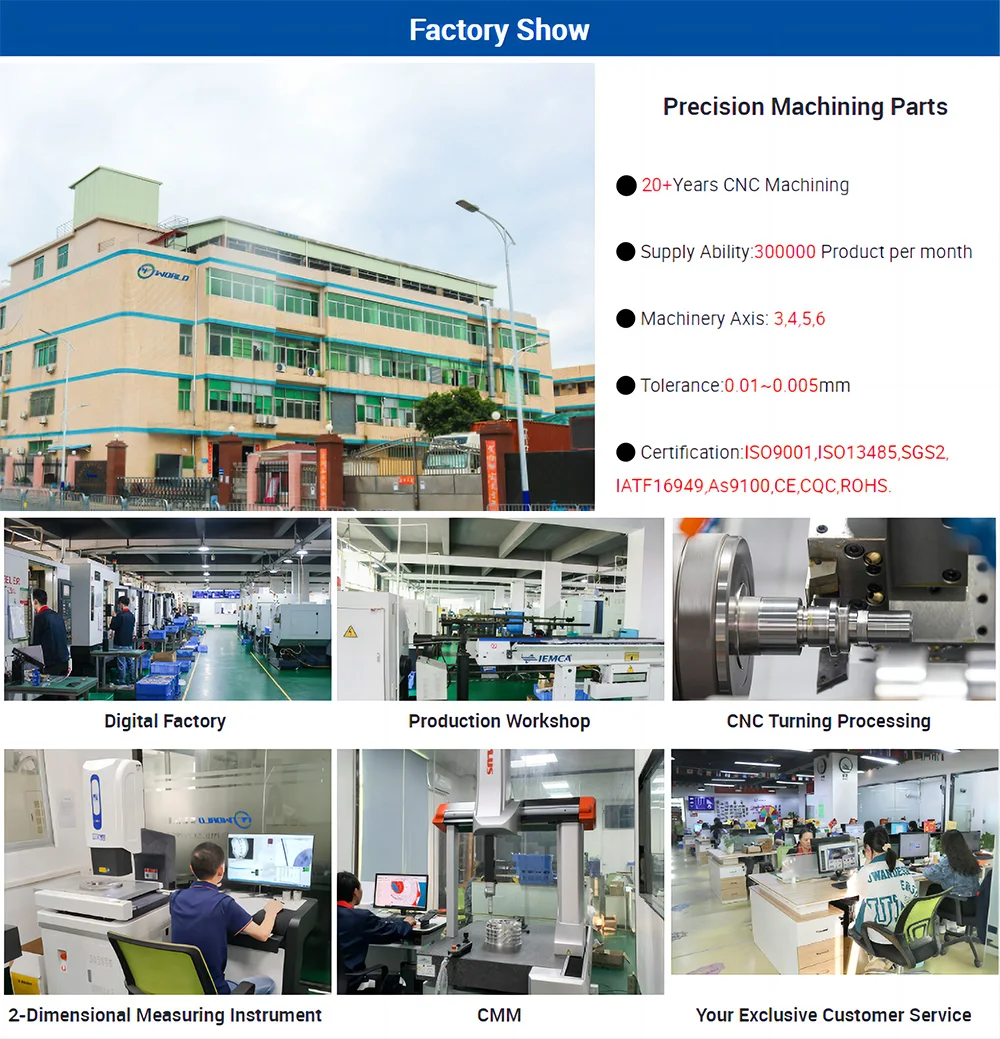

Precision Machining Parts

20+Years CNC Machining

Supply Ability:300000Pieces/Month

Machinery Axis:

3,4,5,6Tolerance:+/-0.01~+/-0.005mm

Certification:ISO9001, ISO13485, SGS2, IATF16949, As9100, CQC, ROHSWe are engaged in precision mould, CNC turning parts, CNC milling parts. Our products are mainly used for industrial equipments and medical equipments. We can make products with material of stainless steel, steel alloy, copper, aluminum, PEEK, bronze alloy, nylon, Derlin, PTFE etc. The surface treatment we can handle is anodize, black oxide, powder coating, high polishing and plating. In order to make sure the critical dimensions, we import our machines from USA and Japan. The minimum tolerance we can make is 0.005-0.01millimetre. Our engineers are quite experienced and can supply OEM service or can give some advices when you need. Our works are trained and follow ISO standard. Choose us PERFECT, we will exceed your expectation. So if anything we can help or any further information you need, please don't hesitate to contact us

Your Exclusive Customer Service

1. Are you a manufacturer or a trading company

We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports

2. How to get a quoteDetailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information

3. Can I get a quotation without drawings

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation

4. Can you provide samples before mass production

Of course, the sample fee is necessary. If possible, it will be returned during mass production

5. What is the delivery date

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks

6. How do you control quality

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week